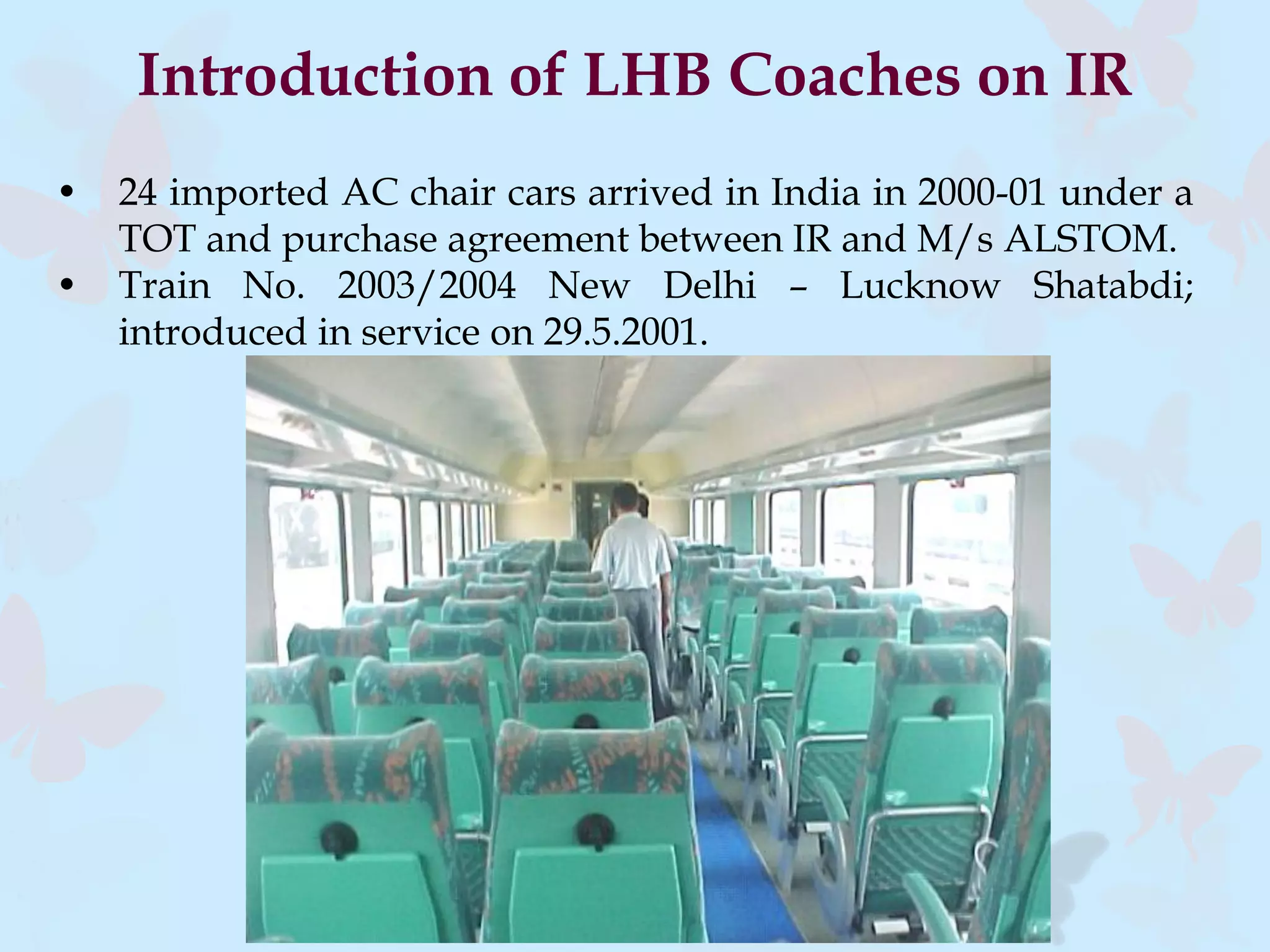

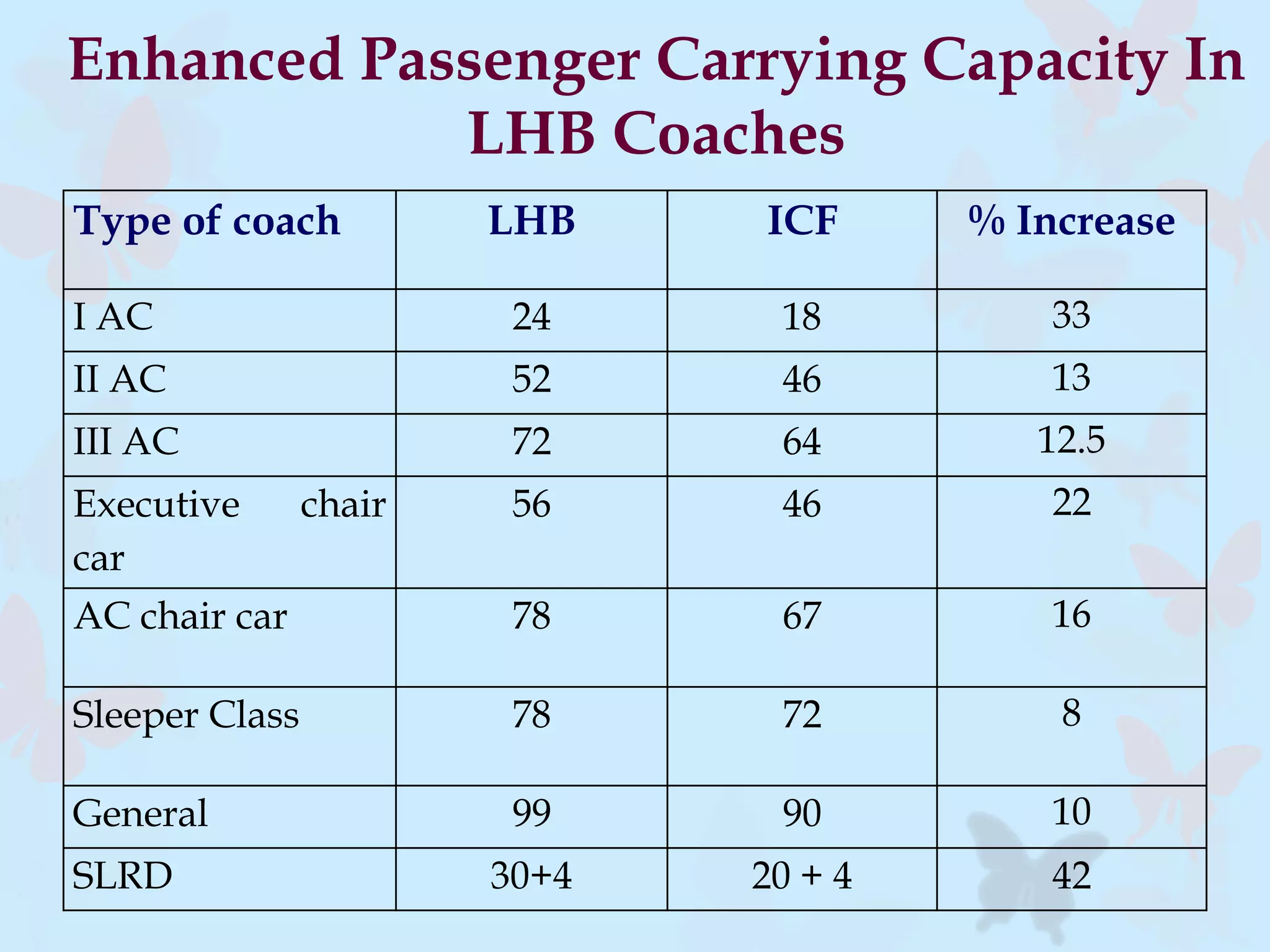

The document discusses LHB coaches that