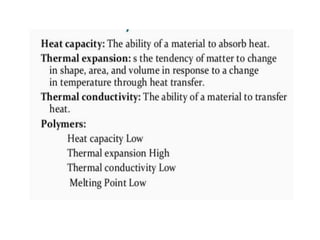

The document discusses various thermal properties of textile materials including thermal conductivity, glass transition temperature, melting temperature, thermal expansion, and heat setting. Thermal conductivity refers to the rate of heat transfer through a material. Glass transition temperature is the temperature at which a material changes from hard and glass-like to soft and rubbery. Melting temperature is when a material melts and loses its strength and identity. Thermal expansion is the increase in length of a material from rising temperatures. Heat setting is a process that stabilizes the form and size of a material through drying and cooling cycles.