Materials and Processes

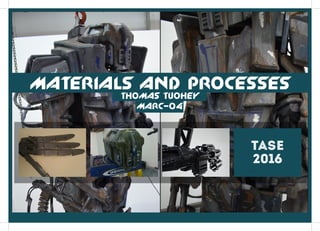

- 1. materials and processes tase 2016 thomas tuohey marc-04

- 2. contents Welding - 21 3d printing - 22 Print finishing (moulding) - 23 Print finsishing (paint) - 24 Coating the foam - 26 Painting (filling and base coat) - 28 Painting (colouring) - 30 Weathering (base grime) - 34 Weathering (rust) - 35 Doodads and electronics - 36 Hands - 38 Inspirational images - 39 Completed project - 40 Materials 3 – Foam 4 – Paint 5 - Metal 6 - Glue 8 – Plastics 10 – Silicone 11 - Resin Processes 12 - Base sculpt 13 – Frame 14 – Foam fabrication 18 – CAD 20 - Laser cutting

- 3. About the marc-04 The Idea The core concept of this project was simply to trial and use as many pro- cesses as I was able to in the course of the year of work. As my skills and interest lie mostly in fabrication I chose to build a suit, utilising mainly foam fab and 3d design I taught to myself through experimentation. I chose to create my own storyline and universe for the piece to exist in as it allowed me complete control over the setting and design The materials There were two things that influenced the choice of materials in this project. Number one was what I had researched and found in terms of on- line guides and personal experience (from previous works) Number two was cost, I searched hard and anywhere I could I found cheap or free sources of materials. With the scale of the project I wanted I could have easily spent several thousand so keeping costs down was essential. The build Since so much experimentation was involved the estimates in build time fluctuated wildly. With both Thames Valley Supplies and E3D online providing materials for my project I was able to spend and focus on other aspects of my project. I pulled techniques mostly from cosplay for the foam fabrication and my previ- ous mechanical work for Dan martin provided the basis for the CAD in the hinges, features and wire controlled hands.

- 6. foam EVA Ethelene vinyl acetate is one of the most commonly used in costume and prop making at the hobbiest level, it bonds with acrylics and other paints reason- ably well along with hot glue. It’s cheap and easy to procure in floor tile form (pictured above) however larger sheets are harder to come by so large pieces must be glued together from multiple pieces. It is also harder to procure in sections thicker than 10mm, along with being an open cell foam allowing material to soak into it (can be both good and bad) Plastazote A closed cell varient of polyethelene foam similar to EVA but with a few key differences. The closed cell nature of the foam both means that it is waterproof and resistant to damage and that it is almost impos- sible to paint in a manner that has any form of dura- bility. However it is readily available in large sheets in thicknesses from 2mm-50mm along with being available in multiple hardnesses.

- 7. paint Acrylic Acrylic paint is possibly the most commonly used in an artistic manner. It is water solu- able and as such - easy to thin and clean, It can also be combined with mediums such as PVA (for flex and translucency) and various others for effects ranging from gloss to adding grit and texture, to thick- ening mediums giving the paint body and retaining brush strokes. It is comparativly very fast drying and unadulterated can be touch dry in a matter of minutes with a thin spread. Oil Oil paints are the artists classic, classi- cally using natural pigments these paints, as their name suggests, use an oil as the base for the pigment. They are much slower drying than acryl- ics, taking anywhere from a day to a week to dry. Mediums can be added to slow or speed up the drying time. Some use oils for weathering as the thin layers required allow more work time. cleaning is done with solvents. Latex Latex paints are used in latex masks, however they are far more commonly found in house paint. Both these applications take advantage of the flexibility of latex paint. As it is able to bend and flex without visible cracks or delamination from the surface. Enamel Enamel paint is most commonly seen in modelmaking and sprays, another oil based paint enamels generally have a high pigment load and a high amount of gloss- ing agent in them, self levelling even in very thin coats so that they do not show the brush strokes. This makes them great for metallics and varnishes where an impeccable surface is essential.

