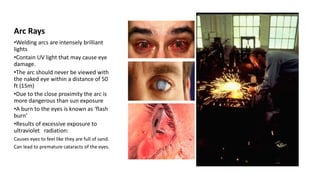

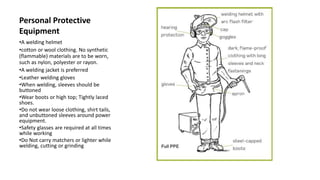

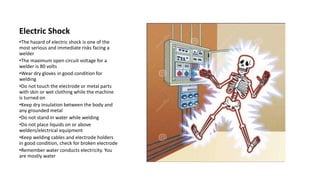

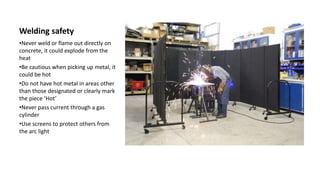

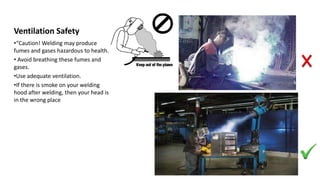

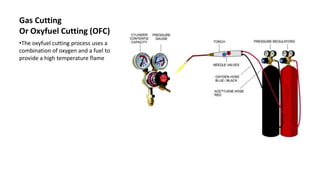

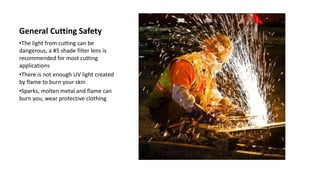

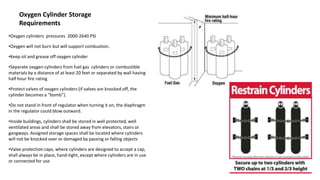

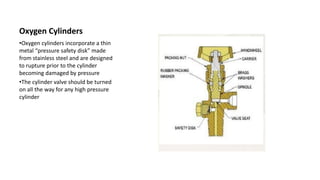

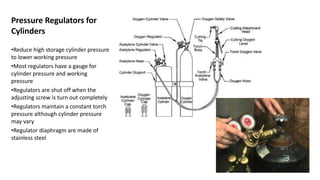

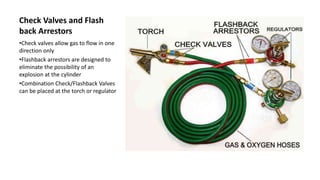

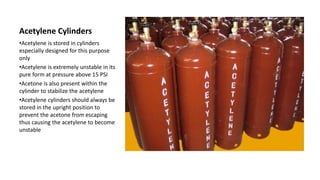

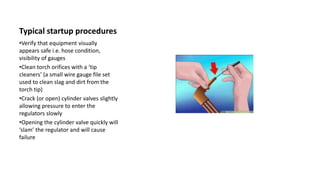

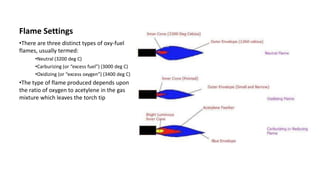

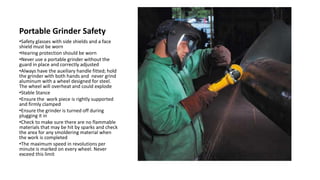

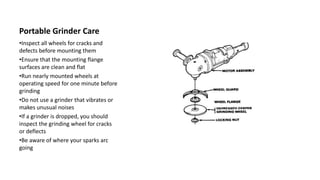

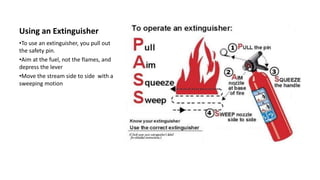

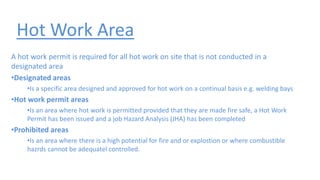

This document outlines welding and cutting safety procedures. It discusses the risks of arc rays and UV light from welding, and emphasizes the importance of wearing appropriate protective equipment like welding helmets, gloves, and clothing. It also covers electric shock hazards, ventilation requirements, gas cylinder safety, fire watches, and emergency procedures in the event of a fire. Proper personal protective equipment, machine maintenance, ventilation, and following permit requirements are essential for welding and cutting safety.