Indian standard method for mix design M45

- 2. Design a concrete mix for M45 grade of concrete with the following data. (by IS Method) Type of Cement OPC 43 Grade Maximum Size Of Aggregate 20 mm Type of Exposure Sever (RCC) Workability 125 mm slump Minimum Cement Content 320kg/cum Specific gravity of cement 3.15 Specific gravity of coarse aggregates 2.80 Specific gravity of fine aggregates 2.70 w/c ratio 0.42 Method of placing of concrete Pumping Degree of Supervision Good Type of aggregate Crushed angular Agg. Super plasticizer will be used 20% Water Absorption Coarse Aggregate Fine Aggregate 0.5% 1% Free Surface Moisture Coarse Aggregate Fine Aggregate Nil Nil Grading of Coarse agg. Conforming to Table 2 of IS 383 (p) Grading of Fine agg. Conforming to grading zone II

- 3. 9.2.4.2 (IS 456-2000) Assumed standard deviation Where sufficient test results for a particular grade of concrete are not available. the value of standard deviation given in Table8 maybe assumed for design of mix in the first instance. As soon as the results of samples are available, actual calculated standard deviation shall be used and the mix designed properly.

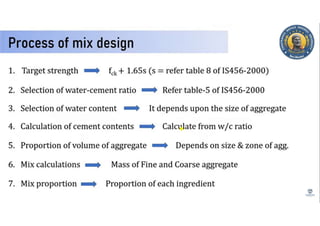

- 4. Step-1 Target Mean Strength • F’ck= fck + 1.65 s = 45 + 1.65 X 5 = 53.33 N/SQM Where F’ck- Target mean compressive strength at 28 days. fck - Characteristic Compressive strength at 28 days. s- Standard Deviation. ( Table 8, page no 23, IS 456)

- 5. Step-2 Selection Of Water Cement Ratio Clause 8.2.4.1 (IS 456-2000) The free water-cement ratio is an important factor in governing the durability of concrete and should always be the lowest value. Appropriate values for minimum cement content and the maximum free water-cement ratio are given in Table 5 for different exposure conditions. The minimum cement content and maximum water-cement ratio apply to 20mmnominal maximum size aggregate. For other sizes of aggregate they should be changed given in Table6.(IS 456 )

- 7. • For Severe Exposure (RCC) and maximum nominal size of aggregate 20 mm. As per IS Water Cement ratio is 0.45 Adopted W/c Ratio is 0.42 < 0.45 Hence, Its Ok.

- 8. Step-3 Selection of Water Content • Clause 4.2 (IS 10262-2009) The water content of concrete is influenced by a number of factors, such as aggregate size, aggregate shape, aggregate texture, workability, water-cement ratio, cement and other supplementary cementitious material type and content, chemical admixture and environmental conditions. An increase in aggregates size, a reduction in water- cement ratio and slump, and use of rounded aggregate and water reducing admixtures will reduce the water demand. On the other hand increased temperature, cement content, slump, water-cement ratio, aggregate angularity and a decrease in the proportion of the coarse aggregate to fine aggregate will increase water demand

- 9. Clause 4.2 (IS 10262-2009)- The quantity of maximum mixing water per unit volume of concrete may be determined from Table 2.(IS 10262-2009) The water content in Table 2 is for angular coarse aggregate and for 25 to 50 mm slump range. The water estimate in Table 2 can be reduced by approximately 10 kg for sub-angular aggregates, 20 kg for gravel with some crushed particles and 25 kg for rounded gravel to produce same workability. For the desired workability (other than 25 to 50 mm slump range), the required water content may be established by trial or an increase by about 3 percent for every additional 25 mm slump or alternatively by use of chemical admixtures conforming to IS 9103. This illustrates the need for trial batch testing of local materials as each aggregate source is different and can influence concrete properties differently. Water reducing admixtures or super plasticizing admixtures usually decrease water content by 5 to 10 percent and 20 percent and above respectively at appropriate dosages.

- 11. From Table-2.(IS 10262-2009) Maximum water content is 186 liters. This is for 50 mm slump. Estimated water content for 125 mm slump (3% increase for every 25 mm slump and above 50 mm slump, There fore total increase in water content is by 9%)= 186 + ( 186x 9/100) = 203 liter. It is given that super plasticizer used as 20%. Therefore actual water to be used = 203 x 0.80 = 162 Liter.

- 12. Step-4 Calculation Of Cement Content Water Cement Ratio= Water Content/Cement Content. Water Cement Ratio – 0.42 Water Content - 162 liters Cement Content = Water Content/ Water Cement Ratio = 162/0.42 = 385.70 kg/cum This cement content checked against minimum cement content mentioned in Table No. 5 of IS 456 for Durability requirement. The minimum cement content mentioned in Table 5 is 320 kg/cum for mild exposure there fore calculated cement content is more, so Its ok.

- 14. Step-5 Calculation of Coarse and Fine Aggregates. • • Clause 4.4.(IS 10262-2009) Estimation of Coarse Aggregate- Proportion Aggregates of essentially the same nominal maximum size, type and grading will produce concrete of satisfactory workability when a given volume of coarse aggregate per unit volume of total aggregate is used . Approximate values for this aggregate volume are given in Table 3 for a water-cement ratio of 0.5, which may be suitably adjusted for other water cement ratios . It can be seen that for equal workability, the volume of coarse aggregate in a unit volume of concrete is dependent only on its nominal maximum size and grading zone of fine aggregate. Differences in the amount of mortar required for workability with different aggregates, due to differences in particle shape and grading, are compensated for automatically by differences in roadded void content.

- 16. As per Clause 4.4.(IS 10262-2009) Volume of coarse aggregate corresponding to 20 mm size aggregate and fine aggregate zone II, for w/c ratio found out to be 0.62. In the present case w/c ratio is 0.42 i.e. it is less by 0.08. As the w/c reduced it is desirable to increase the coarse aggregate proportion to reduce the fine aggregate content. The coarse aggregate is increased at the rate of 0.01 for every decrease in w/c ratio of 0.05. :. (0.01/0.05) x 0.08= 0.016 There For correct volume of CA = 0.62+0.016 = 0.636 For Pumpable Concrete coarse aggregate can be reduced by 10%. :. Volume of CA = 0.636 x 0.90 = 0.57 :. Volume of FA = 1-0.57 = 0.43

- 17. Step-6 Calculation Of Mix Proportions. Assume Volume of Concrete = 1 CUM -------(A) Volume Of Cement = = = 0.122 CUM ------(B) Volume of water = = = 0.162 CUM ------(C) Volume of all Aggregates = A- ( B + C) = 1- ( 0.122 + 0.162)= 0.716 CUM ----(D)

- 18. Mass of Coarse Aggregates = D x Sp. Gravity CA x Volume of CA x 1000 = 0.716 x 2.7 x 0.57 x 1000 = 1024.5 kg Mass of Fine Aggregates = D x Sp. Gravity FA x Volume of FA x 1000 = 0.716 x 2.65 x 0.43 x 1000 = 891.77 kg

- 19. Step-7 Mix Proportion Cement = 385.75 kg Fine Agg.= 891.77 kg Coarse Agg= 1024.5 kg Cement = 1 Therefore Mix Proportion for M45 Concrete FA = = 2.31 1 : 2.31 : 2.65 CA = = 2.65