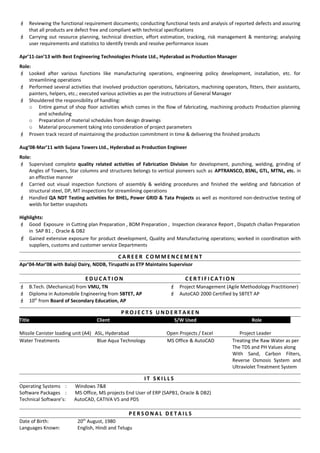

The document contains a resume for P. RAGHU summarizing his professional experience and qualifications. He has over 10 years of experience in project production operations and has been commended for his performance. He has extensive experience managing projects, production operations, quality control and ensuring compliance. He is proficient in various engineering software and codes/standards. His most recent role was as Project Manager at TA Hydraulics Private Ltd since 2013 where he was responsible for resource planning and technical direction.