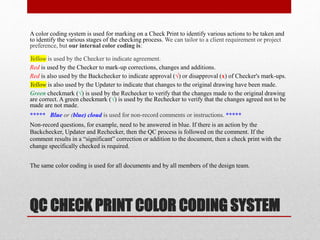

This document outlines the quality management plan requirements for large design-build transportation projects. It explains that a project quality management plan is a contract requirement and must be tailored to each specific project. It describes the different levels of quality control checks that will be performed at both the company and project levels, including detail checking, constructability reviews, cross-disciplinary reviews, and technical reviews. Appendices will include design control procedures, forms, deliverable lists, and the plan must be ISO and FTA compliant. The roles and responsibilities of all parties in the quality control process are defined, along with color-coding systems used for markups and revisions. Quality assurance audits will also be performed to ensure the quality management plan is followed.