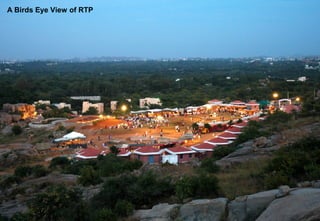

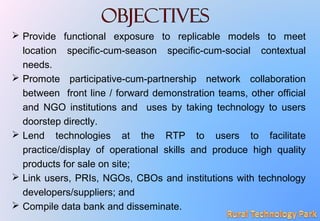

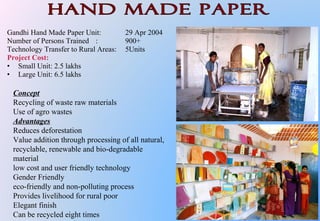

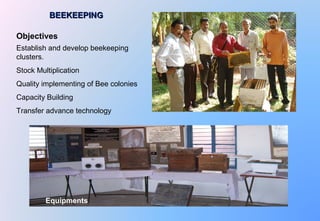

This document provides information on the Rural Technology Park (RTP) operated by the National Institute of Rural Development. The RTP aims to accelerate dissemination of appropriate technologies to rural communities to improve livelihoods and quality of life. It focuses on demonstration and sharing of technologies related to water, farming, fisheries, food processing, housing, energy and more. The RTP collaborates with various partners to promote selected technologies and provides training and support for their adoption. It also outlines criteria for selecting technologies and provides examples of specific technologies that have been promoted through the RTP.