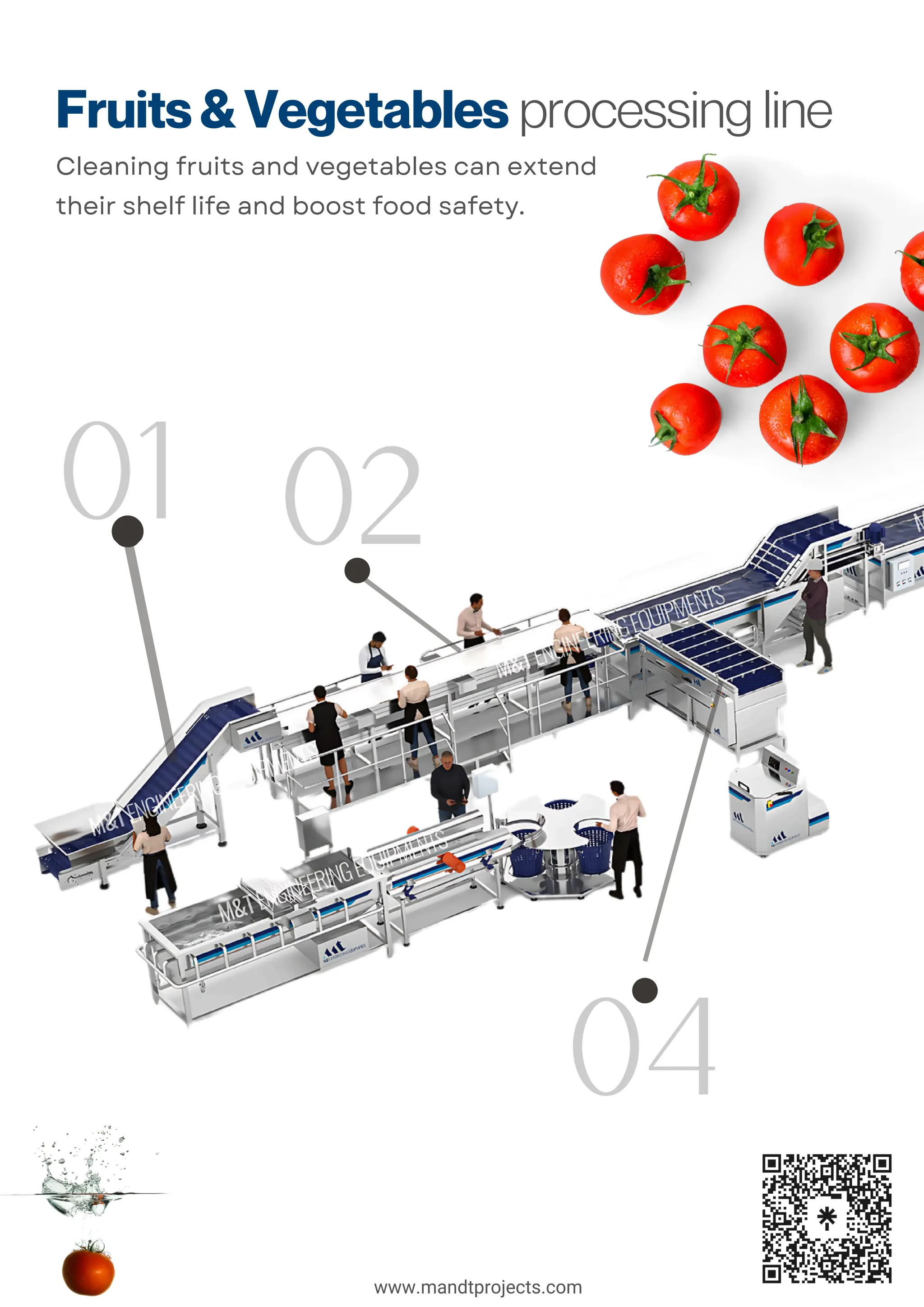

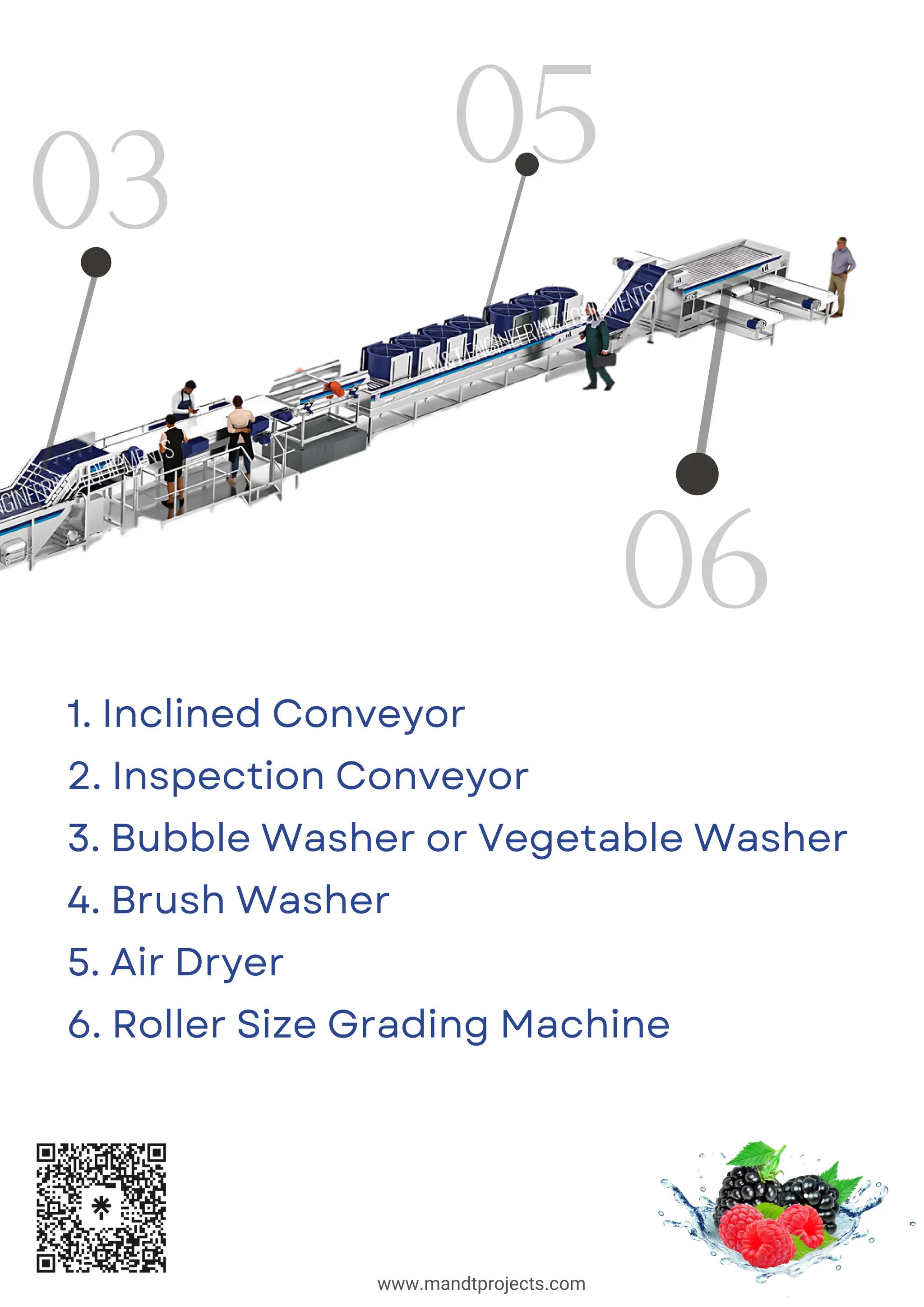

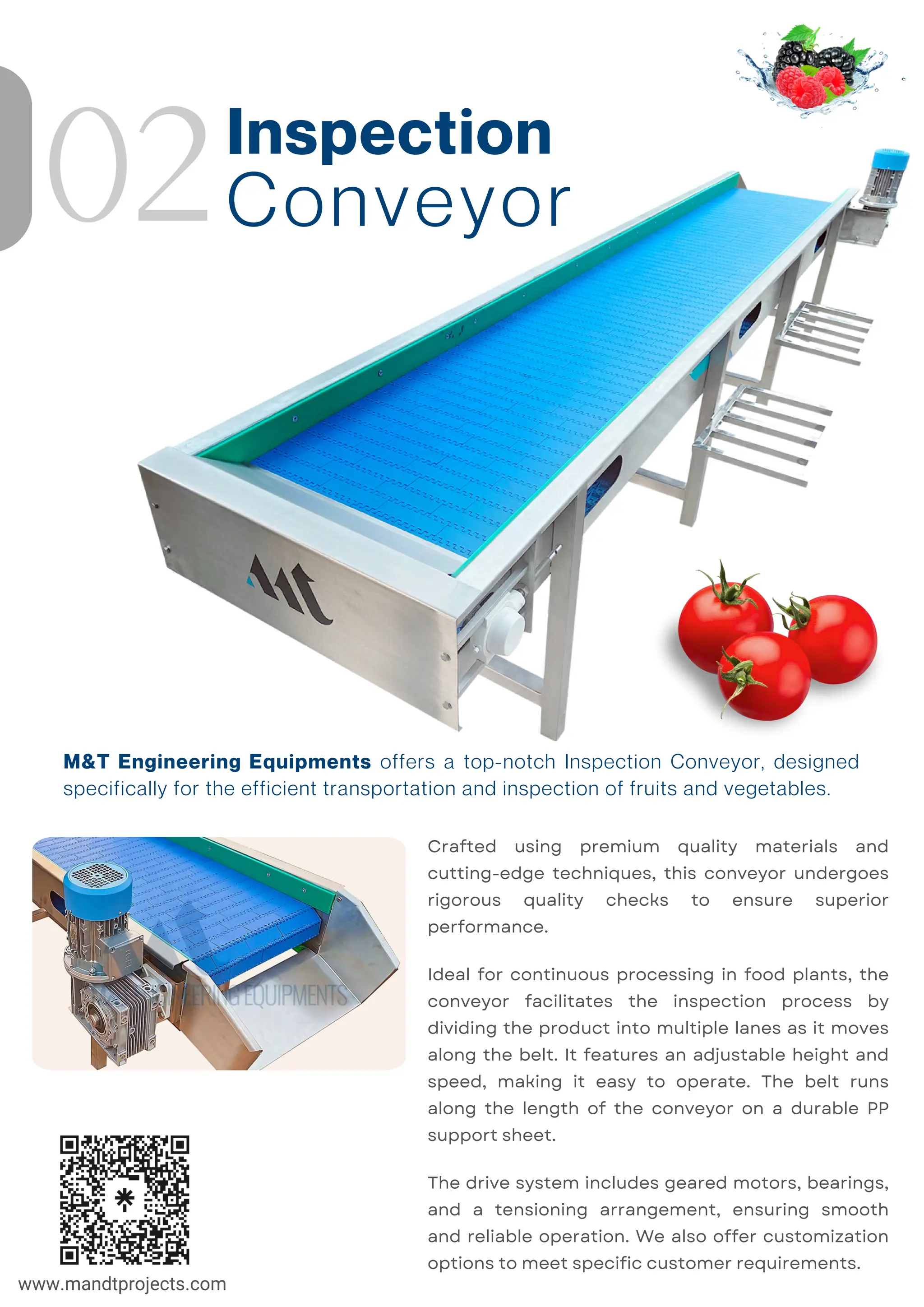

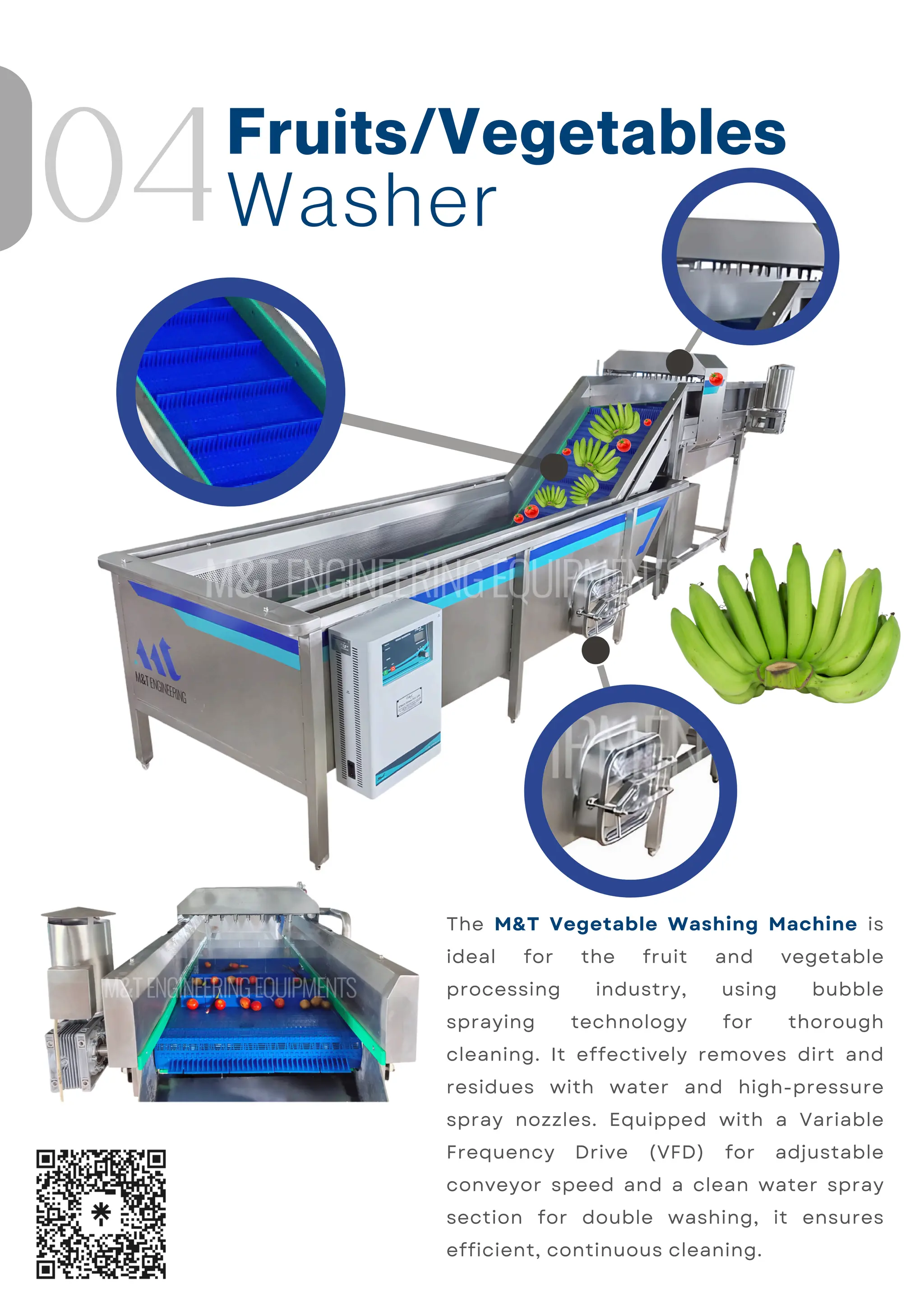

M&T Engineering Equipments specializes in providing advanced machinery for the fruit and vegetable processing industry, focusing on enhancing productivity while ensuring hygiene and quality. Their integrated lines include solutions for washing, grading, and packaging produce, benefiting from automation and advanced technologies. Additionally, they offer customizable options and complete turnkey solutions for various sectors, alongside storage facilities to extend shelf life.