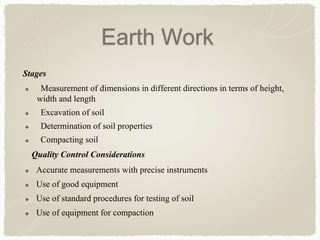

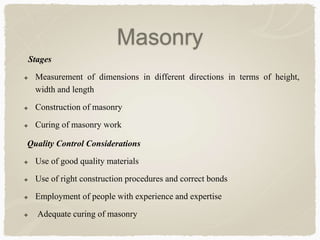

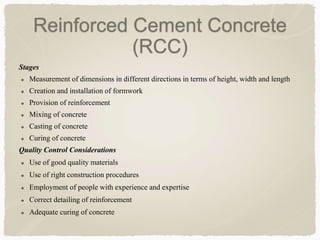

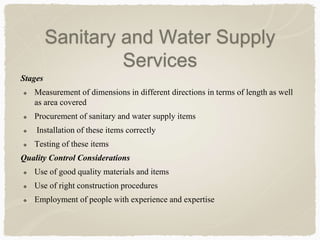

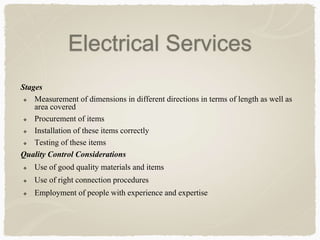

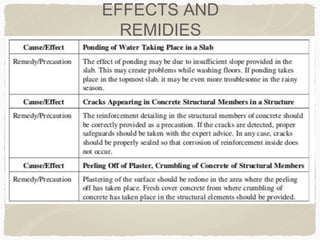

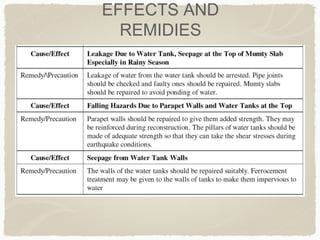

The document discusses the importance of inspection and quality control in construction projects, emphasizing that inspection is crucial for maintaining quality while quality control involves broader measures. It outlines various stages of inspection and the impact of quality on project efficiency, cost reduction, and owner satisfaction. Additionally, key considerations for quality control in terms of materials, skills, and guidelines are highlighted.