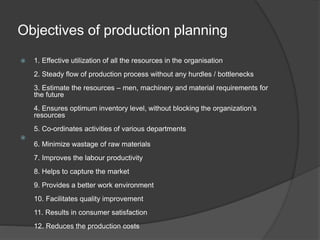

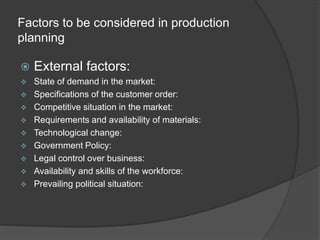

Production planning aims to make the manufacturing process as efficient as possible by developing a guide for product design and production. It considers factors like demand, resources, and regulations to effectively utilize resources, ensure steady production flow, and minimize waste and costs. Production control then monitors production to ensure plans are followed and objectives like on-time delivery, quality control and efficient resource use are met. It involves functions like routing, scheduling, dispatching and expediting to systematically direct production operations according to plans. Routing determines the optimal production process, sequence of operations and flow of work.