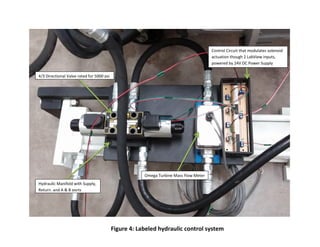

A hydraulic system was developed to actuate a cylinder forwards and backwards using an electronic valve. The system includes a directional valve, pressure transducer, and flow meter connected to a computer interface. It allows monitoring and controlling the cylinder's position. The interface displays pressure, flow rate, and includes controls to move the cylinder or return it to neutral. This provides a test system for developing feedback control of hydraulic cylinders.