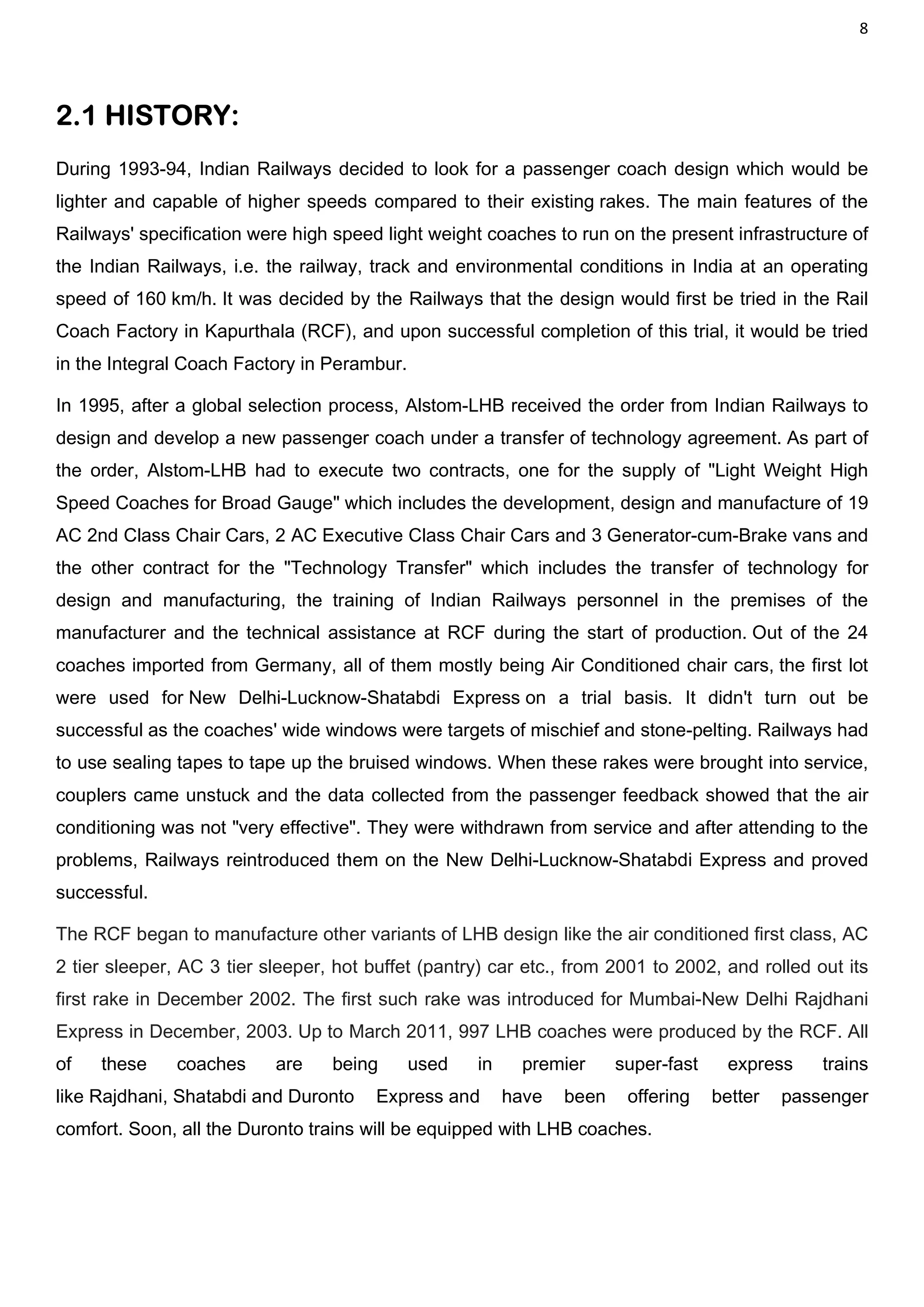

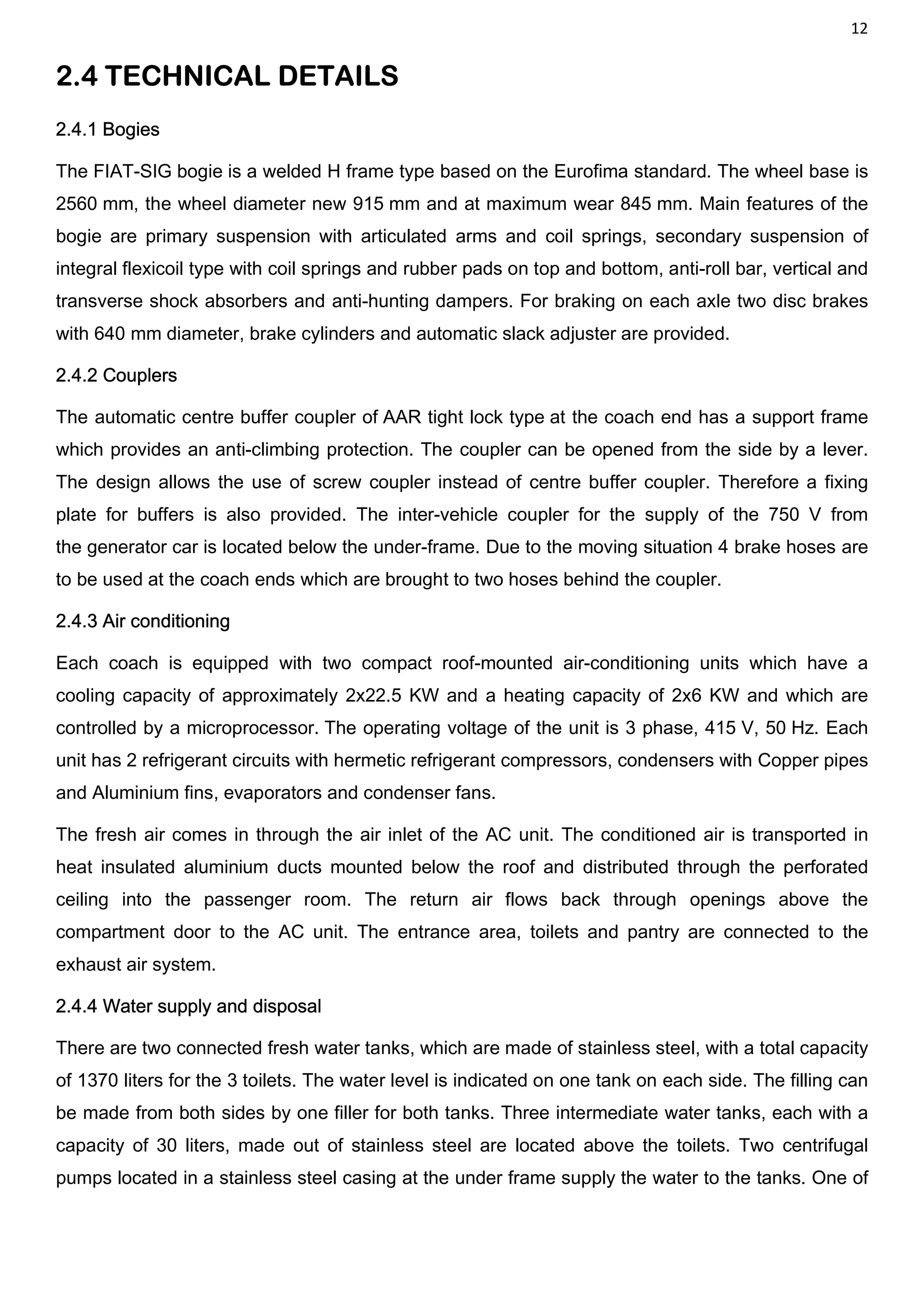

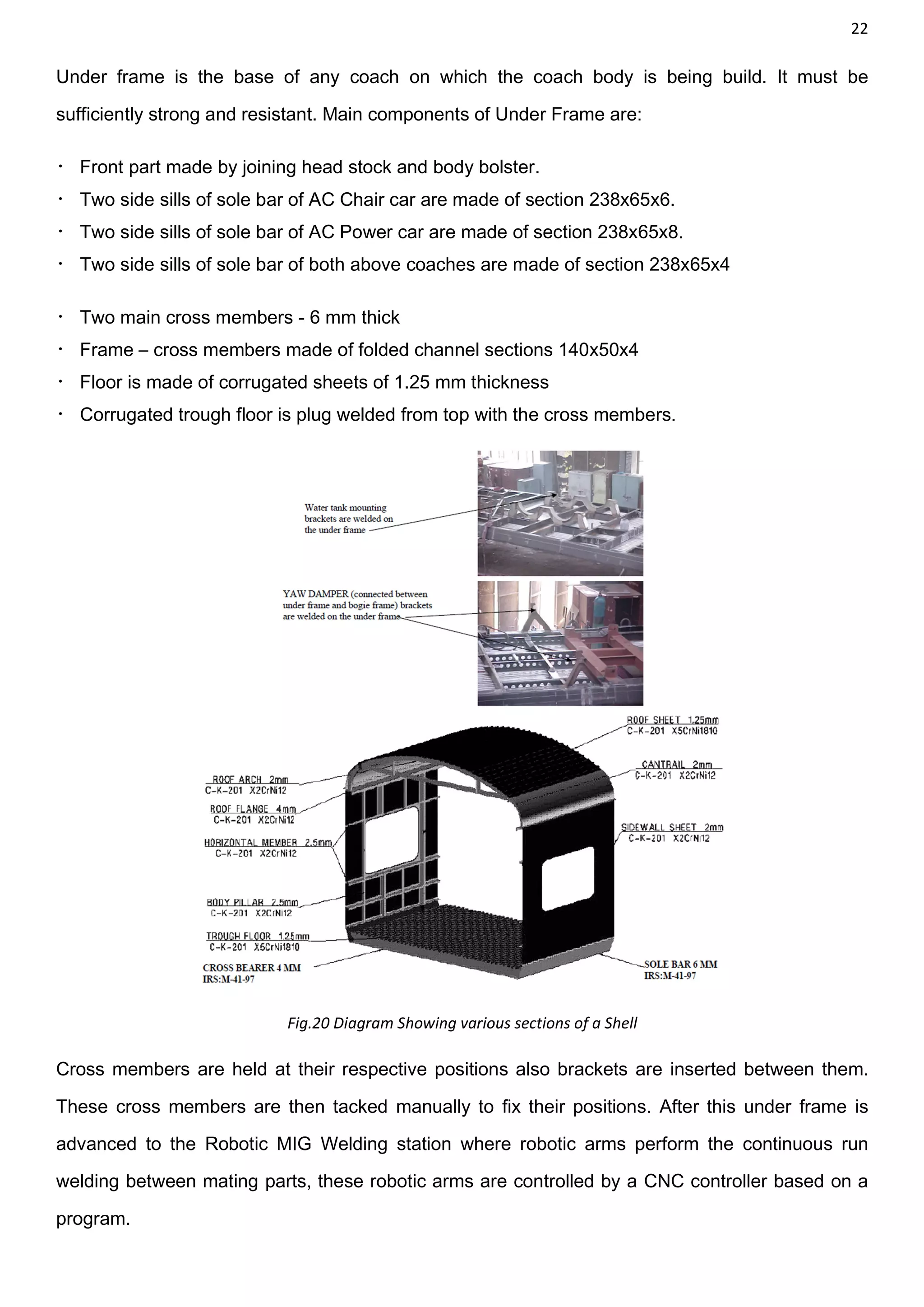

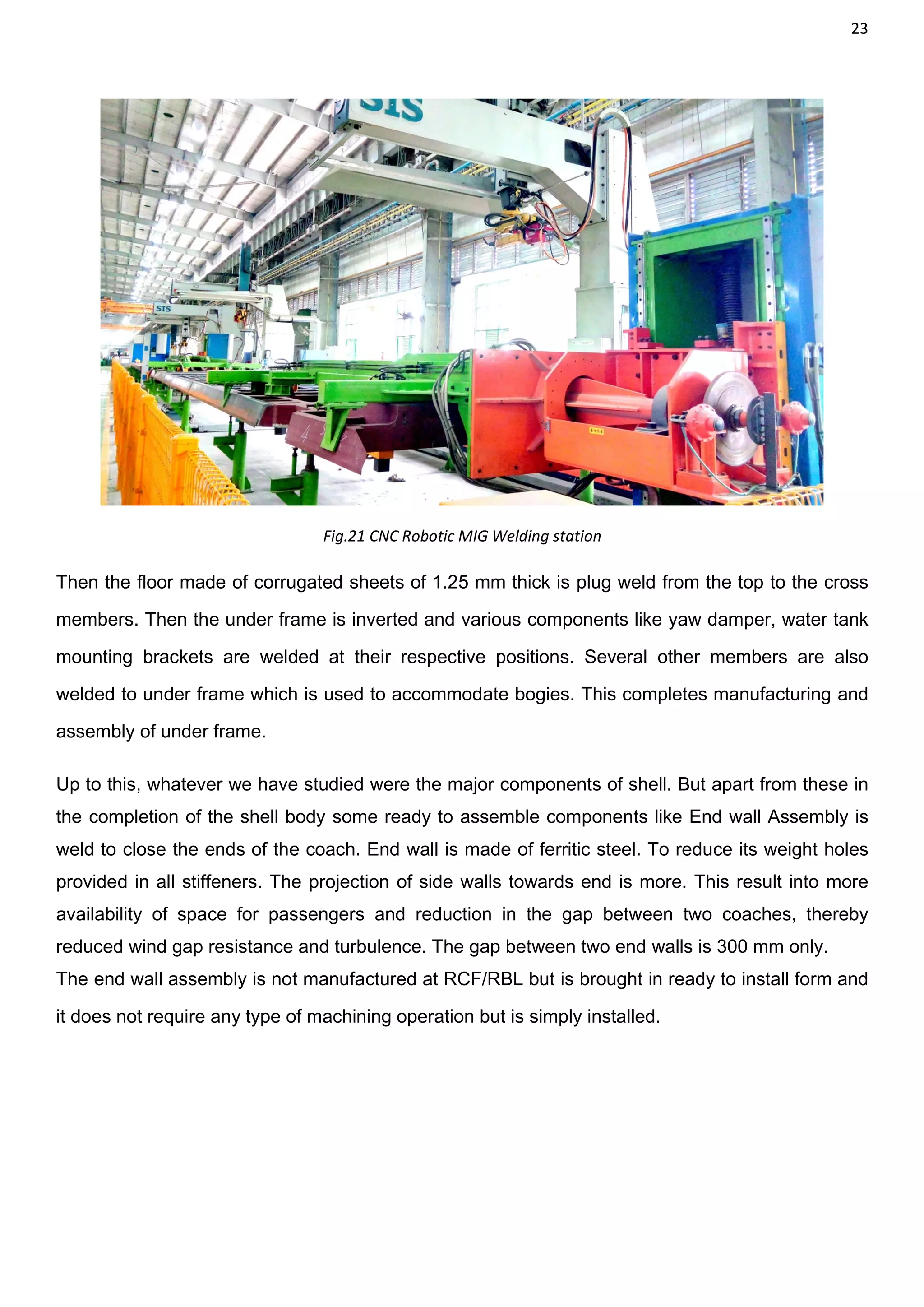

