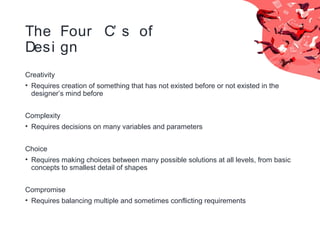

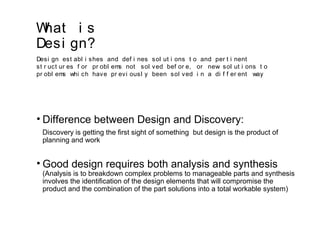

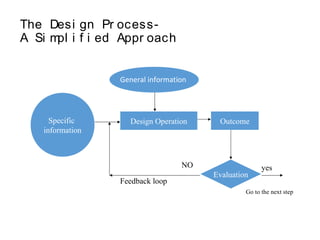

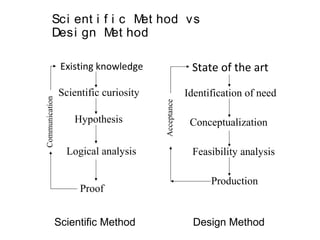

The document outlines the product design process and methodology. It discusses the four C's of design - creativity, complexity, choice, and compromise. It then describes the steps in the design process as conceptual design, embodiment design, detail design, planning for manufacture, distribution, use, and retirement of the product. Each step is briefly explained. The document also compares the scientific method to the design method.