This document provides technical specifications and details for various pulley products, including:

1. An overview of Superior's product range including CEMA, mine duty, super duty, and Chevron wing pulleys in various duty classes.

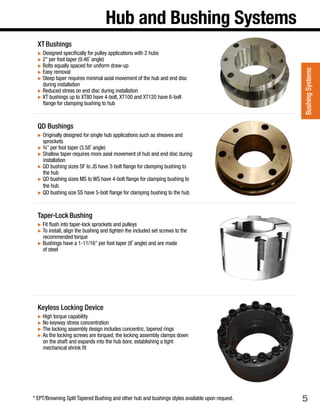

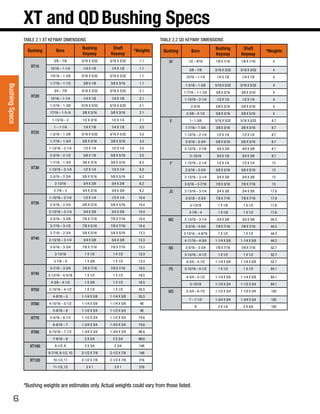

2. Dimensions for XT and QD bushing systems used with pulleys.

3. Tables and figures with pulley specifications such as bushing locations, pulley assemblies, pulley classes, pulley drawings, torque values, weights, formulas, and other technical information.

The document serves as a reference guide for pulley specifications, components, and technical details. It includes specifications for different pulley types, duty classes, components, and formulas.

![11

E-ClassData

Drive Pulley Shaft Detail Worksheet

Pulley Identification_ ____________________________________

Belt Width____________________________________________

Pulley Diameter Dimension OD____________________________

Pulley Face Width Dimension FW___________________________

Crown Face or Flat Face__________________________________

Hub Type_____________________________________________

Lagging Thickness & Type_________________________________

Drive Side (Right or Left)__________________________________

[Standing at Tail Looking to Head]

Pulley Offset Dimension O________________________________

Number of Keyseats_____________________________________

Pulley Keyseat Size_____________________________________

Shaft Material_ ________________________________________

Major Shaft Diameter Dimension D_________________________

Overall Shaft Length Dimension OAL________________________

Shaft Diameter at Hubs___________________________________

Shaft Diameter at Bearings________________________________

Shaft Diameter at Reducer Dimension R______________________

Drive Key Size x Length Dimension DK_______________________

Reducer Journal Length Dimension JL_______________________

Shaft Diameter at Backstop Dimension B_____________________

Key Size x Length Dimension BK_ __________________________

Bearing Centers Dimension BC____________________________

Bearing Type__________________________________________

Shaft Drill and Tap (Size & Qty)_ ____________________________

JL

D

O

DK

OD

FW

RB

BK

OAL

BC

Components Division

P.O. Box 654

Highway 28 East

Morris, MN 56267

DATEDRAWN BY ASSEMBLY NO.

DRAWING NUMBER REV

2d pulley

FILE

SCALE (UNO) CHECKED SIZE

B

THIS DRAWING IS THE PROPERTY

OF SUPERIOR INDUSTRIES. IT IS

NOT TO BE REPRODUCED IN ANY

MANNER WITHOUT PERMISSION.

ALL DIMENSIONS IN INCHES (UNO)

TOLERANCES UNLESS

OTHERWISE NOTED:

FRACTIONAL: 1/32

ANGULAR: .1

DECIMAL: 0.0 .1

0.00 .05

0.000 .005

0.0000 .0020

HOLE : 1/32

SYTELINE PART NO.WEIGHT

MATERIAL

NTSFORMAT

SOLIDWORKS

THIRD

ANGLE

PROJECTION

Non-Drive Pulley Assembly Details

Pulley Identification____________________________________

Belt Width____________________________________________

Drum Pulley or Wing Pulley________________________________

Pulley Diameter Dimension OD____________________________

Pulley Face Width Dimension FW___________________________

Crown Face or Flat Face _________________________________

Hub Type_____________________________________________

Lagging Thickness and Type_______________________________

Pulley Offset Dimension O________________________________

Shaft Material_ ________________________________________

Major Shaft Diameter Dimension D_________________________

Overall Shaft Length Dimension OAL________________________

Number of Keyseats_____________________________________

Keyseat Size__________________________________________

Shaft Material_ ________________________________________

Shaft Diameter at Hubs___________________________________

Shaft Diameter at Bearings________________________________

Shaft Diameter on Ends (if stub shaft)_ _______________________

Bearing Centers Dimension BC____________________________

Bearing Type__________________________________________

Shaft Drill and Tap (Size & Qty)_ ____________________________

OAL

DOD

FW O

BC

Components Division

P.O. Box 654

Highway 28 East

Morris, MN 56267

DATEDRAWN BY ASSEMBLY NO.

DRAWING NUMBER REV

2d.idler puleey

FILE

SCALE (UNO) CHECKED SIZE

B

THIS DRAWING IS THE PROPERTY

OF SUPERIOR INDUSTRIES. IT IS

NOT TO BE REPRODUCED IN ANY

MANNER WITHOUT PERMISSION.

ALL DIMENSIONS IN INCHES (UNO)

TOLERANCES UNLESS

OTHERWISE NOTED:

FRACTIONAL: 1/32

ANGULAR: .1

DECIMAL: 0.0 .1

0.00 .05

0.000 .005

0.0000 .0020

HOLE : 1/32

SYTELINE PART NO.WEIGHT

MATERIAL

NTSFORMAT

SOLIDWORKS

THIRD

ANGLE

PROJECTION

Figure 2.2

Figure 2.1](https://image.slidesharecdn.com/pulley-catalog-11-05-low-180629052109/85/Pulley-catalog-11-05-low-11-320.jpg)

![A-33

Lagging Weights

Weight Information – Vulcanized Rubber Lagging Weights

Chart continued...

