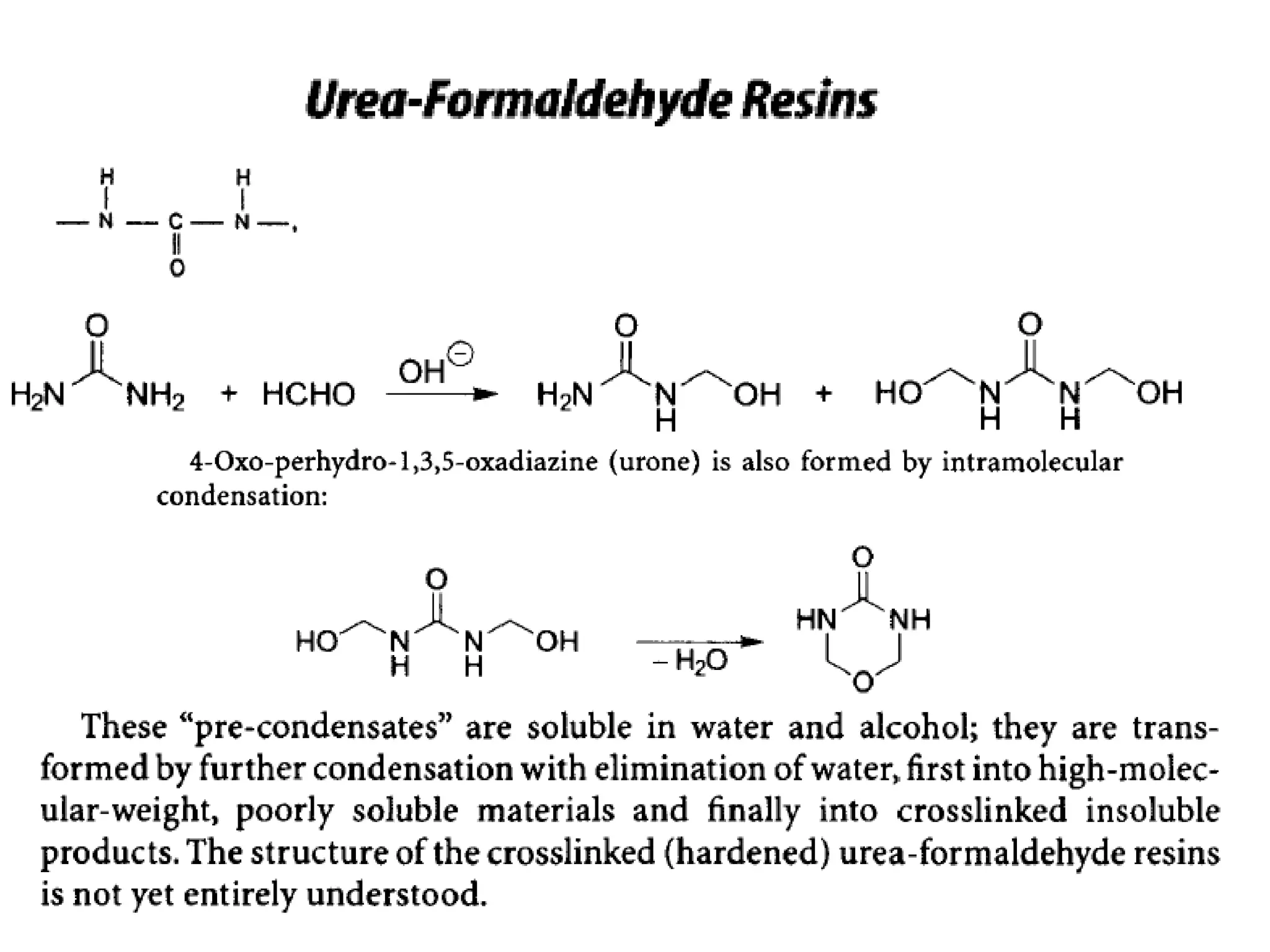

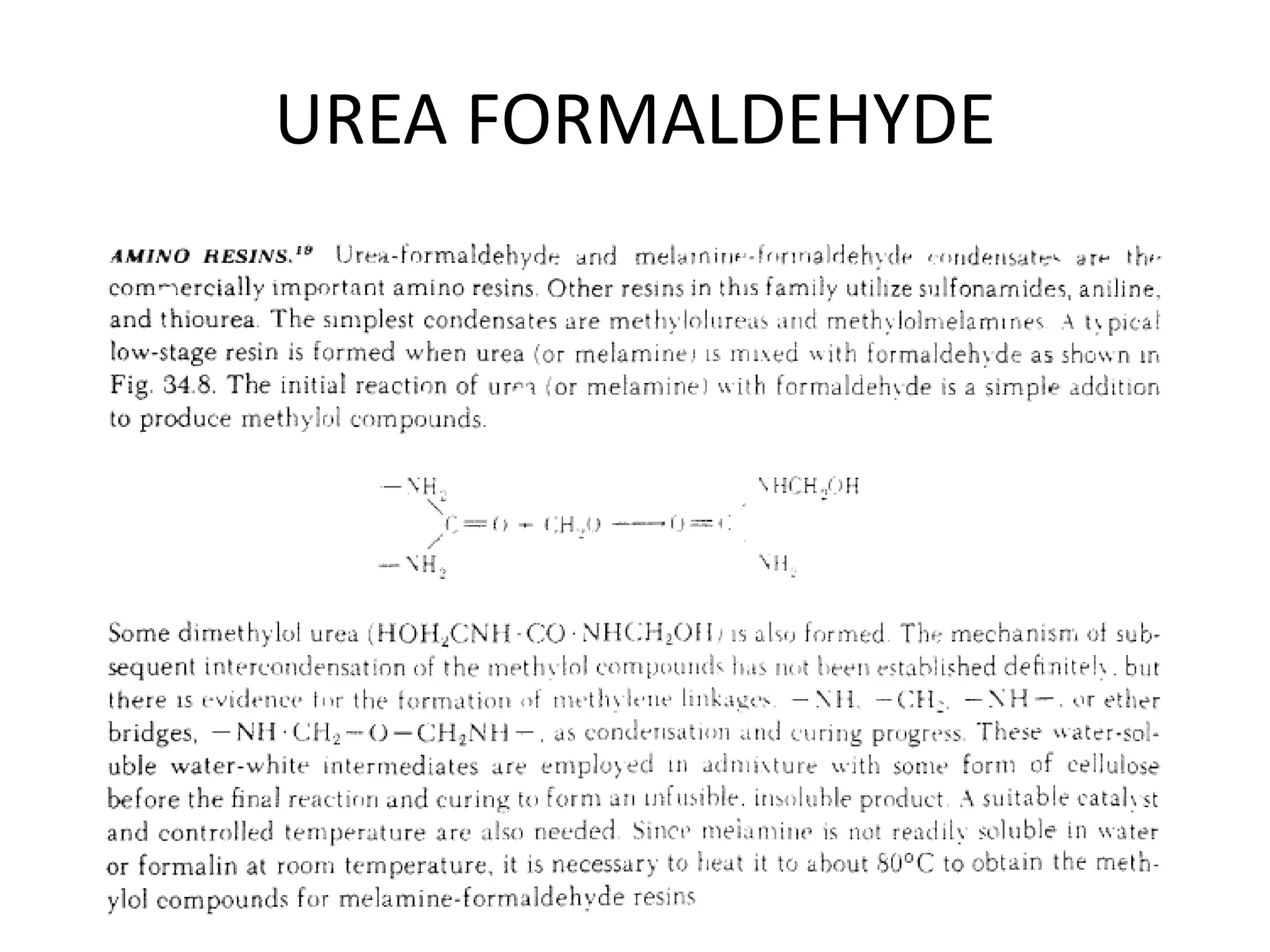

Urea formaldehyde is a thermosetting condensation polymer that is produced by reacting urea and formaldehyde in an alkaline medium. It is primarily used as a wood adhesive but also has applications as a fertilizer, foam insulation, and more. The polymerization process involves the elimination of water and results in a hard resin. However, the resin can decompose in humid conditions or at high temperatures, limiting its uses. It is manufactured through a condensation reaction of urea and formaldehyde in an aqueous alkaline solution.