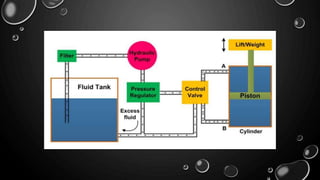

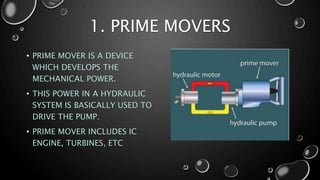

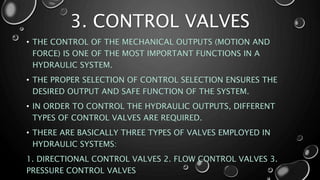

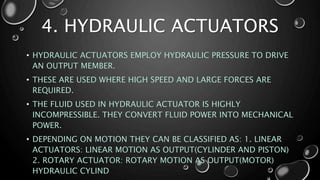

This document provides an overview of hydraulic control systems. It describes how hydraulic systems work using pressurized liquids and components like pumps, valves, actuators and filters to generate and control motion. It explains key hydraulic principles like Pascal's law and lists common applications in industries like manufacturing, construction, automobiles and aerospace. The major components of a hydraulic system are described in detail including pumps, control valves, actuators and hydraulic fluids.