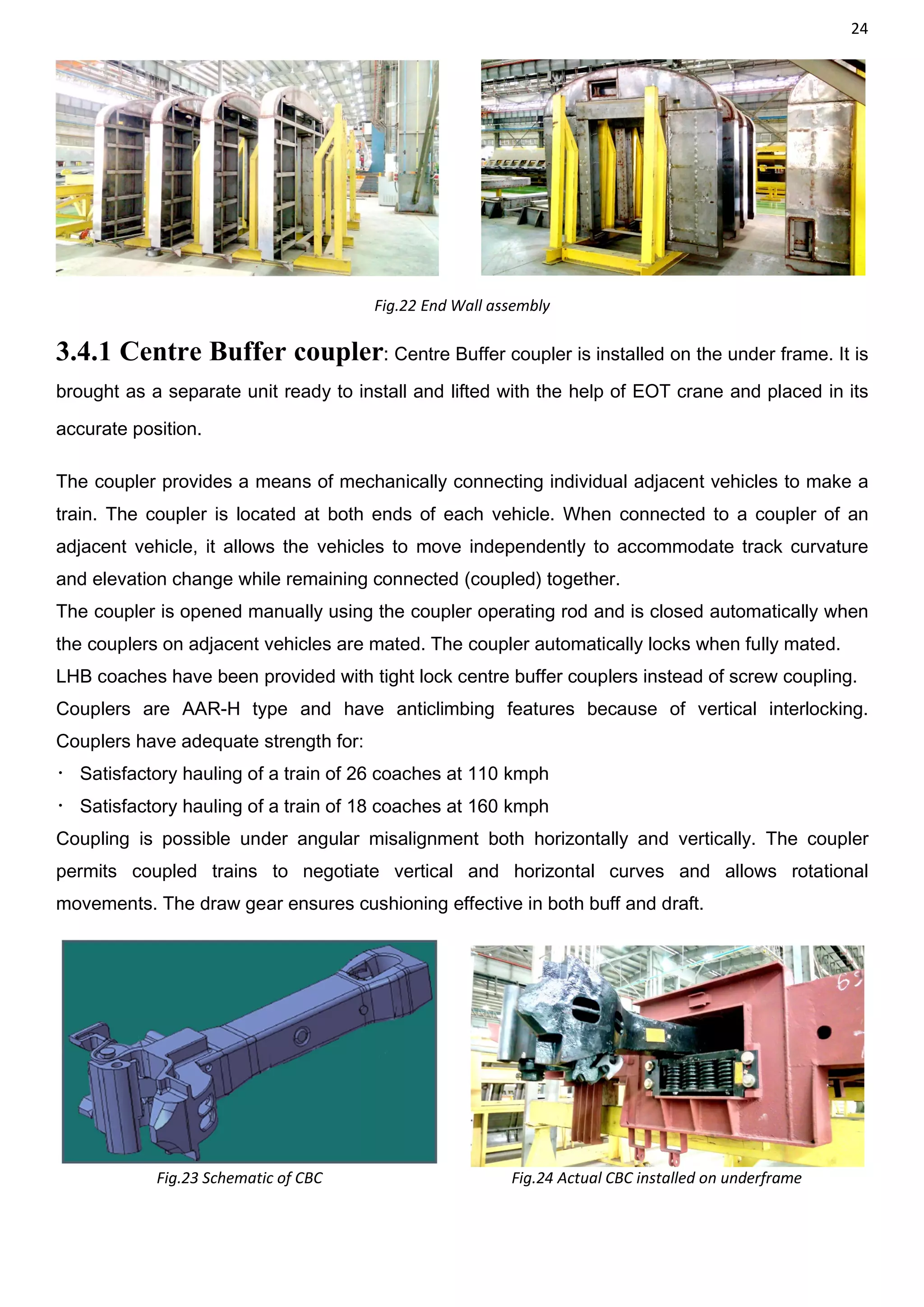

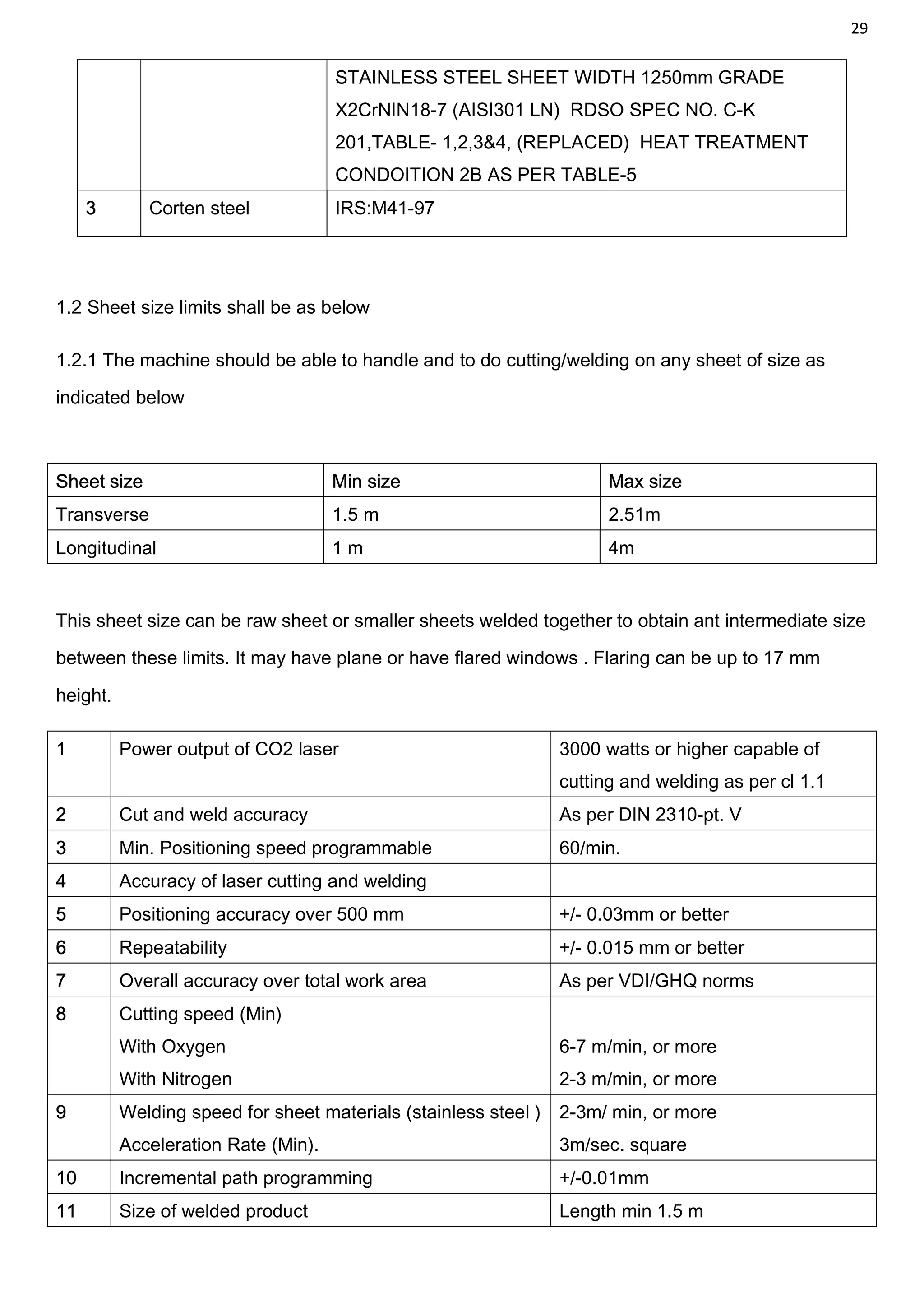

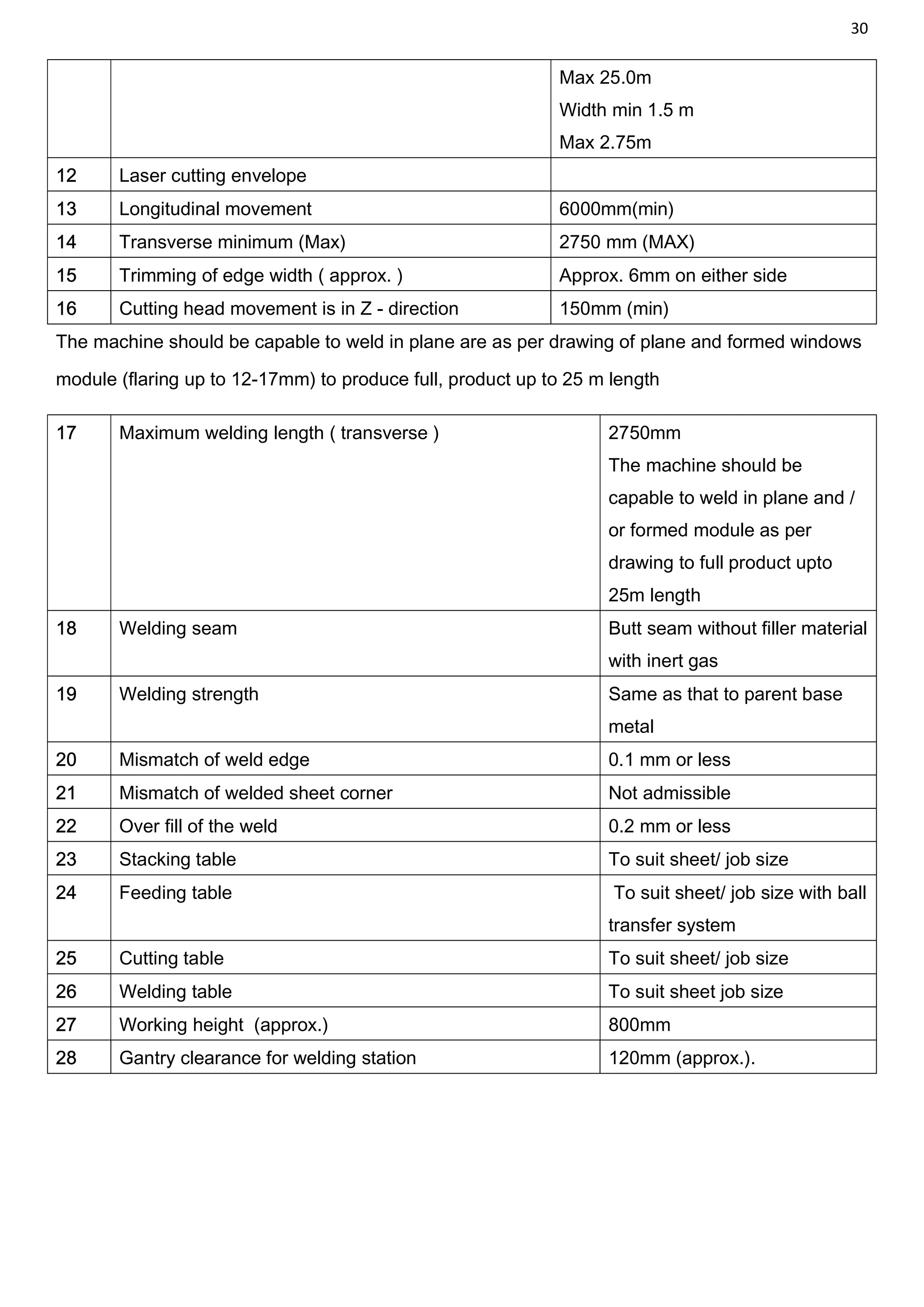