- 8. Metal Aluminium Aluminium has great properties in being light and strong, less known properties include extremely good temperature conduction and the fact it is extremely easy to cut and mill make it an excellent prototyping material for pieces where ease of creation and low weight is key. Steel Steel is what most people think of when they think of metals, whether it be in blades or structural objects. there are so many different grades of steel that an all encompassing definition is impossible, however they all share a few traits. - They are magnetic or can be magnetised, making it easy to create temporary attachment points. - They are easily welded into complex structures

- 9. Glue PVA Polyvinyl Acetate is a water based glue used most commonly as wood glue, however it also comes as a painting medium (for mixing with acrylics) and a release agent. It can even come as a filament for 3d printing. It can have additives to become water resistance after drying, however when wet it can be mixed with water to thin for various applications Contact cement When you need to join flexible surfaces or materials that otherwise have difficulty with adhesion. Essentially a rubber glue dissolved in a solvent base its renowned for being able to stick pretty much anything to anything, it works particularly well with foams and so is used extensivly with foam fabrication due to its quick bond time and solid connection. Cyanoacrylate Better know as super glue, these adhesives come in various thicknesses for different applications. They cure extremely quickly and have an accelorator (spray or liquid) which can cure them in seconds. They are a single part glue which cure with exposure to the air so pools of glue that are too thick will take a long time or may not even cure at all.

- 10. Printing plastic ABS Abs is one of the most popular materials to print with due to its cheapness and finishing capabilities (it can be smoothed with acetone vapor as shown above). However it emits toxic fumes while printing and has an extremely strong rate of shrinkage. Making it only possible to print on a heated bed, and even then there needs to be as little airflow around the piece as possible (Ideally a heated chamber is used). PLA The second material to be widely used by printers and possibly now the most widely used, its relativly low extrusion temperature and minimal warping combined with its ability to be printed on an unheated surface make it the go to material for printers without a heated bed and larger models that would warp with abs. It is plant based and biodegradeable along with being non toxic while printing. PET-G Polyethylene terephthalate is relativly new to the 3d printing world but outside of printing its one of the most widely used thermoplastics available. Its recently becoming much more popular due to its clarity, ease of printing with newer nozzles and mechanical strength (especially when imbued with something like carbon fiber)

- 11. Resin Polyester Polyester resin come in many varieties, most commonly is laminating resin for fiberglassing. However there are a wide range of varients such as gelcoat (thicker for building up an even first layer with good detail reten- tion), casting (for solid pieces) and a few more. All these use the same MKEP catalyst, with between 2 and 6% catalyst. It has a much longer cure time compared to polyure- thanes and is more brittle on its own. However it is much cheaper by far. polyurethane Polyurethane resins generally come as a 1:1 ratio mix, the most common of these is polyurethane casting resin, designed to be used alone or with filler powders for bulking and strength. One of the key benefits is the fast cure time. Making large produc- tion runs exponentially faster with a new piece able to be cast within 20 minutes.

- 12. silicone Platinum (addition) While being more expensive and far more picky in its use, platinum silicones have many benefits over tin silicones. Moulds made with platinum cure silicones are much more durable, deteriorating much slower and having a much higher heat resistance than tin cure, they also are food safe and as such are much safer to use on the body. In general platinum silicones also cure much faster. Tin (condensation) The cheaper of the two options for mould making/pros- thetics, generally slower to cure there are a few varients. Generally its used for mould making, with its only real benefit over platinum silicone being its lack of contami- nants. Able to cure on pretty much any clean surface. Acetoxy Easily recognised by both being commonly used in sealing bathrooms and kitchens and the pungent odor of vinegar released as it cures by releasing acetic acid. It has two main uses in SFX, it can be used raw as an adhesive to stick other silicones to fabrics (not perfect but it works). It can also be thinned with naptha then mixed with oil paints to paint silicone masks and pros- thetics.

- 13. Processes

- 14. Base sculpt I used a combination of monster clay (regular hardness), aluminium wire in various thicknesses and extruded acrylic in its various forms. As you probably notice i did not do much in the way of finishing the piece, this being a form of 3 dimensional sketch, mostly for pattern making and just getting an idea of the rough form. Lots of points changed over the course of making this, most obviously the helmet changed completely along with the design for the arm. Obviously with a project such as this lots of things will change during construction as new inspirations are found and whats practisable reveals itself over what is impractical.

