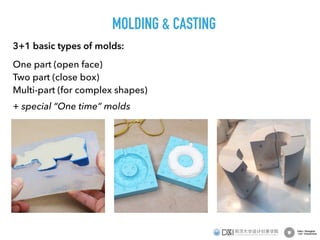

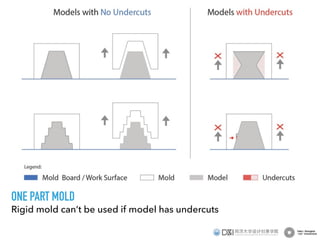

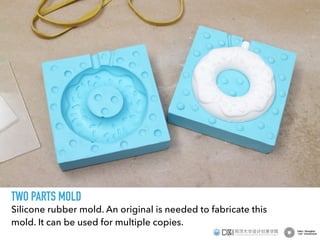

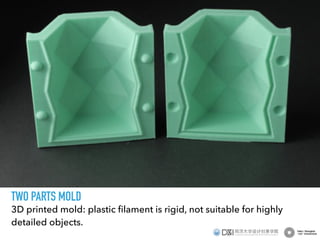

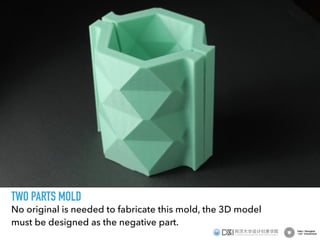

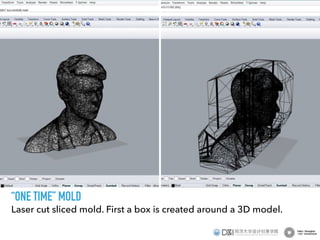

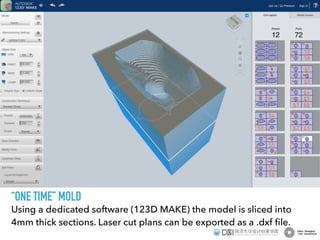

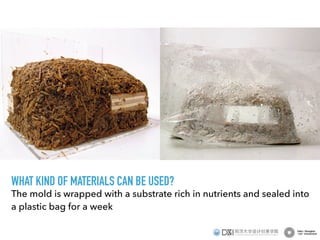

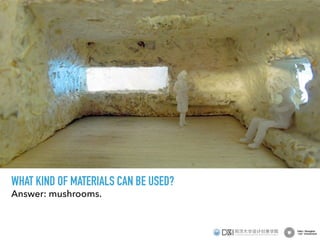

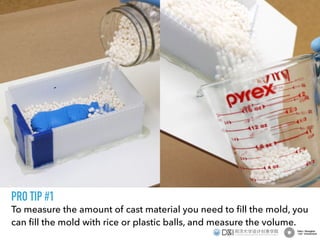

This document discusses different types of molds and casting techniques. It begins by defining molds, models, and casts. There are three basic types of molds: one-part molds with an open face, two-part close box molds, and multi-part molds for complex shapes. Additional mold types include flexible molds for undercuts and "one time" molds that are destroyed when removing the cast. The document provides examples of molds made from materials like silicone, plastic, wood, and 3D printed parts. It also discusses casting materials that can be poured or grown like mushrooms to form around a mold.