were introduced on Indian Railways in 2001. It provides details on the salient features, maintenance issues, and advantages of LHB coaches compared to ICF coaches. Some key points include:

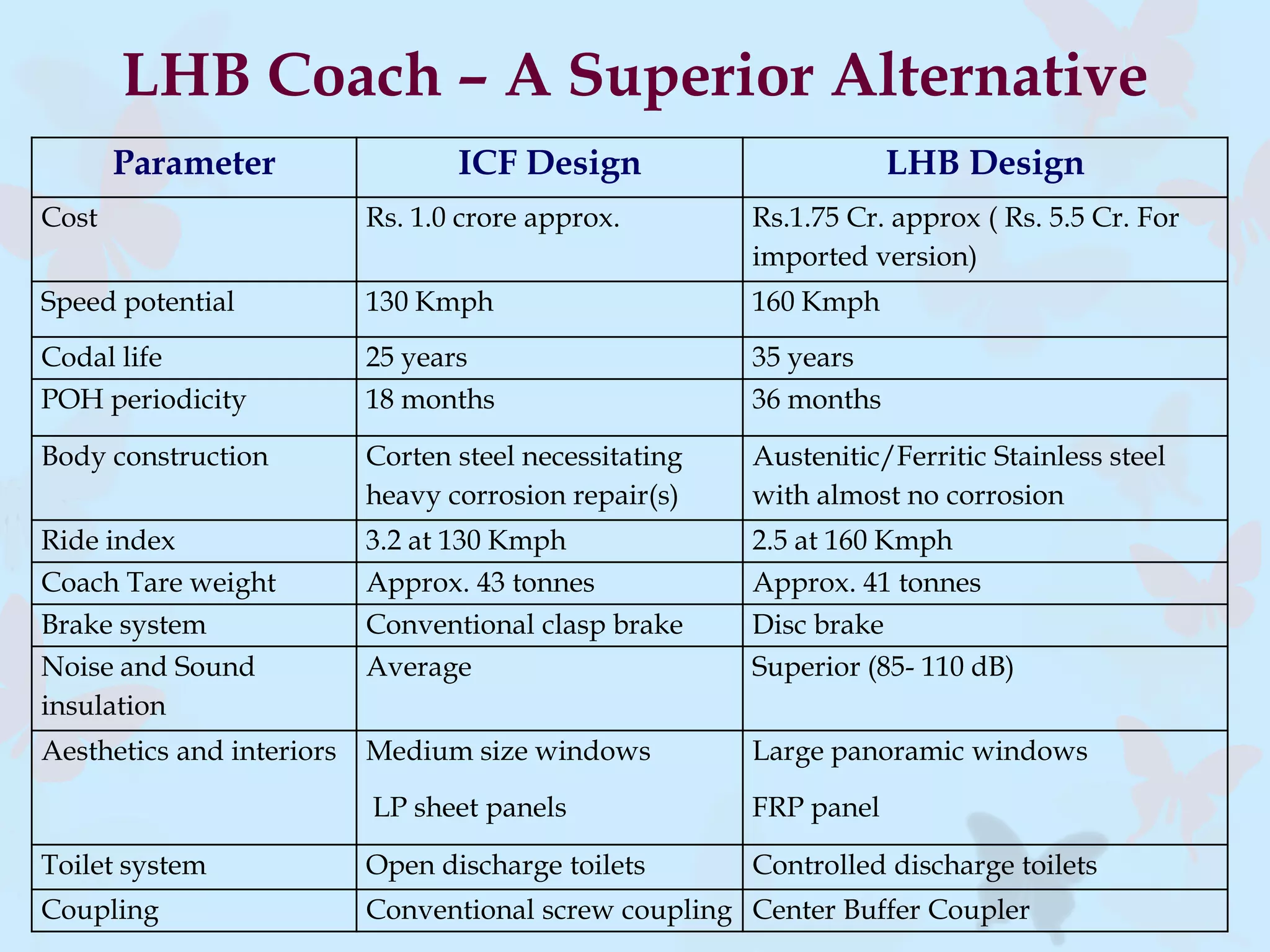