- 15. Frame The framework is key in a costume suit, my original plan had clip on bracers for pretty much every limb along with a cross chest strap and waist belt, which seemed like a good idea at the start but quickly became clear that it was over engineered and added too much complexity. This was pulled back to just the bar up the back for bracing and the hooks over the shoulders for location. Since it was all being formed by hand and needed to be light, i chose aluminium as it was an ideal material. I could bend shapes by hand, drill holes easily and rivet pieces together. This way i could quickly create a very lightweight frame that held securely to my body. Whatever framework pieces i created i used 5mm plastazote to create padding, both for comfort and to protect myself from the sharp edges on the aluminium. Some were just covered with a thin layer, others were looped over so the natural spring in the material made some nice padded protection.

- 16. foam fabrication Foam fabrication has many forms, but it mainly boils down to 2 main skills, pattern cutting and Glueing. You can see that the design stuck quite firmly to the initial sculpt for the back piece as that was the first bit I made. As it moved around details I liked popped out and details that didnt work were hidden or replaced If I had known how much I would need in the end i would have bulk bought evo stick impact, as it was i went through probably 2 liters of the stuff.

- 17. Almost always i will start with a cardboard template for a piece, this allows me to a) check the fit against what has already been made and b) trace and cut out multiples for repeating shapes. It also helps when making symmetrical objects as you can trace the shape then flip along one line and trace the edge again, creating an evenly shaped object. Edges that will be bevelled are done before attaching to the armour, I do this either by placing the edge to be bevelled against the cutting mat or using a ruler to guide a scalple along an edge. Curved surfaces or parts already on the armour are generally done free hand, its less accurate but with practise you can get nice clean lines, by the end of it I was doing 90% free handed. As always, everything is joined together with contact adhesive, taking care that the seams line up exactly. It is always good to check your fit as you go along.

- 20. CAD (computer aided design) CAD can be done with a myriad of programs, costing anything from nothing to a thousand pounds. I used Autodesks Inventor as they graciously provide almost all their programs for free to students, after uni I will probably be relearning and switching to fusion 360 as its a similar style of program but free if you earn under a certain amount. This is a little bolt detail you can see on the shoulder of the completed suit. Step 1) A “sketch” is done to create the base form, Step 2) Then the piece is revolved to created a round form. other times a piece can be extruded to create a flat object with the sketches silouette. Step 3) A detail is extruded into the surface from a second sketch, the depth set to not create a hole Step 4) The hexagons edges are chamfered and the outer ring is filleted to create a more bolt like appearance Step 5) This one is optional, but you can render the finished design in various materials, this is useful for display purposes.

- 21. 2d cad display One of the easiest ways to display 3d models for appraisal and review is with a 2d “drawing”. As many people dont have access to the necessary programs required to view 3d models but nearly everyone can view a simple image file from any device with a screen. Seen here are (clockwise from bottom left) Arm cannon - Printed in multiple parts and based around two PVC tubes, when fit- ting parts together you need to account for shrinkage and the inherant innacuracy in desktop 3d printing Hand base - This piece along with the fingers probably had the most revisions, go- ing through multiple mechanical test printings before settling on the design used in the final piece. still plan on working on it to fine tune it a lot more. Doodad 3 - Not used in the end, but a quick detail which took about 20 minutes to design.

- 22. lasercutting I started the lasercutting by creating a 3d model with the laser cutting in mind, this meant creating all flat pieces of certain thicknesses. In my case I was doing it all from 4mm mild steel so each section of the model was created with this in mind. I then was able to export each flat section into a DWG file and fix any errors or double lines before sending it off the the laser cutters. When sending off those files you need to take into account all the specifics of the material such as mild or stainless steel, thickness, heat treating and a whole host more. I was able to rely on the cutting place I used to give me advice on what would work best. A few days later i received a pallette of cut parts, designed to easily slot into eachother an be welded together (along with scaling calipers which i designed myself and sold to other students)