DIA. LAGGING THICKNESS

WEIGHTS / FACE WIDTH (INCHES)

10 12 14 16 18 20 22 24 26 30 32

6"

1/4

3/8

1/2

3

4

5

3

5

6

4

6

8

4

7

9

5

7

10

6

8

11

7

9

12

7

10

14

8

11

15

10

13

17

10

14

19

8"

1/4

3/8

1/2

4

5

7

4

6

8

5

7

10

6

9

11

7

10

13

8

11

14

9

12

16

10

14

18

11

15

19

13

18

23

14

19

25

10"

1/4

3/8

1/2

4

6

8

5

8

10

6

9

12

7

11

14

8

12

16

10

14

18

11

15

20

12

17

22

13

18

24

16

22

28

17

23

30

12"

1/4

3/8

1/2

5

8

10

6

9

12

8

11

14

9

13

17

10

14

19

11

16

21

13

18

26

14

20

26

16

22

28

19

26

33

20

28

36

14"

1/4

3/8

1/2

6

9

12

7

11

14

9

13

17

10

15

19

12

17

22

13

19

25

15

21

27

16

23

30

18

25

33

22

30

39

23

32

42

16"

1/4

3/8

1/2

7

10

13

8

12

16

10

14

19

12

17

22

13

19

25

15

21

28

17

24

31

19

26

34

21

29

37

25

34

44

27

37

47

18"

1/4

3/8

1/2

8

11

15

9

14

18

11

16

21

13

19

25

15

21

28

17

24

31

19

27

35

21

30

38

23

33

42

28

38

49

30

44

53

20"

1/4

3/8

1/2

9

13

17

10

15

20

12

18

24

15

21

27

17

24

31

19

27

35

21

30

39

23

33

43

26

36

46

31

43

55

33

46

59

24"

1/4

3/8

1/2

10

15

20

13

18

24

15

22

29

17

25

33

20

28

37

22

32

42

25

36

46

28

40

51

31

43

56

37

51

65

40

55

70

30"

1/4

3/8

1/2

13

19

25

16

23

30

19

27

35

22

31

41

25

35

46

28

40

52

31

44

57

35

49

63

38

54

69

46

63

81

50

68

87

36"

1/4

3/8

1/2

15

22

29

19

27

36

22

32

42

26

37

49

28

42

55

34

48

62

38

53

69

42

59

76

46

64

83

55

76

97

59

82

105

DIA. LAGGING THICKNESS

WEIGHTS / FACE WIDTH (INCHES)

36 38 40 44 46 51 54 57 60 63 66

6"

1/4

3/8

1/2

12

17

22

13

18

23

14

19

24

16

21

27

17

23

29

19

26

33

21

28

35

22

30

38

24

32

40

26

34

43

27

36

45

8"

1/4

3/8

1/2

16

22

28

17

23

30

18

25

32

21

28

36

22

30

38

25

34

43

27

36

46

29

39

49

31

42

52

34

44

55

36

47

59

10"

1/4

3/8

1/2

20

27

35

21

29

37

22

31

39

25

35

44

27

37

46

31

42

52

34

45

56

36

48

60

39

51

64

42

55

68

44

58

72

12"

1/4

3/8

1/2

23

32

41

25

34

44

27

37

47

30

41

52

32

44

55

37

50

62

40

53

67

43

57

72

46

61

76

50

65

81

53

69

86

14"

1/4

3/8

1/2

27

37

48

29

40

51

31

42

54

35

48

60

37

50

64

43

57

72

46

62

77

50

66

83

54

71

88

58

76

94

61

80

100

16"

1/4

3/8

1/2

31

43

54

33

45

58

35

48

61

40

54

69

43

57

73

49

65

82

53

70

88

57

75

94

61

81

100

66

86

107

70

91

113

18"

1/4

3/8

1/2

35

48

61

37

51

65

40

54

69

45

61

77

48

64

81

55

73

92

59

79

99

64

85

105

69

90

112

73

96

119

78

102

127

20"

1/4

3/8

1/2

39

53

67

41

56

72

44

60

76

50

68

85

53

71

90

61

81

102

66

87

110

71

94

117

76

100

124

81

107

132

87

113

140

24"

1/4

3/8

1/2

46

63

80

49

67

86

53

72

91

60

81

102

63

85

107

73

97

122

79

104

130

85

112

140

91

120

149

97

128

158

104

136

167

30"

1/4

3/8

1/2

57

79

100

62

84

107

66

90

113

75

101

127

79

106

134

91

121

151

98

130

162

106

140

174

113

149

185

121

159

196

130

169

208

36"

1/4

3/8

1/2

69

94

118

74

101

128

79

107

135

89

120

152

95

127

160

109

145

181

118

156

194

127

167

207

136

178

221

145

190

235

155

202

249

LaggingWeights

If grooved pulley (for 3/8” or 1/2” thickness) - take weight in chart and [Multiply by 0.95]

Table 10.1 Crowned Drum](https://image.slidesharecdn.com/pulley-catalog-11-05-low-180629052109/85/Pulley-catalog-11-05-low-33-320.jpg)