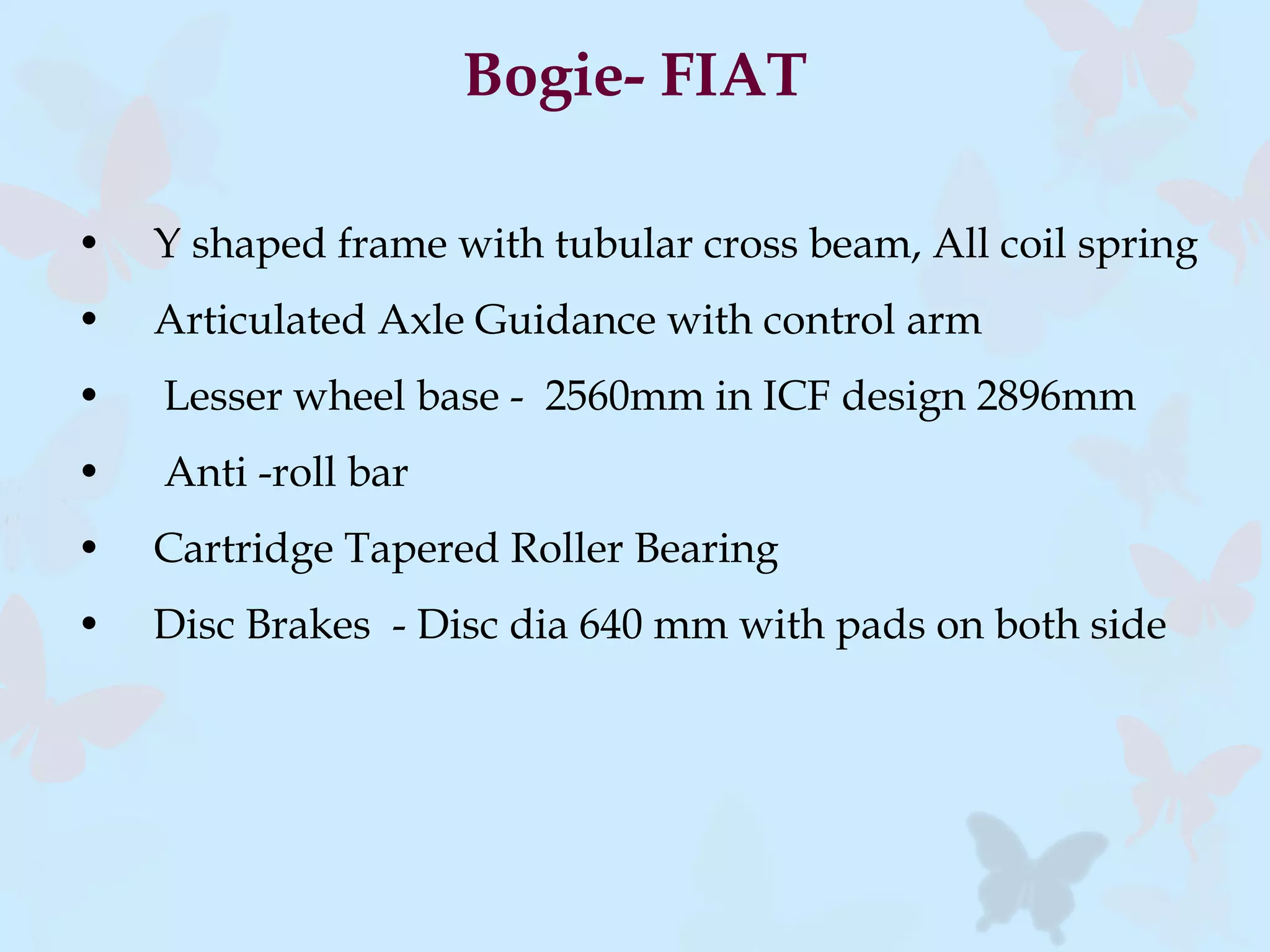

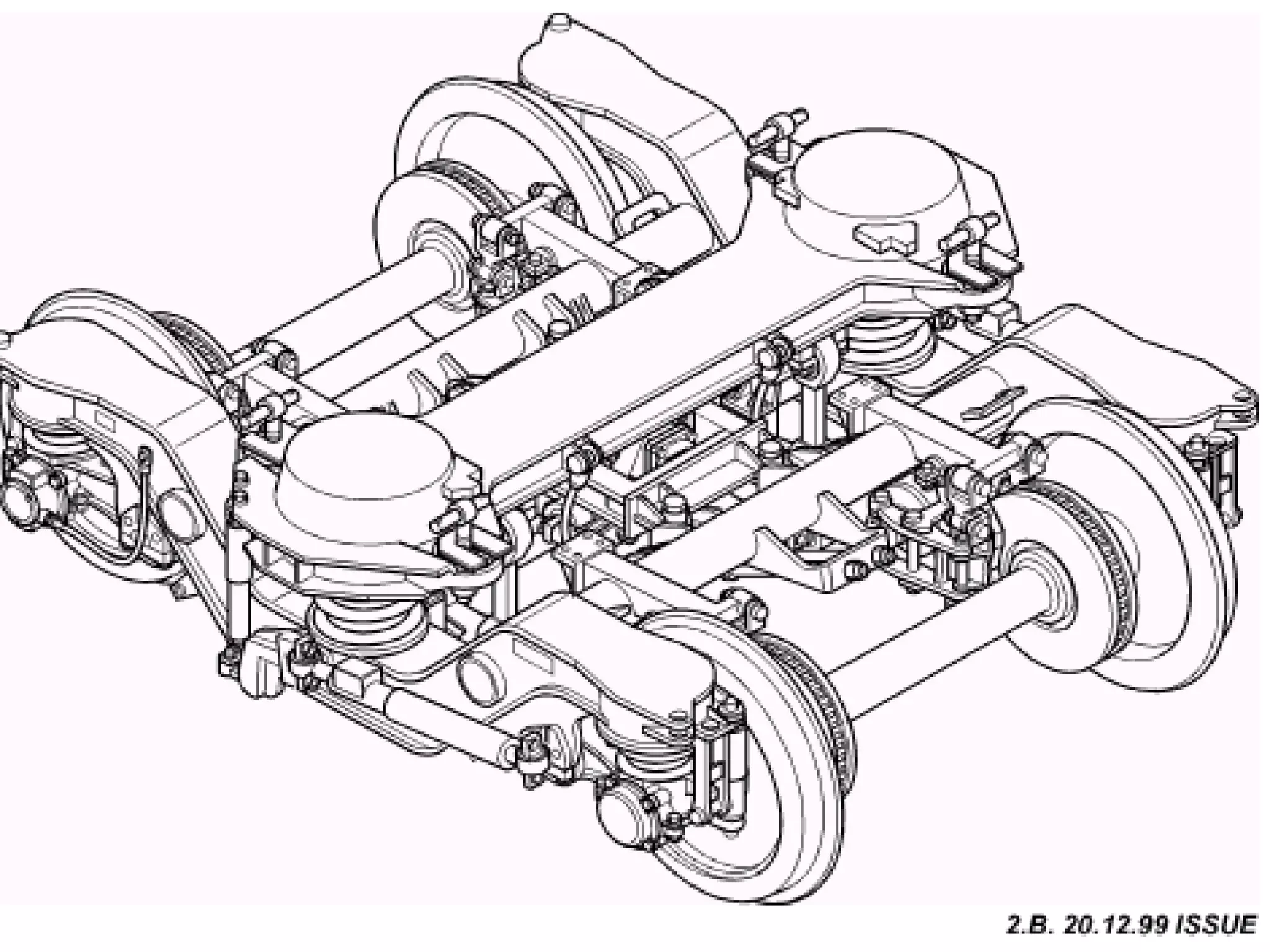

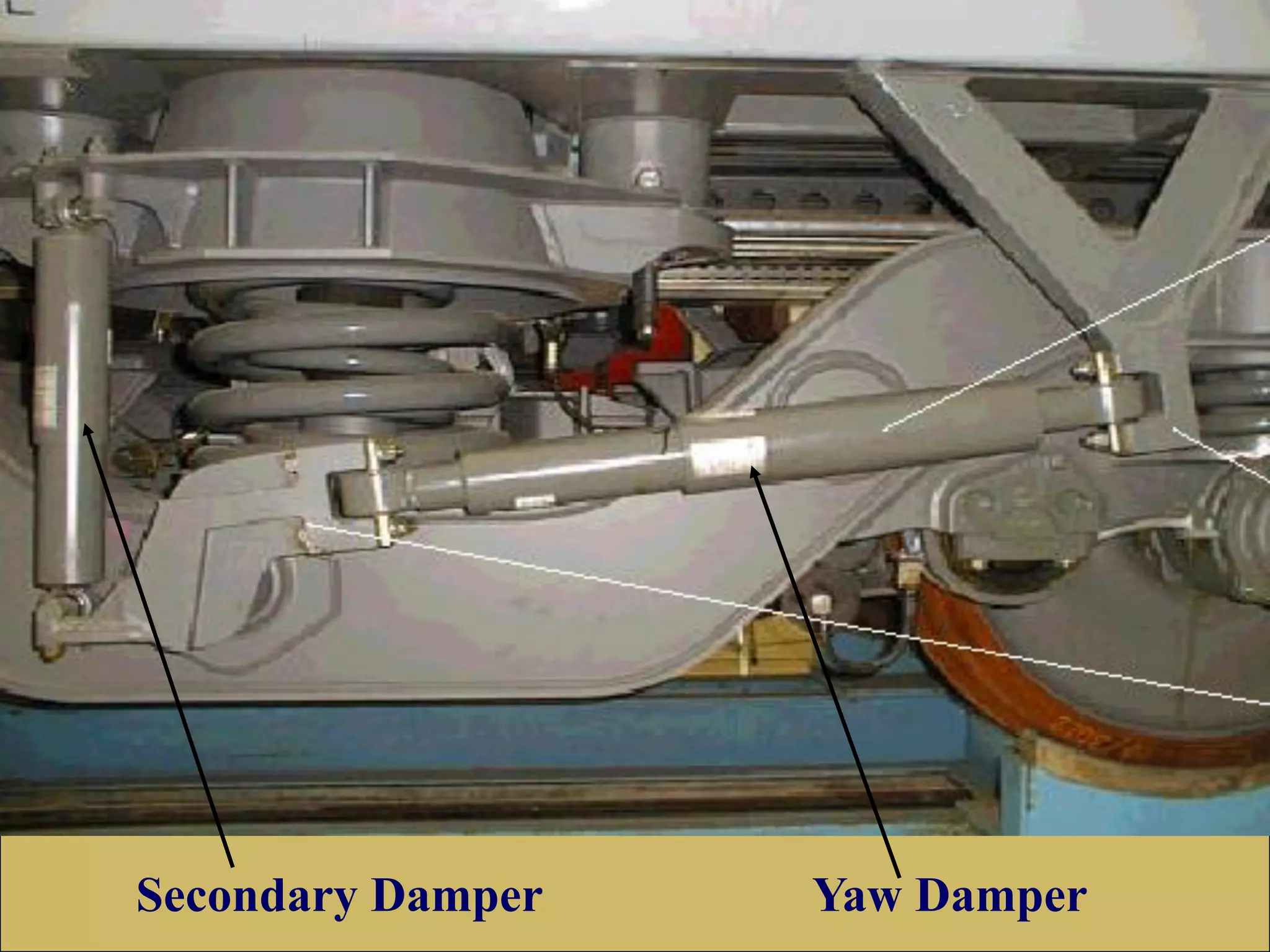

- LHB coaches have