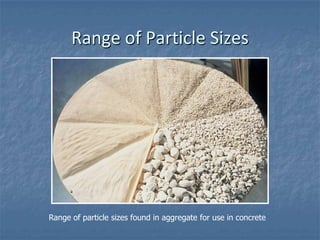

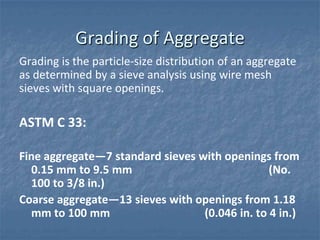

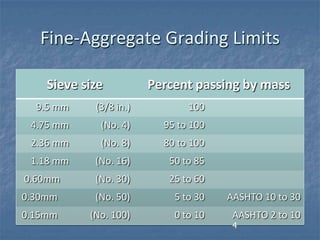

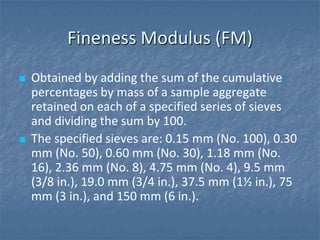

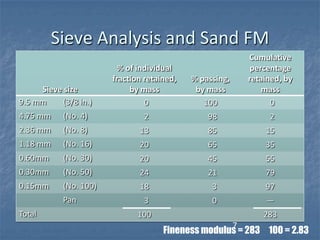

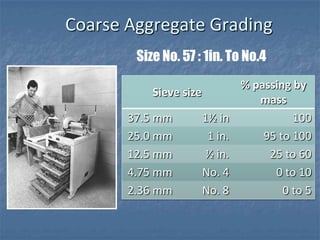

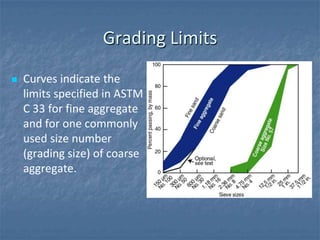

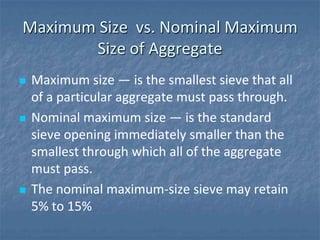

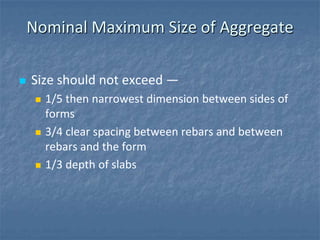

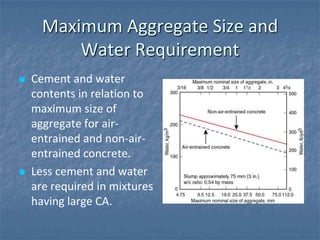

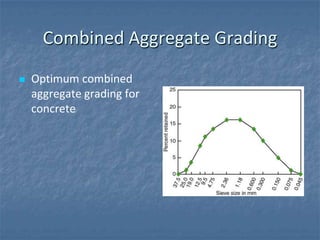

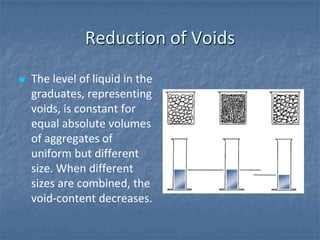

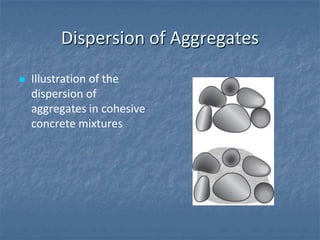

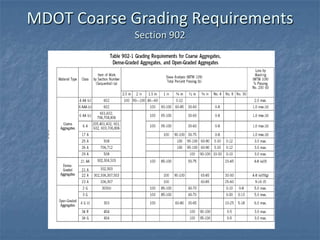

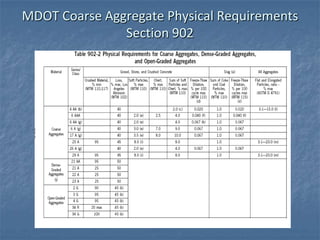

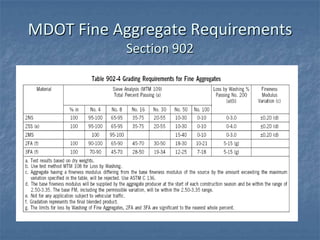

This document discusses standards and evaluation of fine and coarse concrete aggregates. It covers particle size ranges, grading requirements, fineness modulus calculations, aggregate types (normal weight, lightweight, heavyweight), maximum size versus nominal maximum size, and how aggregate selection impacts water demand and void content. Standards are provided by ASTM and state DOT specifications. Videos are recommended to further explain key topics like grading limits and void reduction.