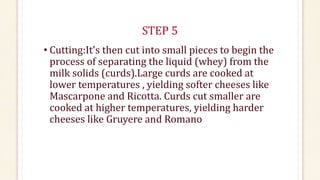

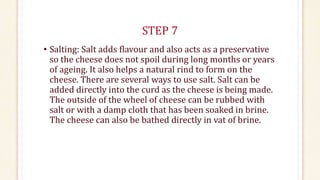

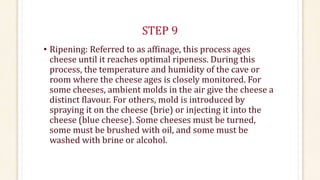

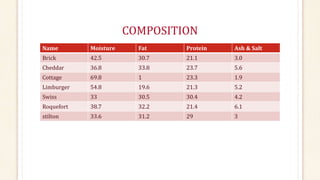

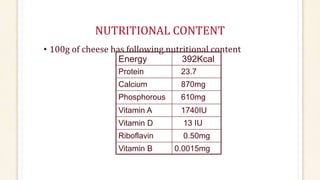

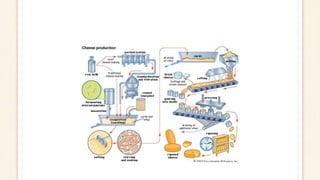

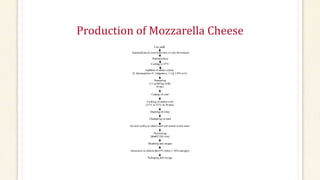

The document provides a detailed overview of cheese production, from the coagulation of milk proteins to the aging process. It outlines the steps involved, including milk preparation, acidification, coagulation with rennet, curd cutting, salting, and ripening. Additionally, it includes nutritional content and classifications of various cheese types.