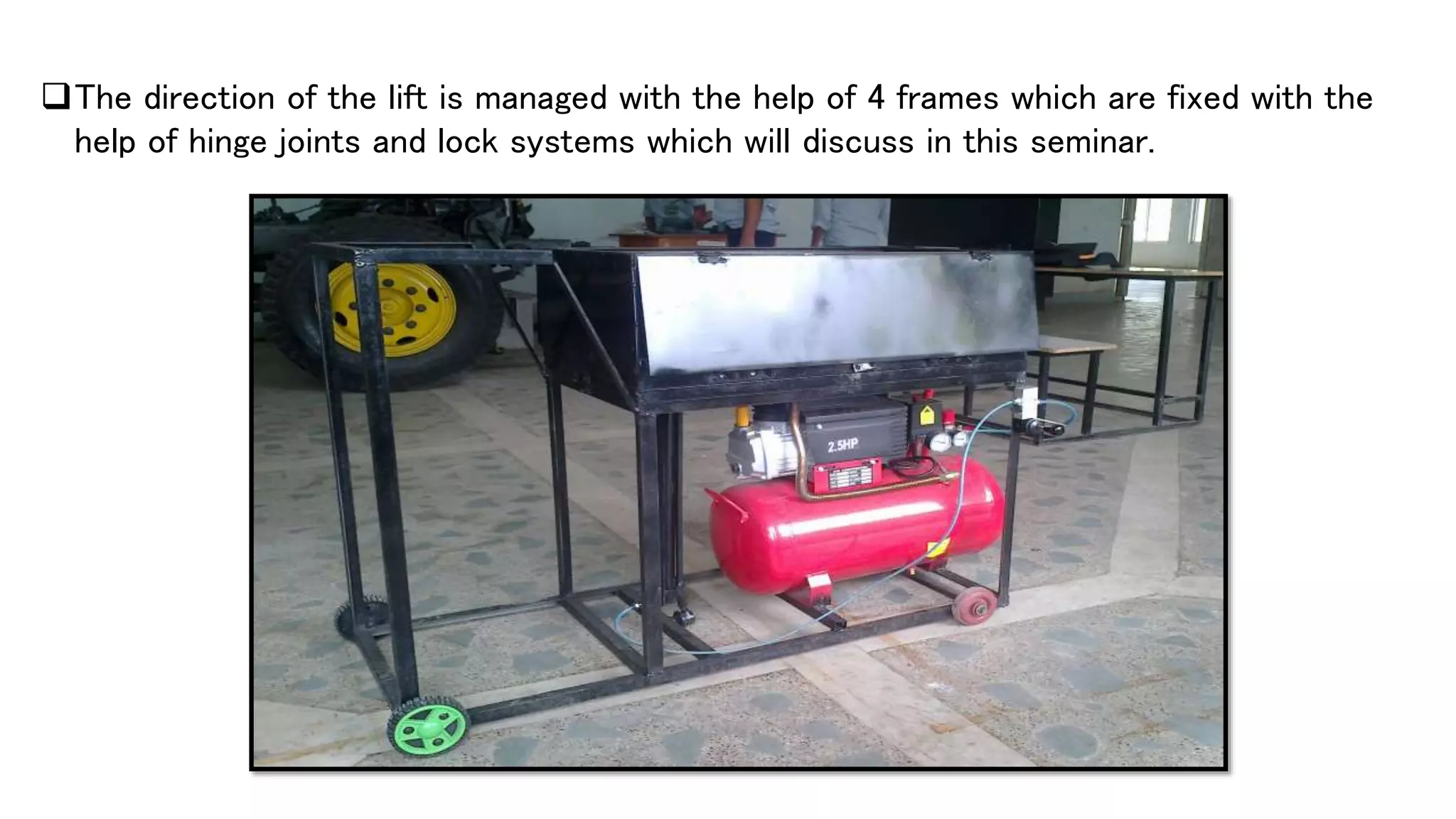

