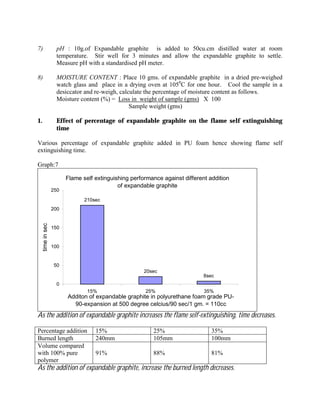

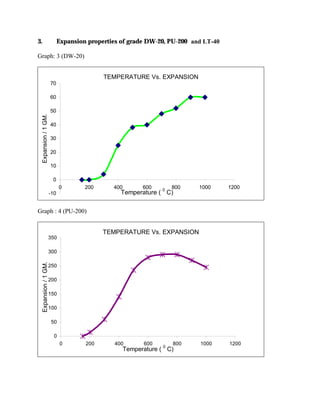

This document discusses the use of expandable graphite as a non-halogenated flame retardant in flexible polyurethane foam. It describes how expandable graphite is manufactured using natural graphite flakes that are oxidized to become intercalated and expand up to 100 times their original volume when heated. The key properties required for it to effectively act as a flame retardant are low expansion temperatures around 300-500°C to match the critical temperature of polyurethane decomposition. Experimental results show that expansion rate and flame retardant performance increase with higher graphite purity, larger flake size, and carbon content. When added to polyurethane foam and exposed to heat, expanded graphite forms a char that

![ExperimentalExperimentalExperimentalExperimental

Materials and methods:

The raw material used in the work were polyol (Avg mol wt 3500) T.D.I, stannous octate, Amine

(DABCO), silicon polymer, water, & expandable graphite.

For the experiments we used the expandable graphite manufactured by Cleanline Products

Private Limited, Pune, India9

.

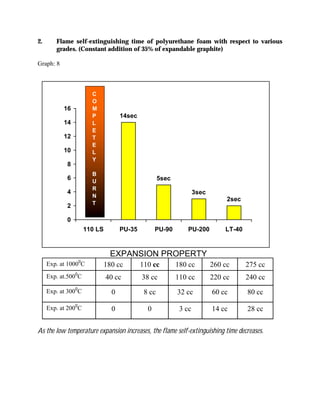

Typical Analysis of ExpandaTypical Analysis of ExpandaTypical Analysis of ExpandaTypical Analysis of Expandable Graphiteble Graphiteble Graphiteble Graphite

PROPERTIES G R A D E S

110 LS PU-35 PU-90 PU-200 LT-40

Expansion at

10000

C

180 cc 110 cc 180 cc 260 cc 275 cc

Expansion at

5000

C

40 cc 38 cc 110 cc 220 cc 240 cc

Expansion at

3000

C

0 8 cc 32 cc 60 cc 80 cc

Expansion at

2000

C

0 0 3 cc 14 cc 28 cc

pH 07.13 07.25 07.07 07.12 07.18

Moisture 0% 0% 0% 0% 0%

Fe, Cu & Ni Nil Nil Nil Nil Nil

Mesh (B.S.S.)

+ 22 # 06 % 00 % 00 % 02 % 10 %

+ 36 # 46 % 22 % 22 % 38 % 58 %

+ 44 # 27 % 10 % 10 % 25 % 06 %

+ 52 # 04 % 12 % 12 % 12 % 05 %

+ 60 # 09 % 23 % 23 % 09 % 06%

+ 85 # 05 % 15 % 15 % 06 % 07 %

+ 100 # 03 % 09 % 09 % 02 % 08 %

+ 150 # 09 % 09 % 06 %

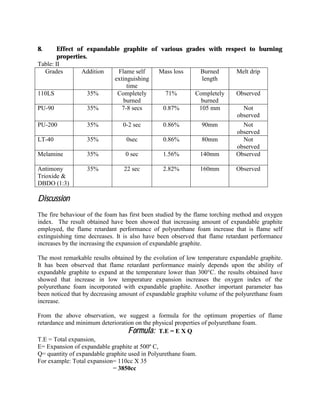

Polyurethane foam formulation:

[ parts by wt. ]

Polyol Average Mol. Wt. 3500 : 100.00

Expandable Graphite : 35.00

Water : 3.00

Silicon Polymer : 1.20

Amine (DABCO) : 1.20

Stannous Octate : 0.23

Isocyanate (TDI) : 48.66](https://image.slidesharecdn.com/b31cb6a3-e6e6-482a-9db9-dd7529a369e6-161220101513/85/PU-FOAM-8-320.jpg)

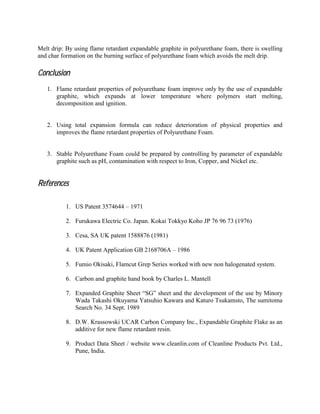

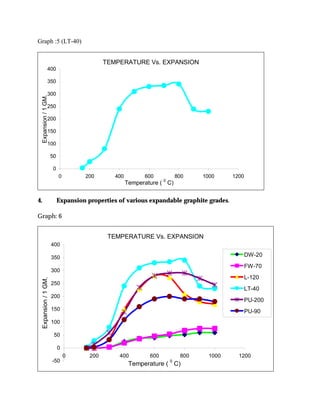

![Preparation:

The foam was prepared by hand mixing technique. Polyol is mixed with expandable graphite at

4000 rpm, then water, silicon polymer, Dabco( amine), Stannous octate are added with constant

stirring, finally T.D.I. is added with constant stirring and poured into the cardboard box. Foam

cured at room temperature for 24 hours (room temperature= 30°C) and then used for testing.

Test methods:

1) BURNING PROPERTY : Flame retardant properties were measured by flame torch

method (Flame height - 2 ½ inch blue flame of Bunsen burner, 20 sec torching time,

angle 45°) and oxygen index of expandable graphite is measured by standard method

ISO-4589-1984(E).

2) EXPANSION : Dry the expandable graphite at 1050

C for one hour. Accurately weigh

0.75 gm, of the dried expandable graphite in to a dried, 100 cu-cm Nickel crucible and

place in a furnace at 5000

C for 90sec and then allowed to cool in a desiccator. Pour

expanded graphite in to dried measuring cylinder with out disturbing expanded crystals

and measure the volume of the expanded graphite without tapping. Then calculate the

expansion of 0.75 gm to 1 gm. Expansion = Expansion per gram

Sample weight

3) FIX CARBON: is calculated by the following formula = [100 - (Ash + Volatile Matter)]

4) ASH CONTENT : Dry the expandable graphite for one hour at 1050

C, place 0.300 gm.

of expandable graphite in a dried, pre-weighed crucible preferably platinum

crucible. Place in furnace for 3 ½ Hrs. at 9500

C or until fully ash that is at constant

weight. Re-weigh the remaining ash and calculate the ash content as a percentage of the

original weight of expandable graphite.

Ash Content (%) = Loss in weight of sample (gms) X 100

Sample weight (gms)

5) VOLATILE MATTER : About 1gm sample before heat treatment is weighed by an

analytical balance. It is then put in a Nickel crucible. The Nickel crucible is covered

with a lid and place in electric furnace at 9250

C + 200

C for 7 minutes. Then nickel

crucible is cooled in the desiccator and is weighed by an analytical balance. The volatile

matter is calculated with the help of the following formula.

Volatile matter (%) = Loss in weight of sample (gms) X 100

Sample weight (gms)

6) DENSITY : Expandable graphite is poured freely in to pre-weighed 10 cu-cm

cylinder up to 10 cu-cm marking and then weigh the cylinder again & then calculate

weight of expandable graphite. Density is calculated by following formula

Density = Mass

Volume](https://image.slidesharecdn.com/b31cb6a3-e6e6-482a-9db9-dd7529a369e6-161220101513/85/PU-FOAM-9-320.jpg)