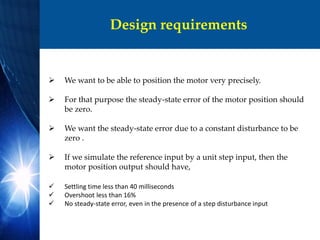

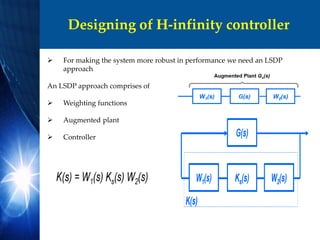

This document summarizes the design of an H-infinity controller for DC motor positioning. It describes modeling the DC motor transfer function and state space representation. PID control is designed to meet requirements of zero steady state error and settling time less than 40ms with overshoot below 16%. Simulation shows the closed loop response meets requirements. Finally, an H-infinity controller is designed using weighting functions to further improve robustness.

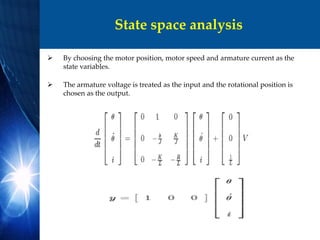

![State space representation

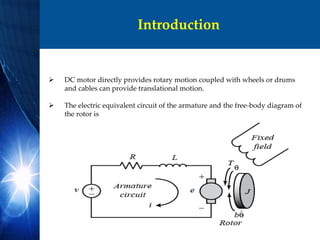

A = [0 1 0; 0 -b/J K/J;0 -K/L -R/L];

B = [0 ; 0 ; 1/L];

C = [1 0 0];

D = [0];

motor_ss = ss (A,B,C,D)

• motor_ss =

•

• a =

• x1 x2 x3

• x1 0 1 0

• x2 0 -1.087 8487

• x3 0 -9964 -1.455e+06

•

• b =

• u1

• x1 0

• x2 0

• x3 3.636e+05

•

• c =

• x1 x2 x3

• y1 1 0 0

•

• d =

• u1

• y1 0

Continuous-time state-space model.](https://image.slidesharecdn.com/a496f137-b756-41f3-9234-d1fdef0bcbc0-150504013204-conversion-gate02/85/Project-Presentation-10-320.jpg)

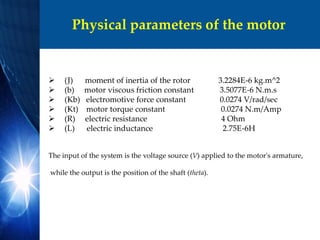

![Model Order Reduction

poles = pole(P_motor);

rP_motor = minreal(P_motor*(s/max(abs(poles)) + 1))

Reduced order transfer function:

rP_motor = 2122

-------------

s^2 + 59.23 s

By checking that the other poles have not been affected by we again use the same

pole command as was used previously,

poles(1), poles(3)] ans = 0 ans = -59.2260](https://image.slidesharecdn.com/a496f137-b756-41f3-9234-d1fdef0bcbc0-150504013204-conversion-gate02/85/Project-Presentation-14-320.jpg)

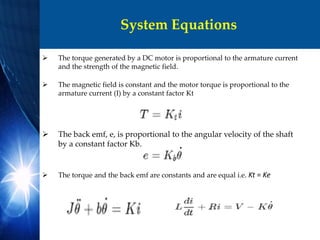

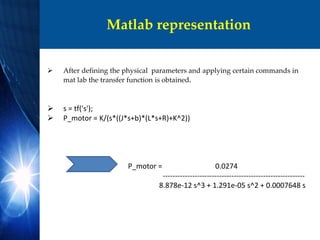

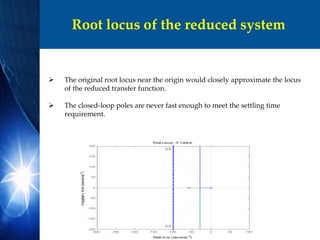

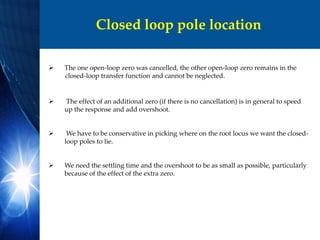

![Determining gain

Large damping corresponds to points on the root locus near the real axis.

A fast response corresponds to points on the root locus far to the left of the

imaginary axis.

To find the gain corresponding to a point on the root locus,

the rlocfind command is used.

[k,poles] = rlocfind (rsys_ol)

Select a point is selected on the root locus on left side of the loop, close to the

real axis.

These pole locations indicate that the response would have almost no

overshoot if it were a canonical second-order system.

However the presence of the zero in this system will add some overshoot.](https://image.slidesharecdn.com/a496f137-b756-41f3-9234-d1fdef0bcbc0-150504013204-conversion-gate02/85/Project-Presentation-20-320.jpg)

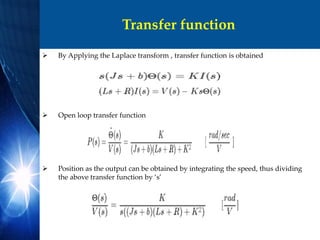

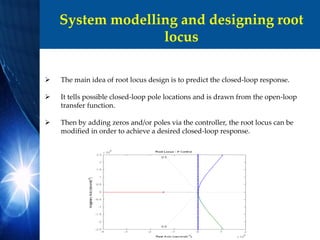

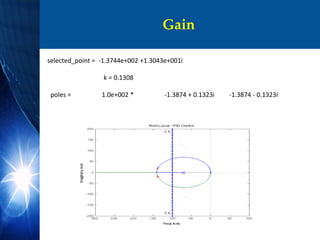

![Simulation and results

W1=0.1*(s+100)/(100*s+1);

W2=0.1;

P=augw( P_motor,W1,W2);

GAM=0;

k = 0.1308

PM = 50.3868

• pzmap(sys_cl)

• damp(sys_cl)

• [Wn,zeta,poles] = damp(sys_cl)

• bode(sys_cl)

• zeta = -log(.16) / sqrt( pi^2 + (log(.16))^2 );

• PM = 100*zeta](https://image.slidesharecdn.com/a496f137-b756-41f3-9234-d1fdef0bcbc0-150504013204-conversion-gate02/85/Project-Presentation-25-320.jpg)