higher speeds of 160 kmph, longer lifespan of 35 years, and better ride quality compared to ICF coaches.

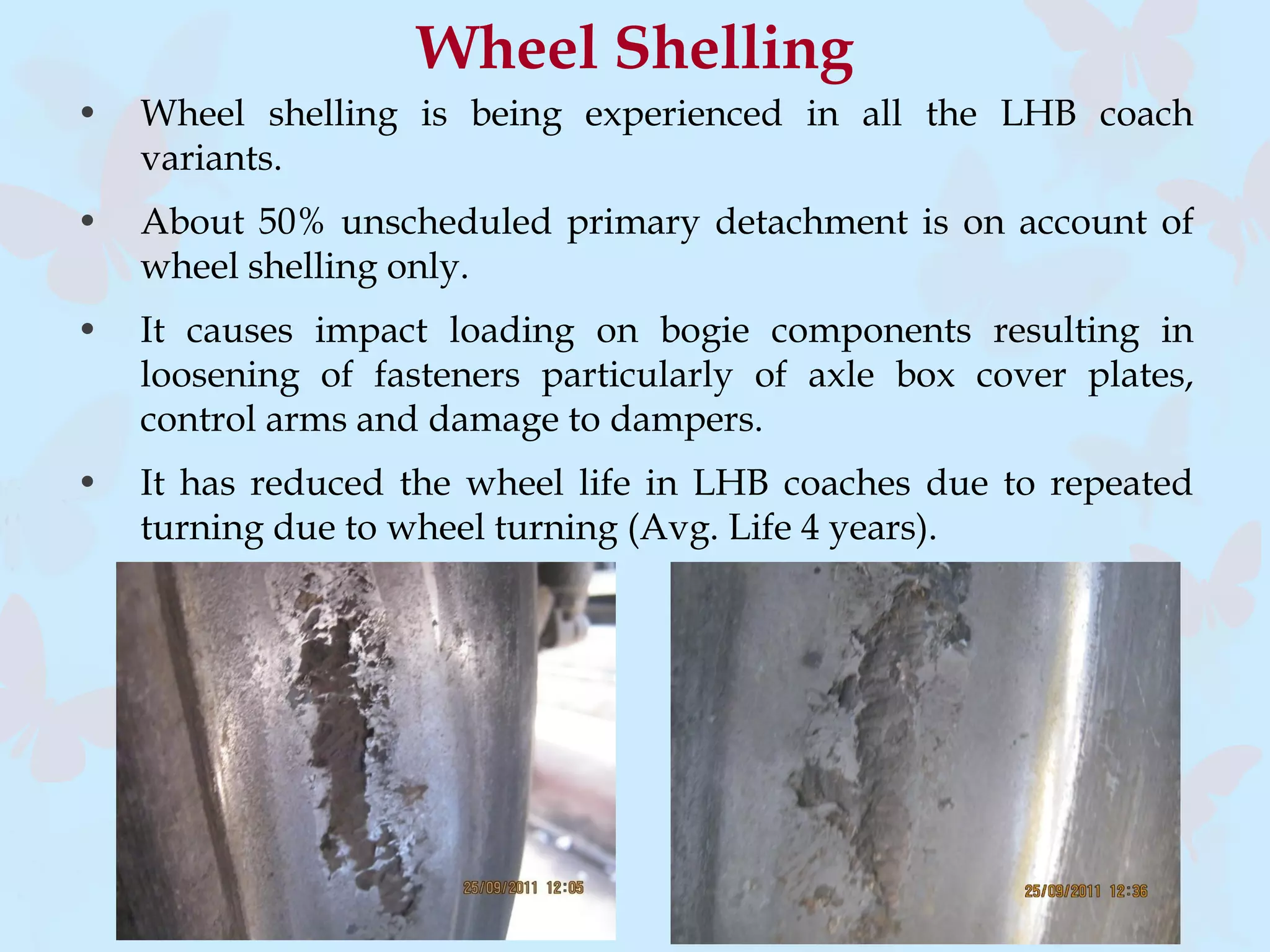

- Common maintenance issues include wheel shelling, brake disc breakages, and roller bearing failures.

