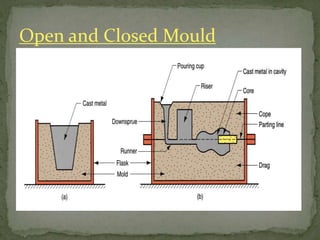

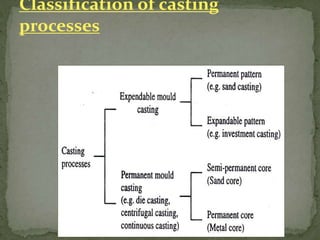

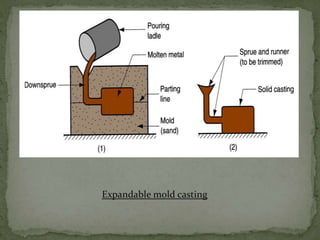

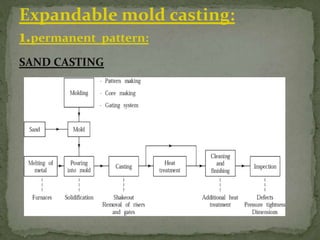

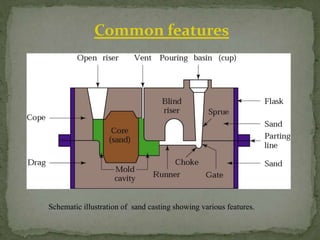

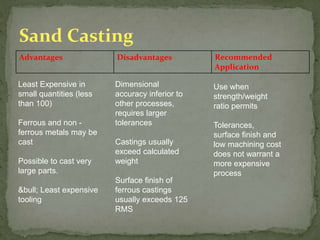

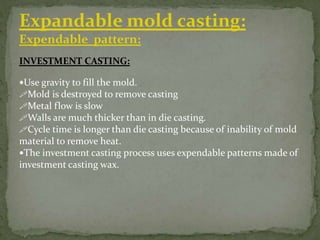

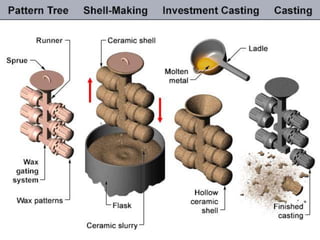

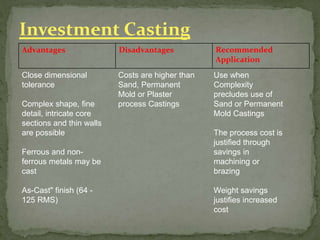

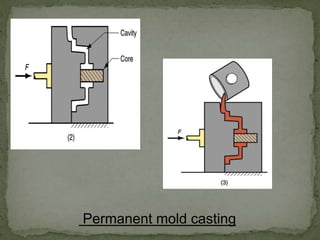

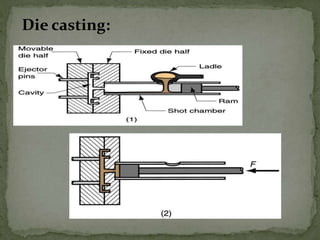

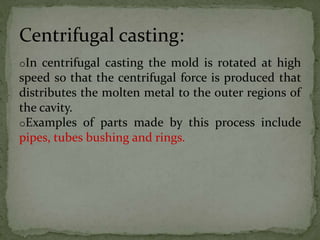

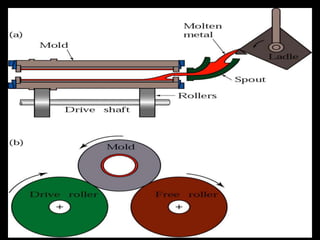

The document provides an overview of the metal casting process. It discusses the history and basic features of casting, including the types of molds used. The main casting processes are classified as either expandable mold casting (such as sand casting) or permanent mold casting (such as die casting and centrifugal casting). Sand casting uses expendable sand molds, while die casting uses reusable steel dies and forces molten metal into the mold under high pressure. Selection of the appropriate casting process depends on factors like alloy, size, shape, tolerance, and economics of machining versus production costs.