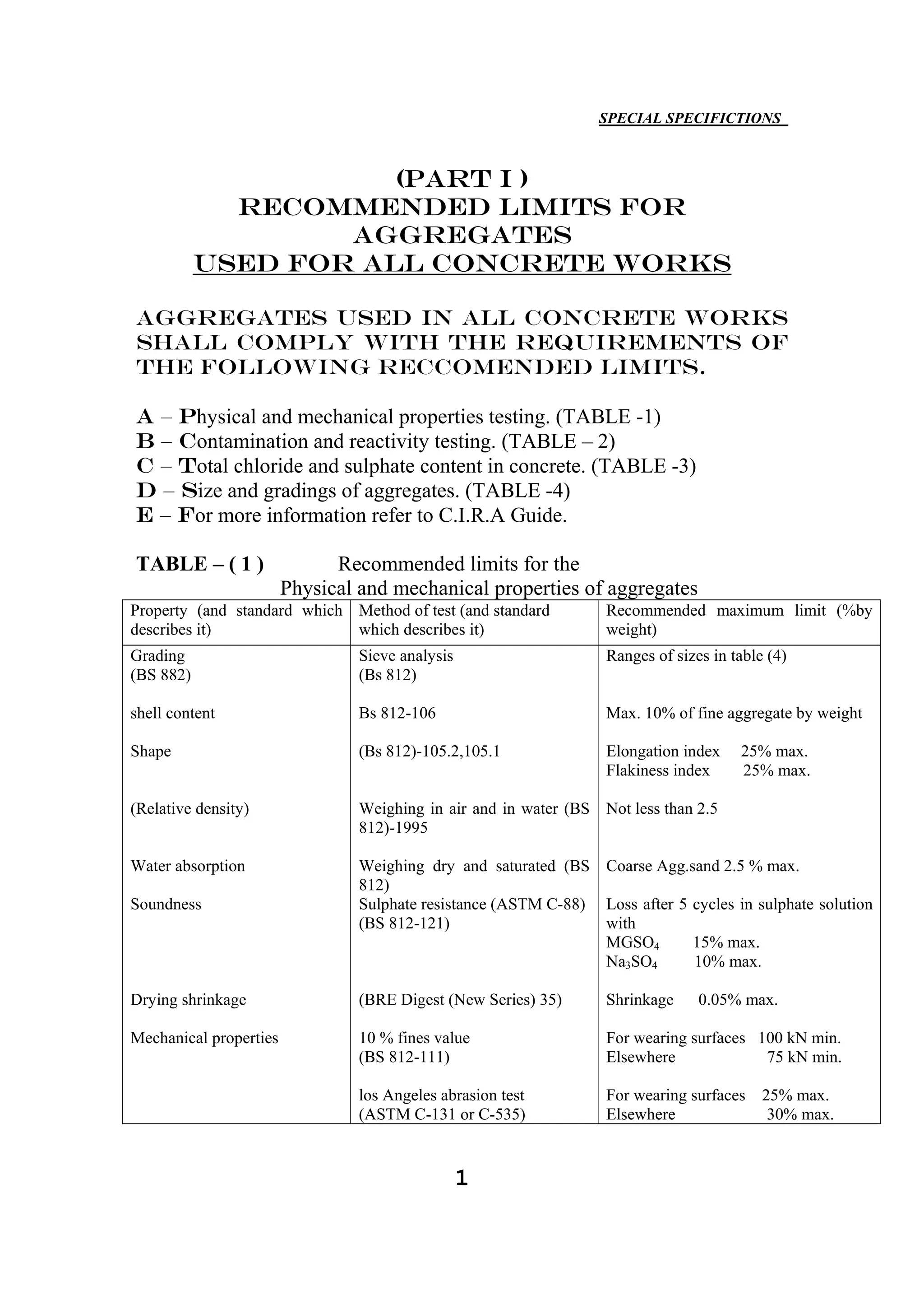

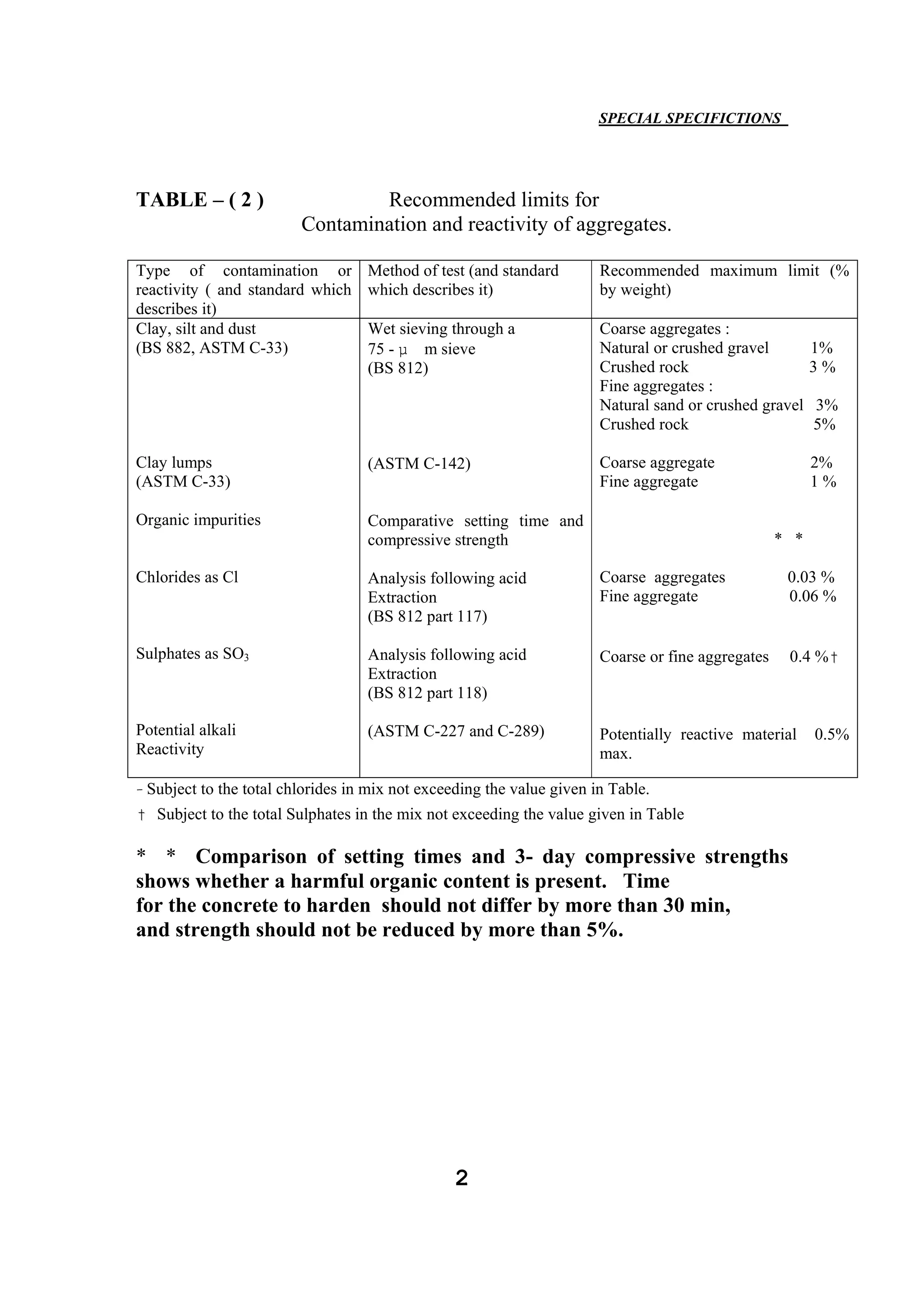

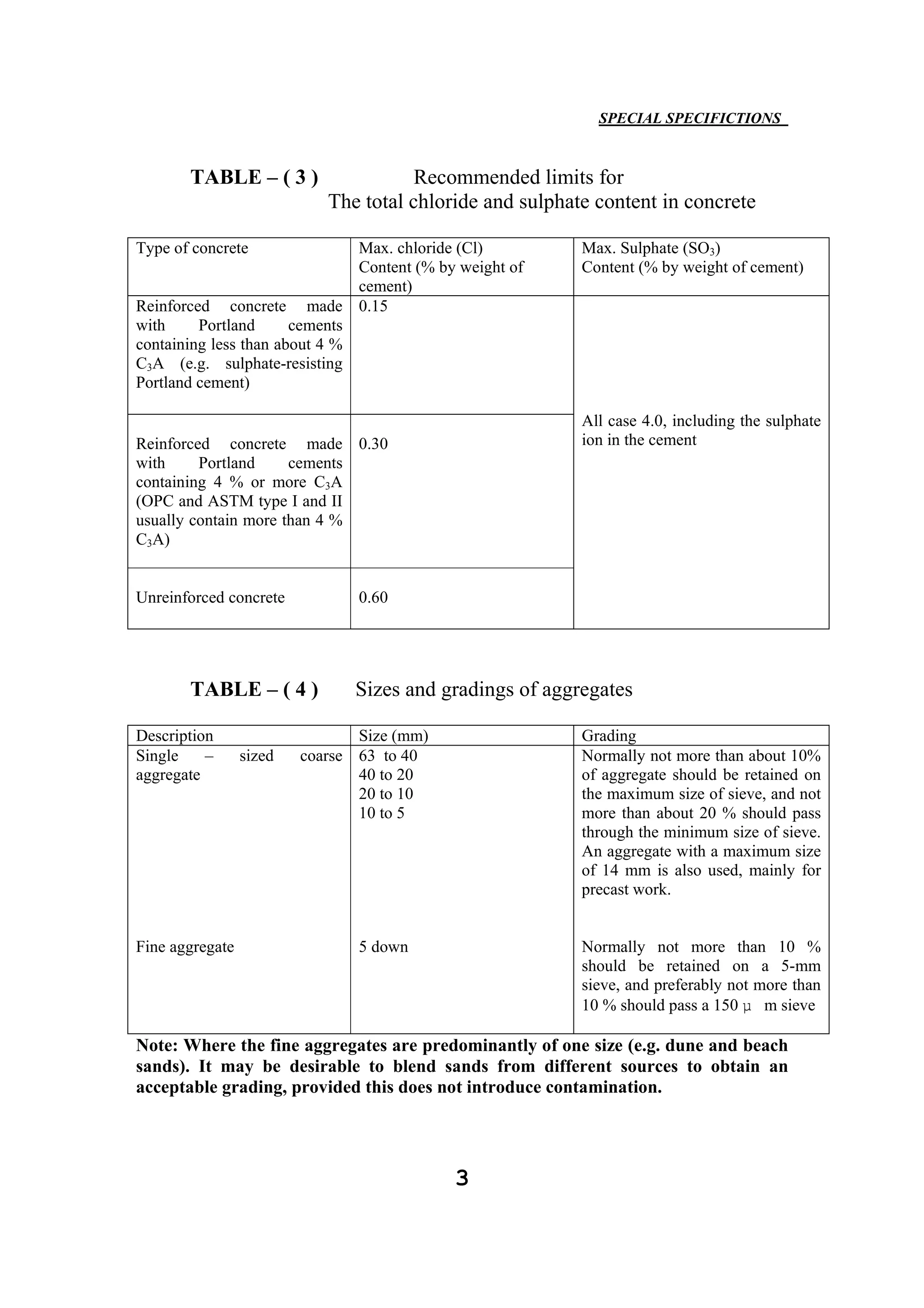

This document provides recommended limits for aggregates used in concrete works. It includes 4 tables that specify: 1) physical and mechanical properties testing of aggregates, 2) contamination and reactivity testing, 3) total chloride and sulphate content limits in concrete, and 4) recommended size and gradings of aggregates. Contractors should ensure aggregates comply with the limits in these tables to ensure quality concrete.