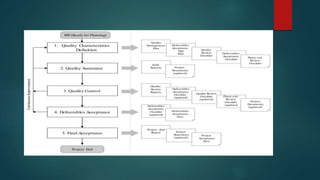

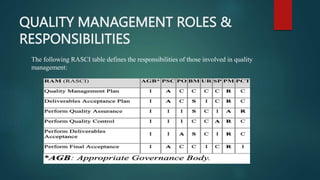

Vertex Engineering is presenting their quality management plan for a construction project in Bahria Town, Karachi. The plan outlines their quality objectives, which include verifying control testing, monitoring design and progress, checking dimensions, and inspecting materials. It describes the quality management process, which involves reviewing drawings and maintaining schedule and budget compliance. Key roles and responsibilities are defined, along with the tools and techniques that will be used, such as audits, checklists, and reports. Field inspections, material testing procedures, and quality reports are also covered.