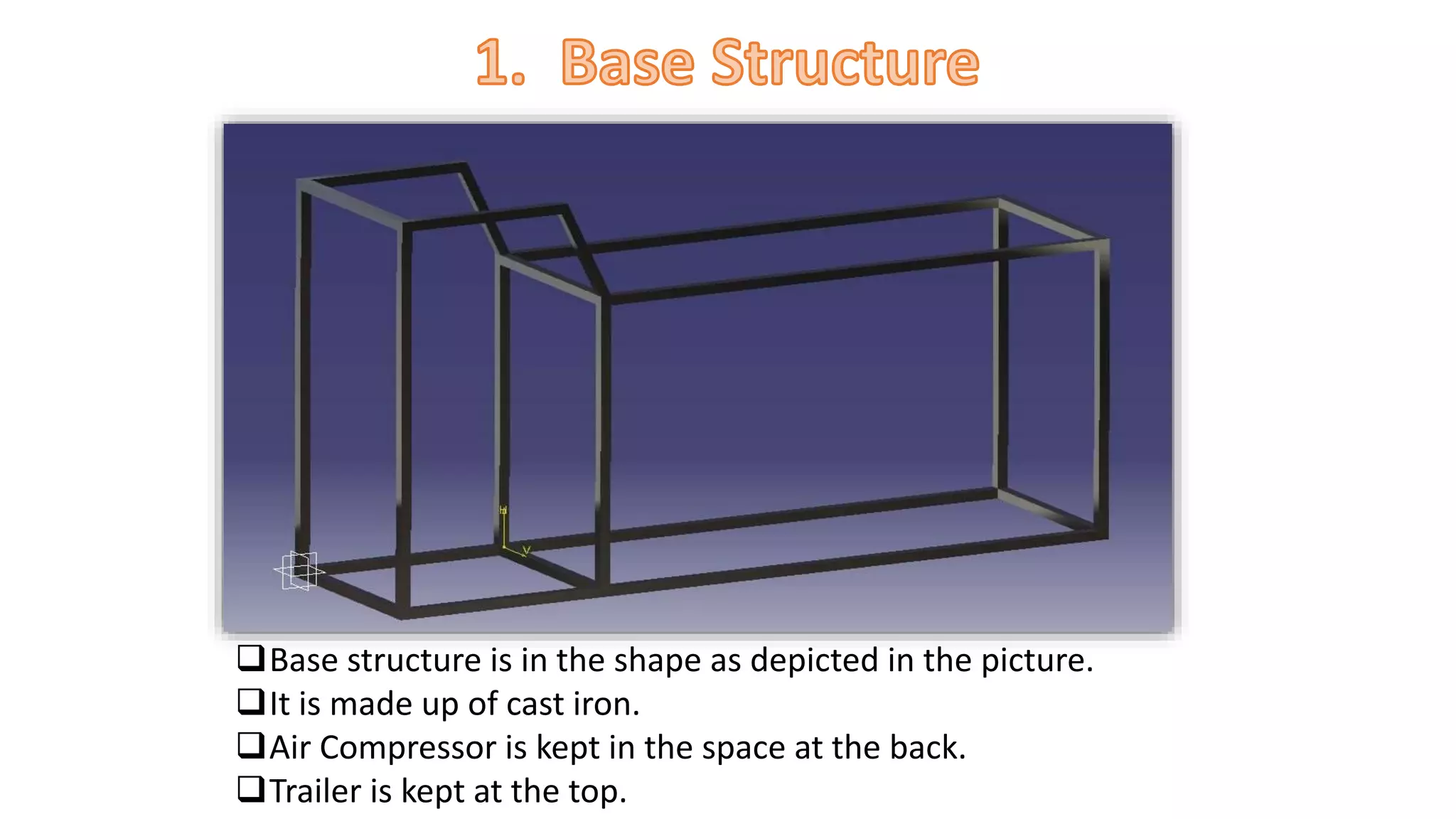

