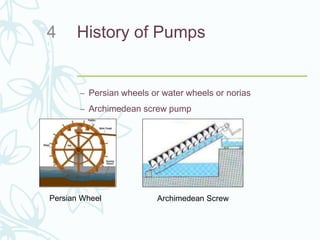

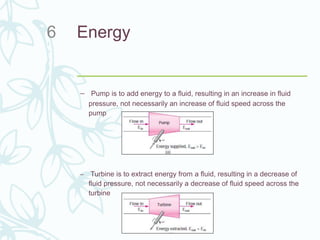

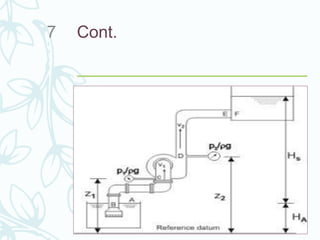

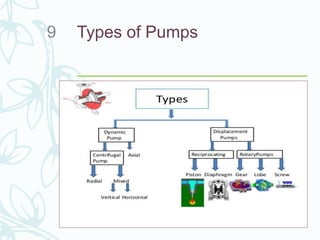

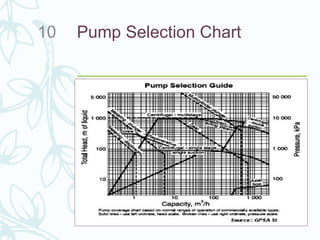

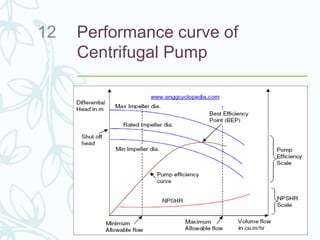

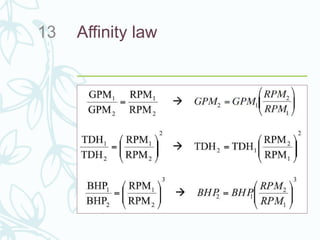

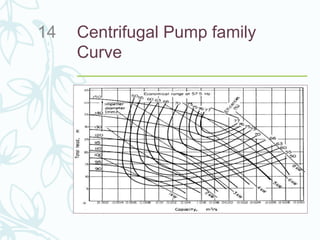

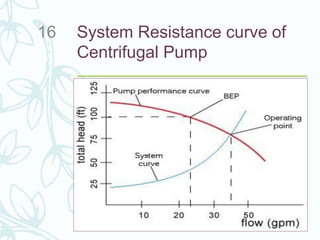

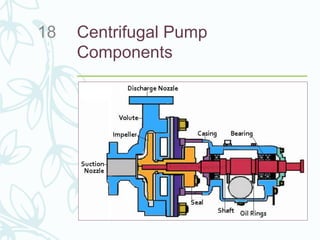

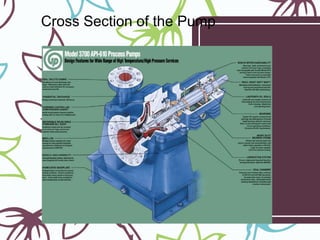

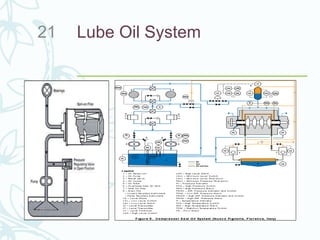

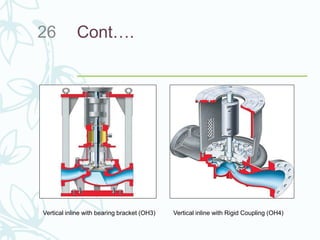

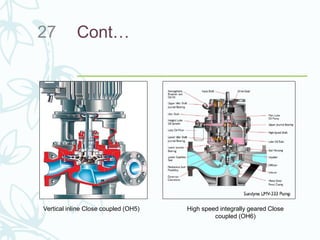

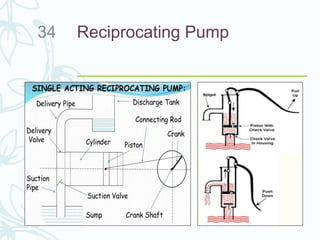

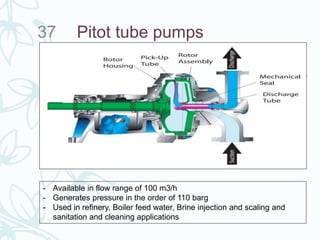

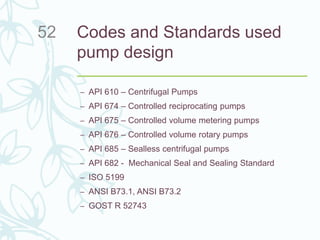

The document provides an extensive overview of pumps, including their history, types, performance characteristics, and design standards. It covers various pump types such as centrifugal, reciprocating, and special pumps, along with their applications and performance metrics. Additionally, the document discusses the API classifications and relevant codes and standards for pump design.