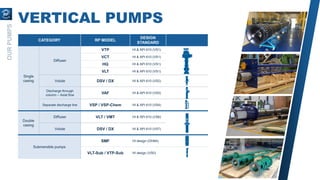

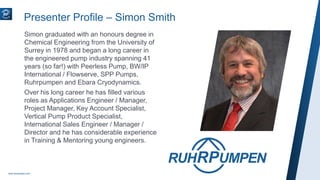

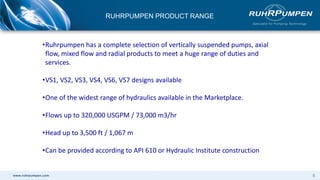

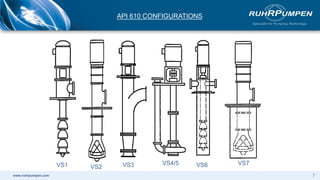

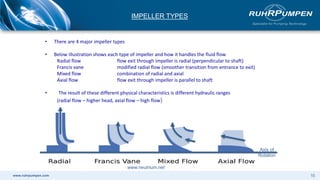

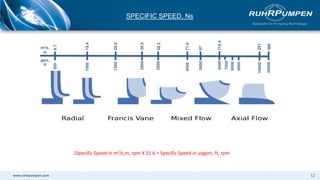

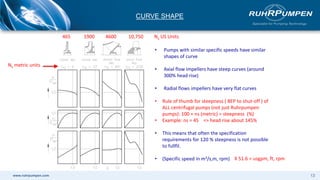

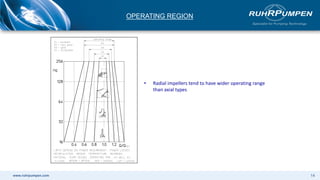

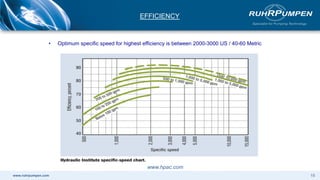

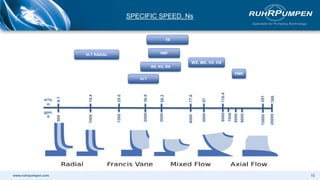

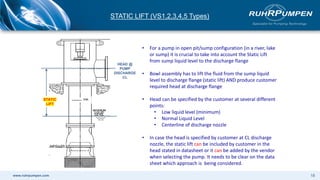

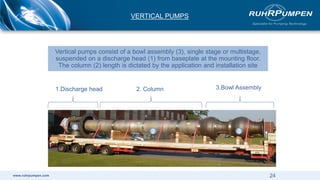

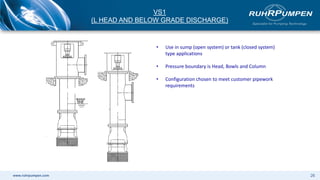

This document provides an overview of a training session on vertical pumps given by Simon Smith. It includes Simon's background and experience in the pump industry spanning 41 years. The session covers various types of vertical pumps including VS1, VS2, VS3 configurations. It discusses pump components, configurations, applications, specifications and operating principles such as specific speed, impeller types, curve shape and efficiency.

![A GLOBAL COMPANY

MANUFACTURING FACILITIES

USA [Tulsa]

Germany [Witten]

Mexico [Monterrey]

Brazil [Rio de Janeiro]

Argentina [Buenos Aires]

Egypt [Suez]

India [Chennai]

China [Changzhou]

Russia [Moscow]

United Kingdom [Lancing]

Manufacturing facility

& Service center

Service center](https://image.slidesharecdn.com/presentationpptsession11-verticalpumpspart1-vs123-231107121516-45dfdcfc/85/Presentation-PPT-Session-11-Vertical-Pumps-Part-1-VS1-2-3-pdf-62-320.jpg)