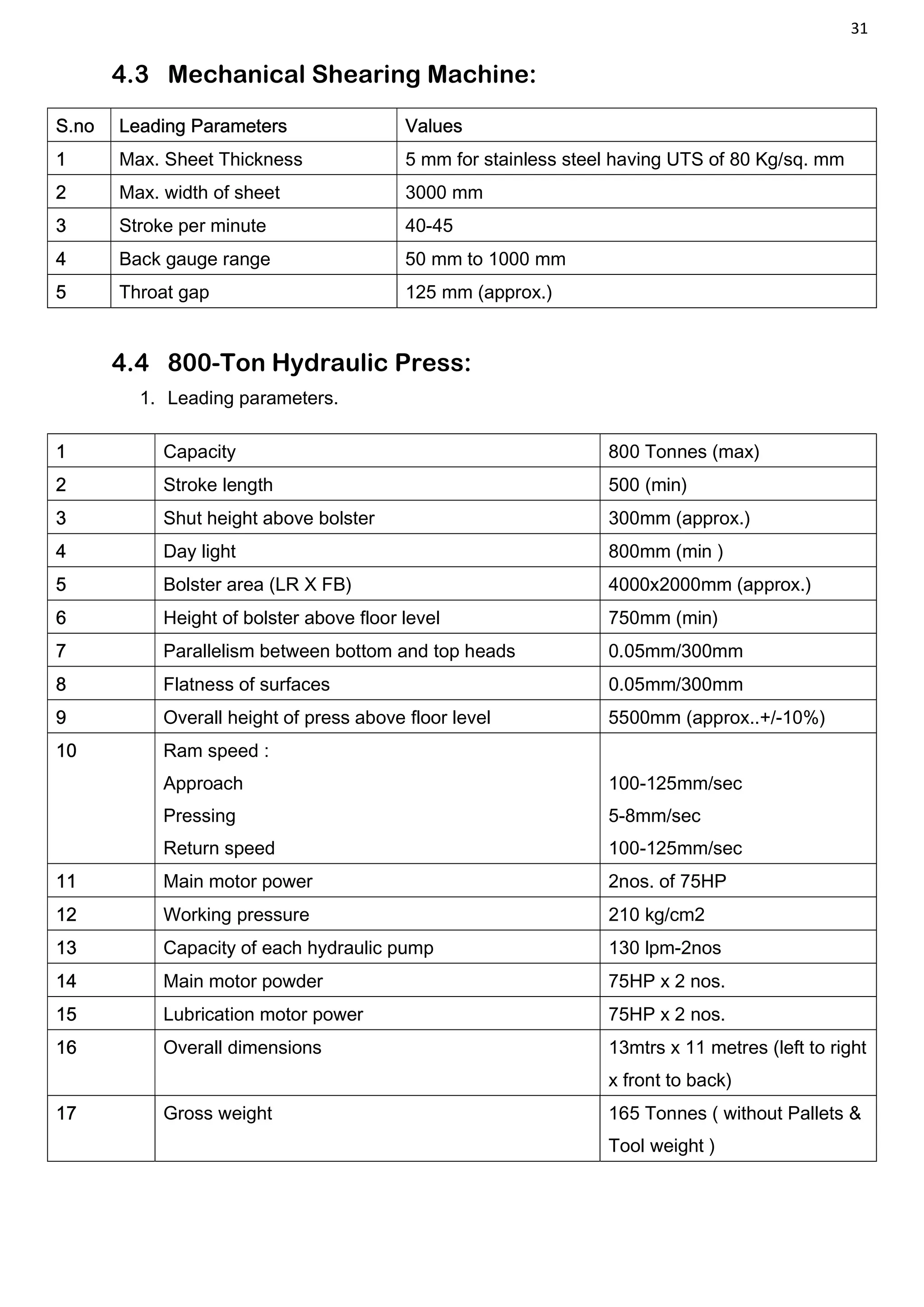

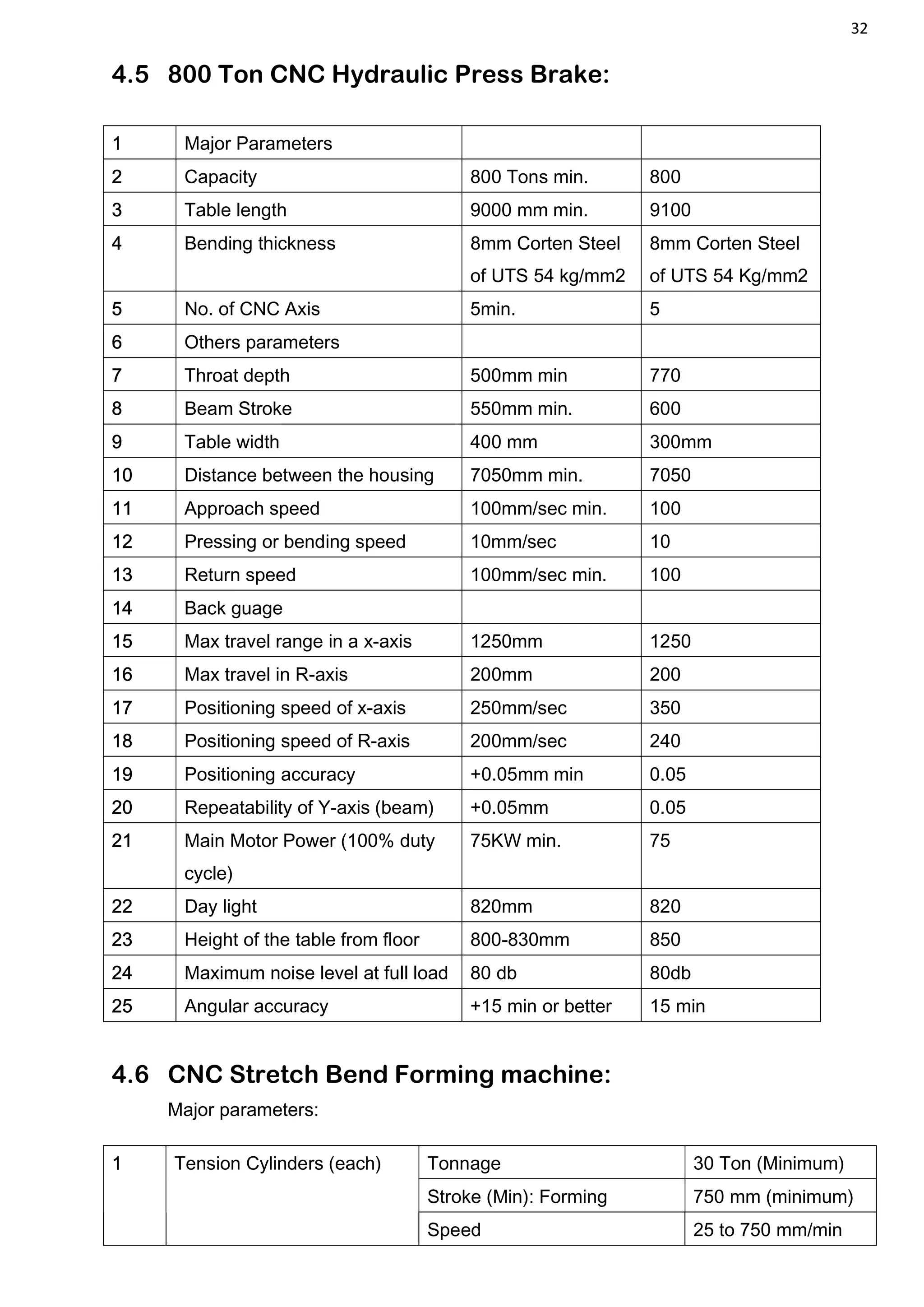

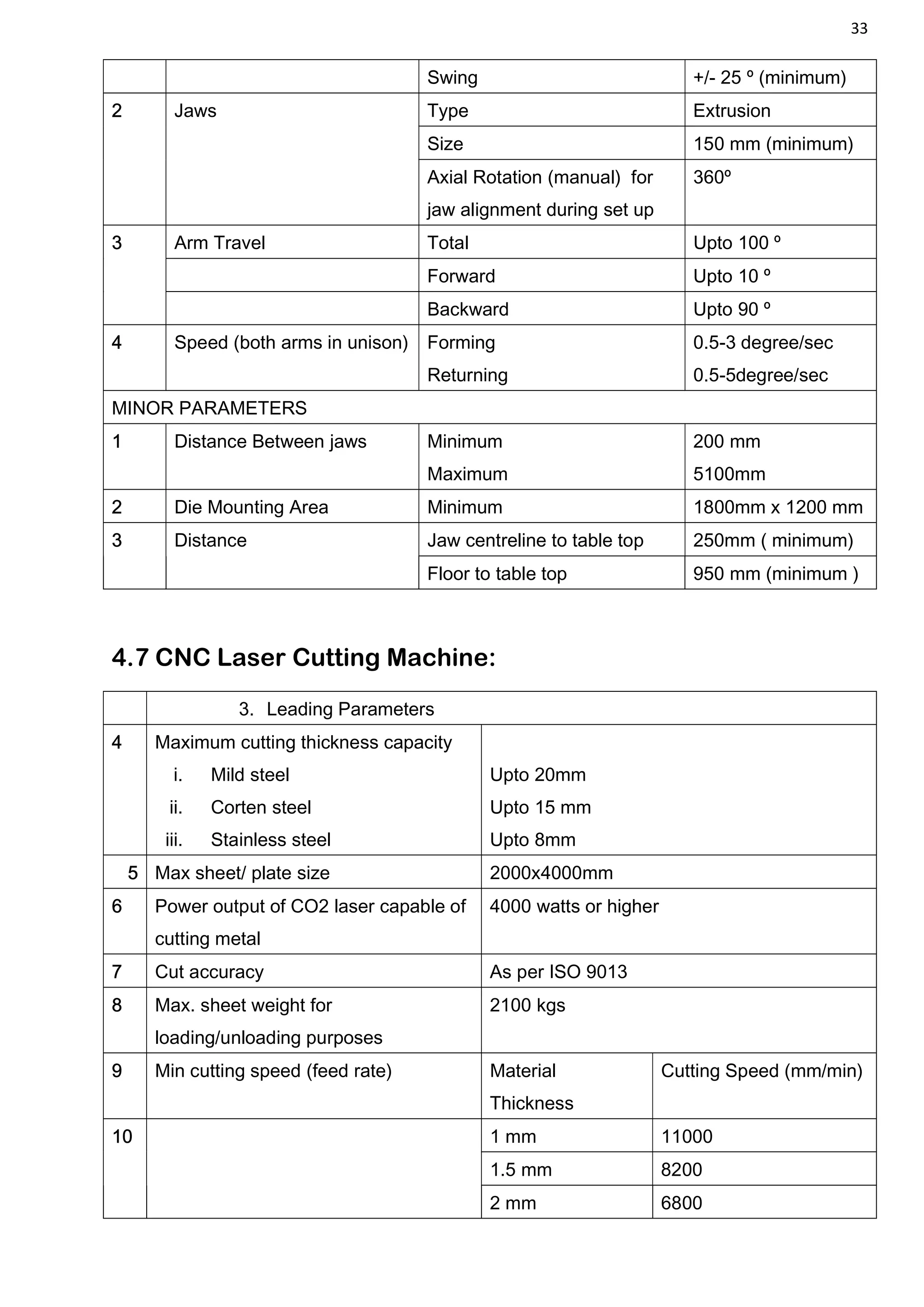

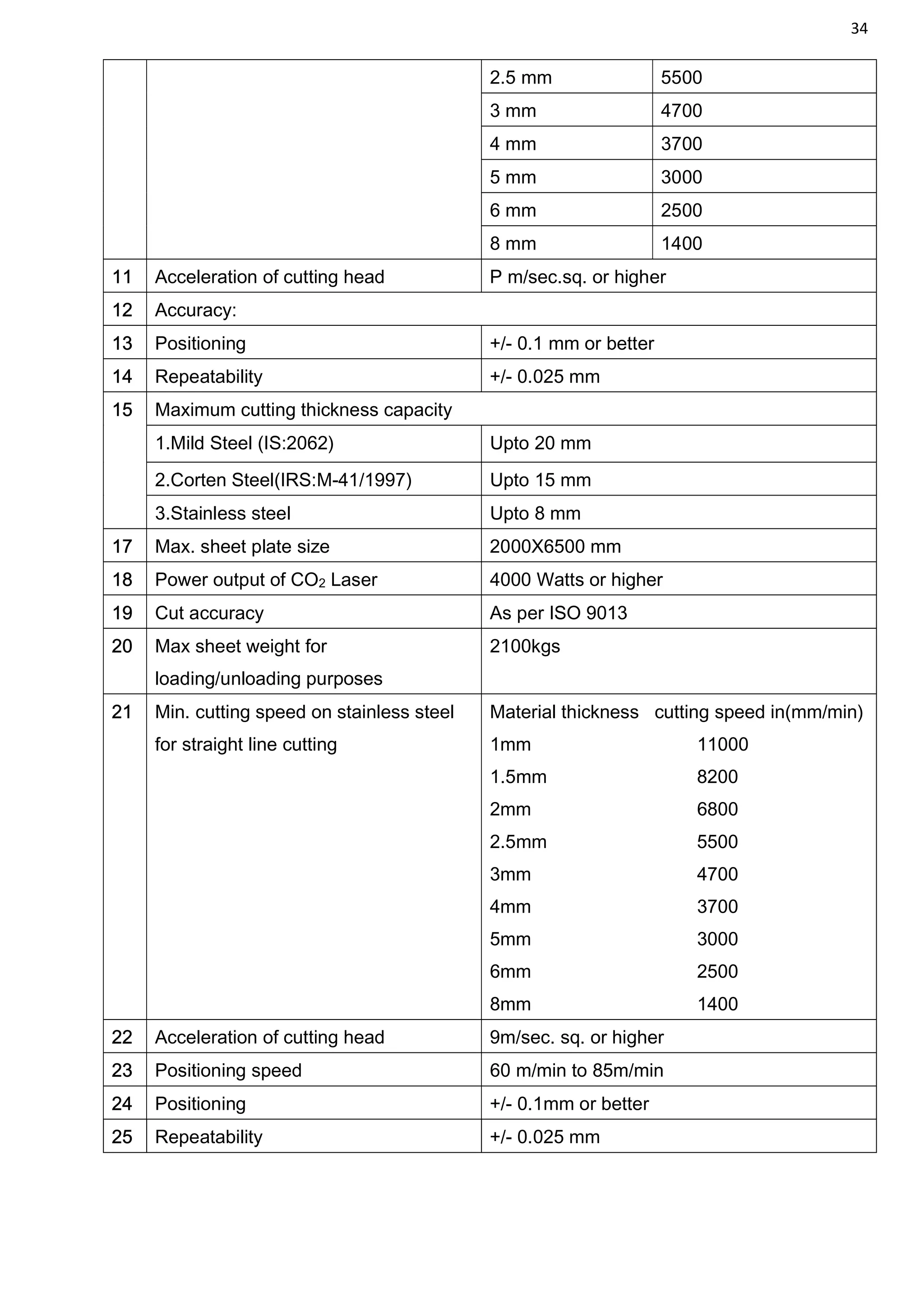

