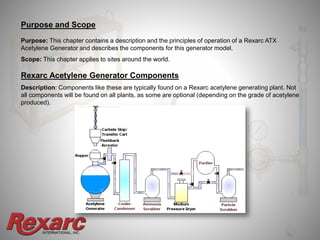

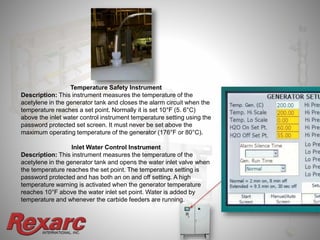

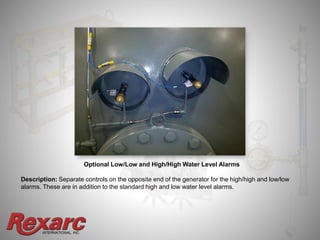

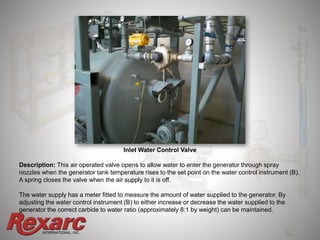

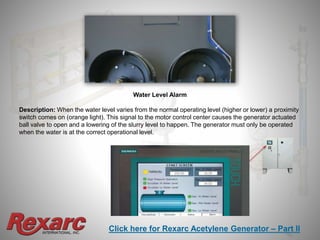

Rexarc has been a leader in industrial gas distribution systems since 1924, particularly focusing on acetylene generators. The document describes the components and principles of operation for Rexarc ATX acetylene generators, detailing how they facilitate the controlled reaction of calcium carbide and water to produce acetylene gas. It covers various operational controls, safety instruments, and required alarms for maintaining safe and efficient production processes.