Embed presentation

Downloaded 188 times

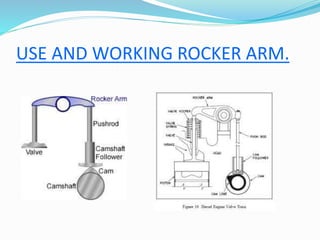

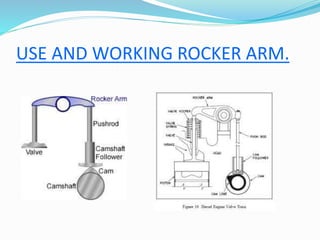

A rocker arm is an oscillating lever in internal combustion engines that translates radial motion from the cam lobe into linear motion to open a poppet valve. It operates by moving one end to press down on the valve stem while the other end is acted upon by the camshaft's rotation. Various materials, including steel and cast iron, are used in rocker arms, with design considerations focused on reducing weight to enhance engine performance at high speeds.