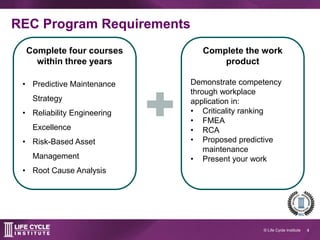

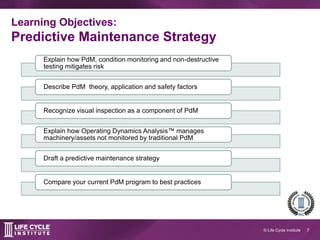

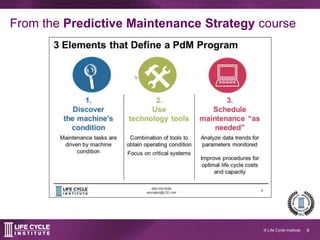

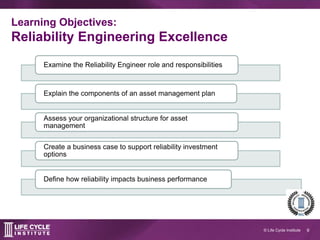

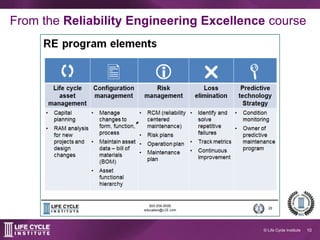

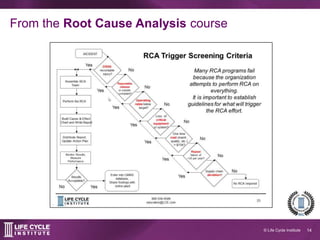

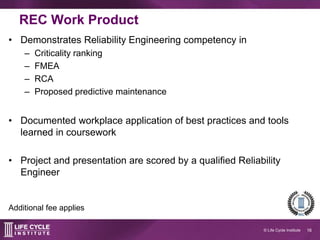

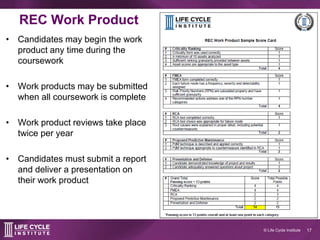

The document outlines the Reliability Engineering Certification (REC) program offered by the Life Cycle Institute, highlighting its benefits such as improving asset utilization and fostering a culture of continuous improvement. Participants must complete four courses and demonstrate their competency through a work product. The program is designed for professionals focused on enhancing asset reliability and developing sustainable predictive maintenance strategies.