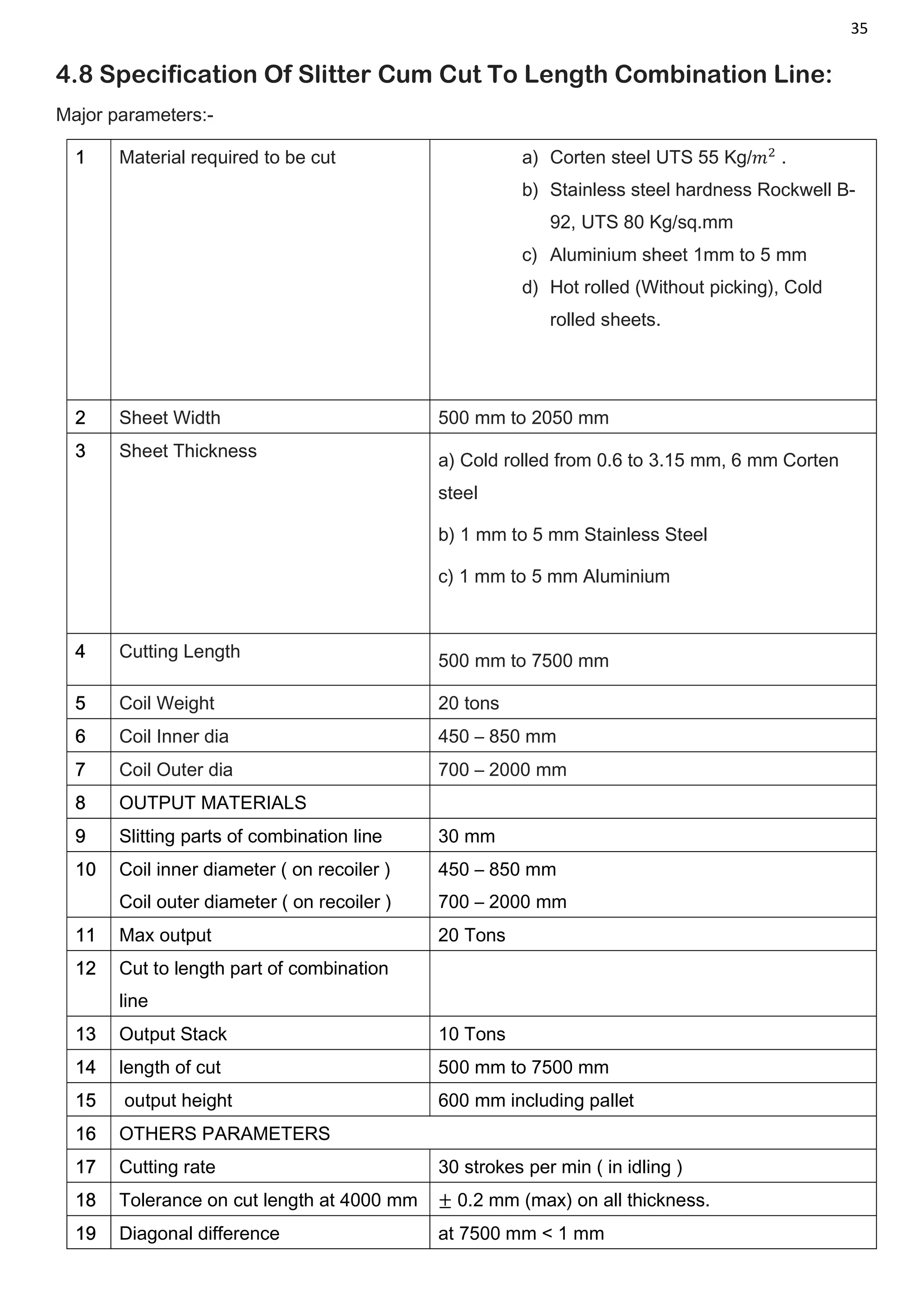

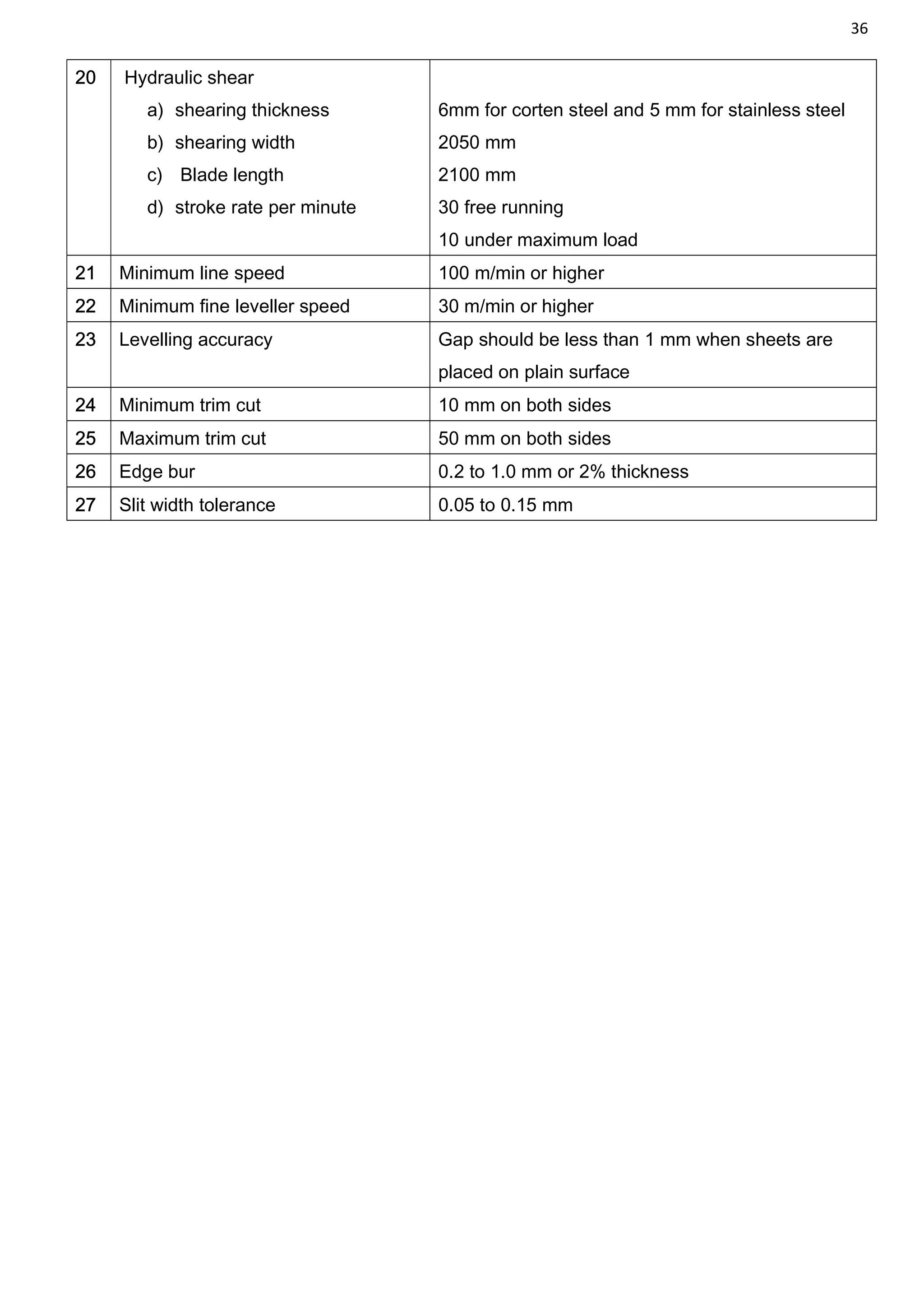

The document provides an overview of LHB coaches manufactured at the Modern Coach Factory in Raebareli, India. It discusses the history and development of LHB coaches, which were designed by German company Linke-Hofmann-Busch to operate at higher speeds of up to 160km/h on Indian rail lines. It also describes the various types of LHB coaches produced, the annual production rates, and the technical details of LHB coaches including their bogies, couplers, air conditioning, toilets, and other equipment. The document concludes with general specifications of some of the key machines used in the shell manufacturing process at the factory.