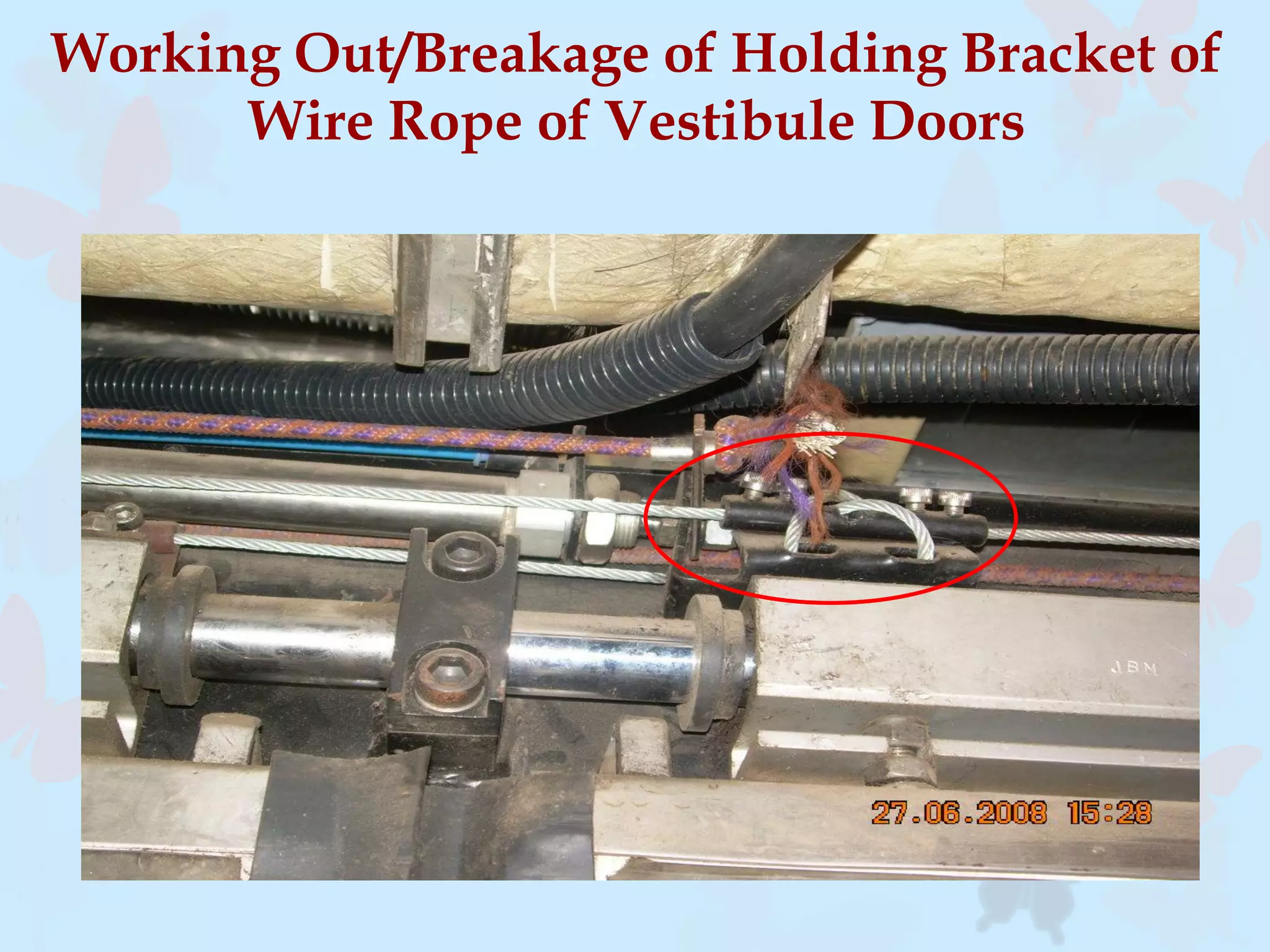

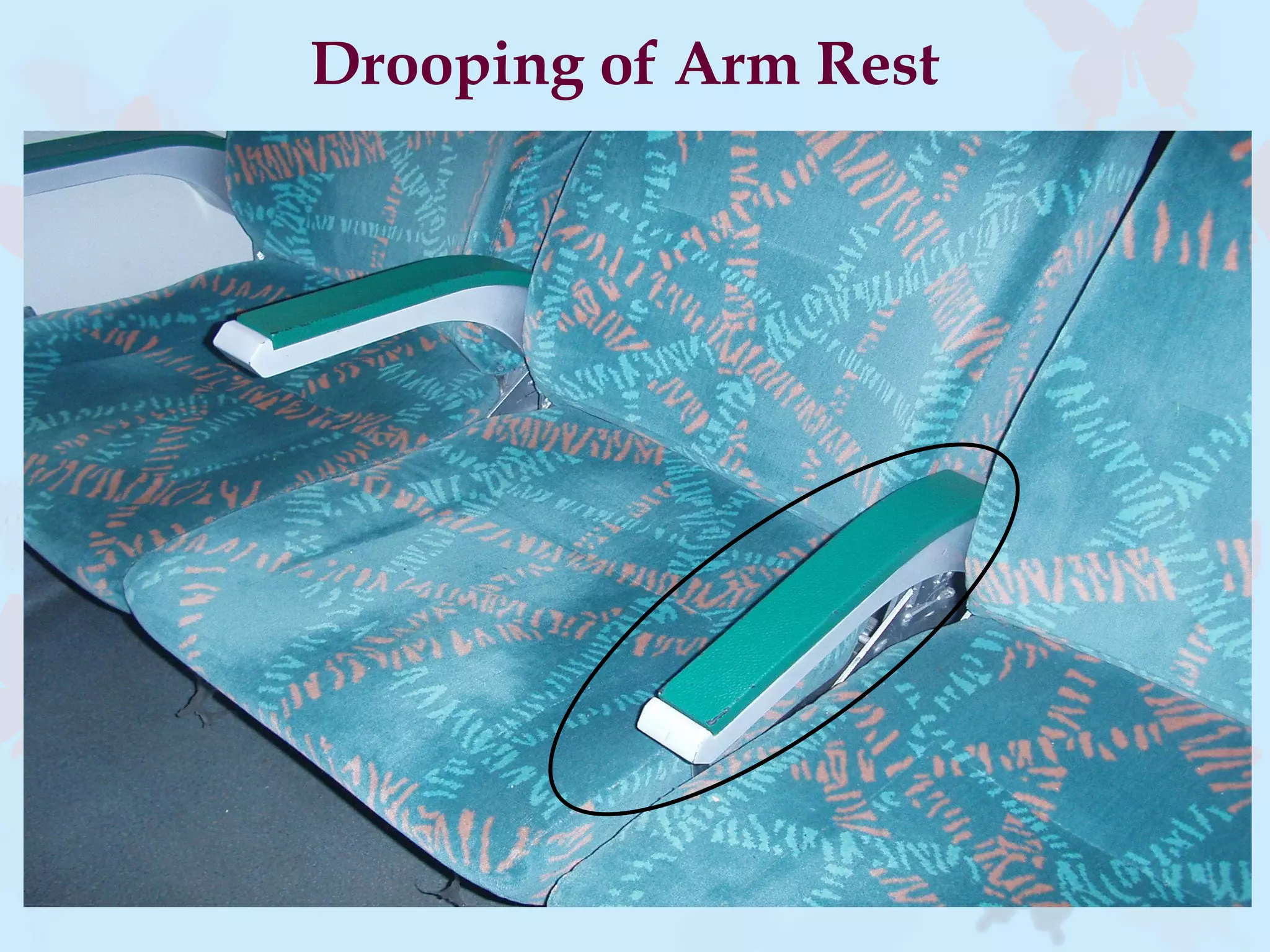

- Areas needing regular maintenance attention are doors, seats, fittings and amenities like toilets, windows, and louvers that are prone to theft.

- Procuring spare parts for maintenance is challenging due to limited vendors for specialized components