- 23. 90% of welding boils down to 3 main types, MIG TIG and Stick. As my pieces were designed to slot together I could have used any, but due to its speed and ease of use i went with MIG. Seen above are my practice pieces, the assembled front claws and the completed stilts. MIG - Metal Inert Gas, electrical current is fed through a metal wire which runs down a cord to the hand held unit. At a press of a button this unit sends the current through while advancing the wire. All while shrouding the welding zone with an oxygen shielding inert gas, usually argon. TIG - Tungsten Inert Gas, almost the same process as with mig, however the electrical current is instead directed through a tungsten electrode to heat the area of the piece. then welding wire is fed by hand into the heated area. Stick - The current, welding wire and shield are all combined in a stick of material which is clamped in an electrode attached to the welder, as the current flows through the stick into the piece the shield melts as well and floats on top of the molten metal, shielding it from oxygen. This needs to be chipped off afterwards. welding

- 24. 3d printing An evolving dicipline that I very much enjoy being a part of, 3d printing has been around on an industrial scale for a long time. However in recent years it has been possible to build or buy a printer for relativly miniscule amounts of money, admittedly the detail on these products is not on par with industrial scale machines but as i can design a part and have a prototype within a few hours it allows me to do multiple designs and trials for relativly little money (14 prototype fingers will cost around 20 gbp in materials) To the left is a single finger as it comes off the printer, above is the tool path which shows where the print head will move. Settings such as layer height, print head/ heated bed, print speed and material type all affect surface quality and strength.

- 25. One of the ways I used prints in this piece was by going through a process to end up with a cold cast resin piece. Starting with a raw print, I did some basic cleanup then sprayed on several coats of filler primer to fill the spaces in the layers, this was then sanded down and another layer applied and repeated until I was happy with the surface finish. A simple block mould was then made from foam core, hot glue and tin silicone. Once cured this was filled with a mix of aluminium powder and polyurethane fast cast resin (know as cold casting), this mix can be polished like metal. print finishing (moulding)

- 26. Print finishing (sand and paint) If only one of each piece is required (or a minimal amount) it can make more sense to simply do the repeated layers of filler primer and sanding followed by a base colour and then finishing. This can also take advantage of the structual strength of printing plastics which on average are higher than the most common range of castable resins.

- 28. Coating the foam Plastazote is a great material for fabrication, available in large sheets and many different thicknesses its perfect save for one point. Being a closed cell polyethelene foam it has trouble bonding with glues and paints, with most just flaking right off. On top of this it has the effect on paint that all foams do where the finish becomes porous. Others such as James Brunton on xrobots.com have done a good coating on it using a high shore hardness resin, this essentially creates a layer of resin over the object however it doesnt actually bond with the foam it relies on a mechanical linkage from overhangs and edges stopping it from being removed. However this is both expensive and not ideal, I ended up developing my own system. I knew contact cement bonded with plastazote, however it was too thick to be painted evenly over a surface. I tried mixing it with solvents to thin it out but they all (acetone, ipa, naptha, turpentine, cellulose) just seperated it. In the end the branded adhesive cleaner (contains xylene) was able to thin it out and allow painting over the surface. This allowed my next layers to adhere with no troubles. These layers consisted of slightly watered down PVA medium (used the medium as it self levells better than regular glue), originally I overcomplicated the process by using a spray gun however getting an even layer required so much it dripped excessivly, in the end the best meathod was simply brushing on the pva (more time consuming but a better result). acrylic paint was added to tint the pva and make it easy to see what piece needs more.

- 30. paint (filling and base coats) I used halfords filler primer again to give a base layer to the paint for the suit, as its an automotive paint designed for plastics it has a bit of flex to it. Aside from the obvious evening of the colour, giving a solid surface to the piece highlights any faults and gaps which would be difficult to see otherwise. These are filled with either p-38 resin filler (if im in a hurry) or “paintable-flexible gap filler” if i am not. Both work fine however the gap filler air dries and so can take a long time to cure in large thicknesses, it is however much cheaper and non toxic. After filling the gaps the surface is sanded downto prep for the base coat of paint, as its a metallic finish I used a black paint to make the metallic shade deeper.

