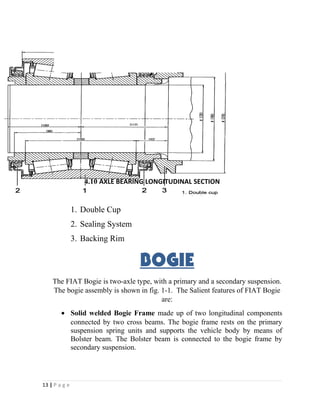

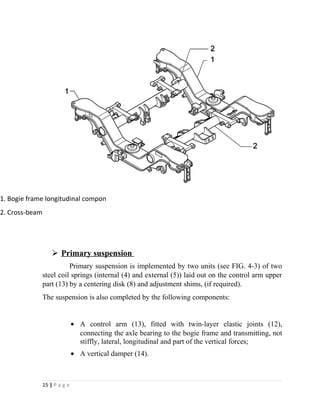

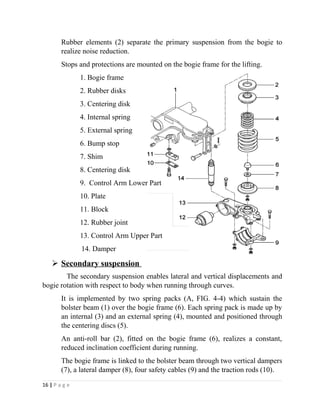

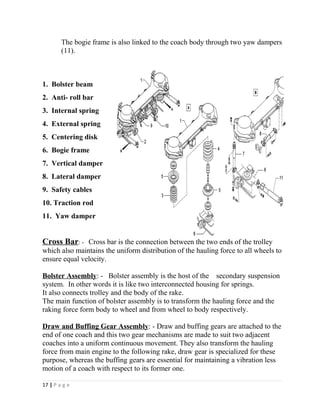

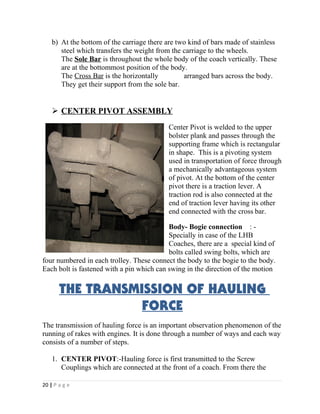

This document is a summer training report submitted by Vicky Kumar to fulfill requirements for a Bachelor of Technology degree. It provides an overview of Vicky's training at the East Central Railway Danapur, where they learned about various mechanical engineering departments and processes. The report then details LHB coaches, which are newer than traditional ICF coaches and offer benefits like higher speed capabilities, reduced corrosion, and improved passenger comfort and safety. Key components of LHB coaches described include the bogie, shell, center pivot assembly, air brake system, and controlled discharge toilet system.