- 32. painting (colours) The metallic silver base was done with montana sprays black range, I already liked their chrome spray from the gold range and the black range has larger cans and wider sprays for fast coverage. I was able to cover the whole suit in two coats for 12 gbp worth of paint. Next was the masking, I used a humbrol product called maskol to stop the next layer of paint affecting it. As I was doing the silver as a metallic base to look like a metal surface had been painted then the paint had flaked off i had to do another array of masking fluid after the first layer of blue paint had been applied, I also ran lines of masking tape to create patterns under the grey. The final coat was a layer of granite grey spray paint, which on its own looks comical, but with weathering created the perfect ex future army colour.

- 36. weathering (base grime) The clean suit looks almost comical, as though it had been freshly printed. Given that my suit had to be at least 80 years old, several layers of grime had to be added. I started with a black wash, slightly watering down black acrylic and in most cases covering the surface with it. Then used a dry cloth to work it into the cracks and damage, then finally a damp cloth to wipe most off using short fast strokes to preserve the grime you see above.

- 37. Of course, when metal ages (particularly in a moist envi- ronment) it rusts. To get this effect I used iron powder and a mixture of chemicals I got from the Volpinprops painting and weathering ebook. Vinegar, hydrogen per- oxide, lemon juice and salt all combined to make a very potent oxidiser. This is then sprayed over the surface in a fine mist, taking care not to let it build up too much on any one area otherwise it will run and drip down the piece. It starts acting immediately, however letting it work over- night or over a weekend heightends the effect. First slightly soapy water is painted on to the area where rust is wanted, then iron powder is dusted on and sticks to the water. Finally the spray is applied and sets the iron rusting. rust

- 38. doodads and electronics No suit is complete without tubes, wires and details that bring it to life. Most of the time i just printed and painted (sometimes adding in a mould and cold cast) before affixing them to the suit in various meathods. - The chain for the cannon is linked together with steel wire pins held in with hot glue, the shells are also held in with hot glue. Since the piece is sitting inside the cannon it just threads through and allows friction to hold it. - The tube mount on the arm has fake screws on it , but mounting it required a real mechanical bond. I drilled several holes and used superglue to secure short nails with wide heads so that they protruded out of the base. Then I added superglue to the underside and around the nails and pressed it into the suit through the layers of paint and pva. - The tube mounts on the back had to have wires running through the bases, but they were designed with a lip. A hole smaller than the lip was cut and epoxy was put around the edges, meeting with the lip when the piece was seated in.

- 39. This turbine fan was printed then spray coated, it fits very tightly into the foam shroud so it doesnt require an adhesive to stick it in. These details are actually just little blower fans that I use for my 3d printer. I managed to accidentally order 5v so when i hooked them up to my 12v printer they blew instantly. Originally I was going to have two chains hanging from each shoulder, however when i found a chain hoist in the metal workshop I realised it had exactly the look I wanted. So a quick design and 4 hours print gave me the piece used now. Of course the clearest example of this is the cannon, this was entirely printed and painted. Then attached with screws so it can be removed for transport, these attach to a bracket on the inside of the arm clamping it to the foam. The lights are simple 12v LED strips with a clear printed plastic cover, running at 9v so that they are not so bright. The tubes are simple PVC covered in webbing used for cable runs, if done again I would use silicone tube instead as its far less rigid. Connecting the cannon to the body are several tubes, for visual effect I printed pieces which split the two tubes into 4 and contain them along the way. The tubes are silicone and so have plenty of flex but are an absolute pain to stick into any piece.

- 40. Hands The hands are of my own design, parts of which can be seen throughout this book. Designed to use as many 3d printed parts as possible I was looking to make a design that I could easily adapt, after university is finished, into hands that could be adjusted and used inside a creature suit. They use elastic for the return, steel cable for the pull, 10mm square steel rod for the arm bracer and M3 machine screws for all the joints. M5 screws attach the hands to the arm brace, allowing the braces to be put on before the suit and the hands slotted on afterwards. Gloves with hooks on the end of each finger pull each string individually.