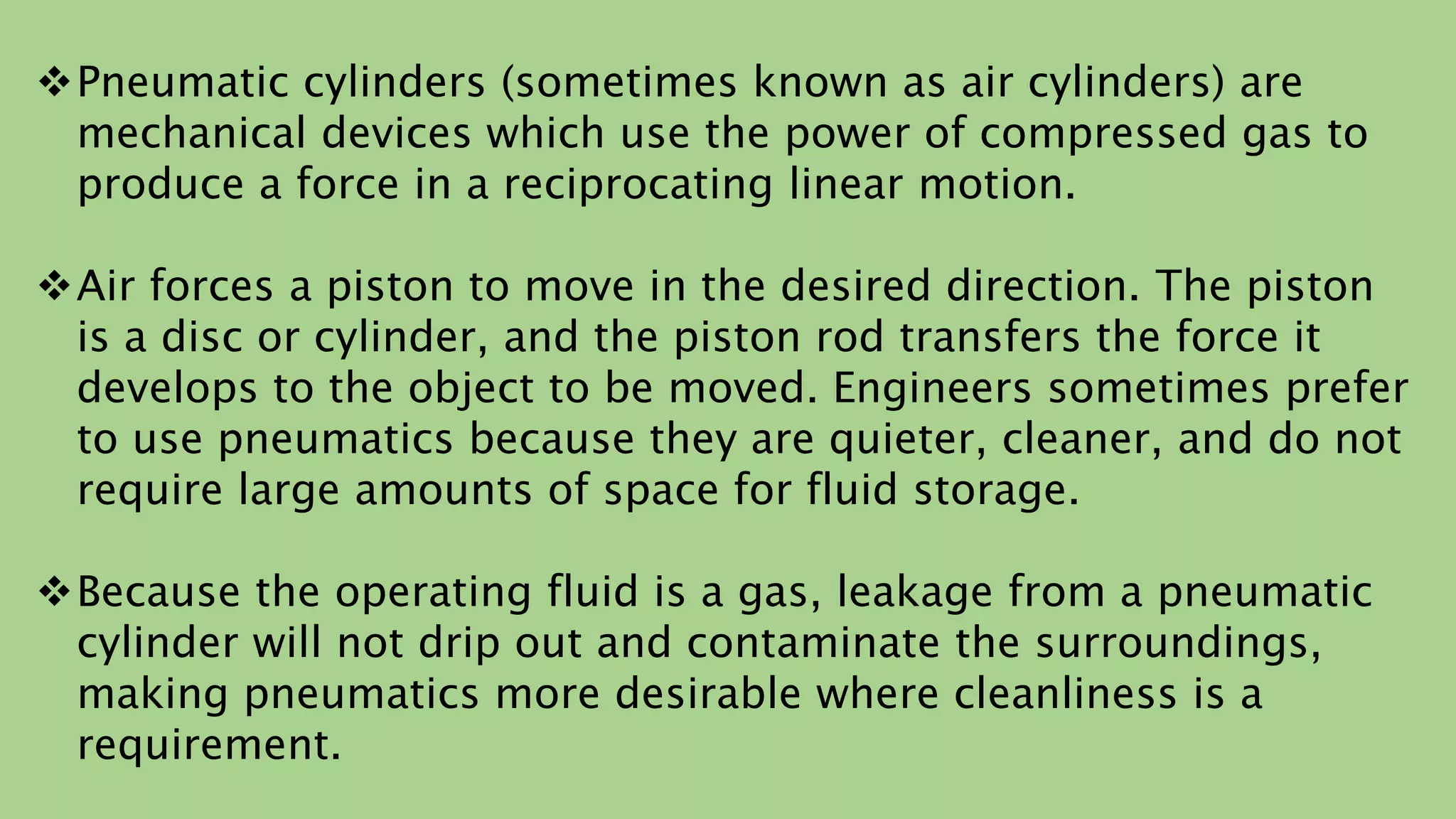

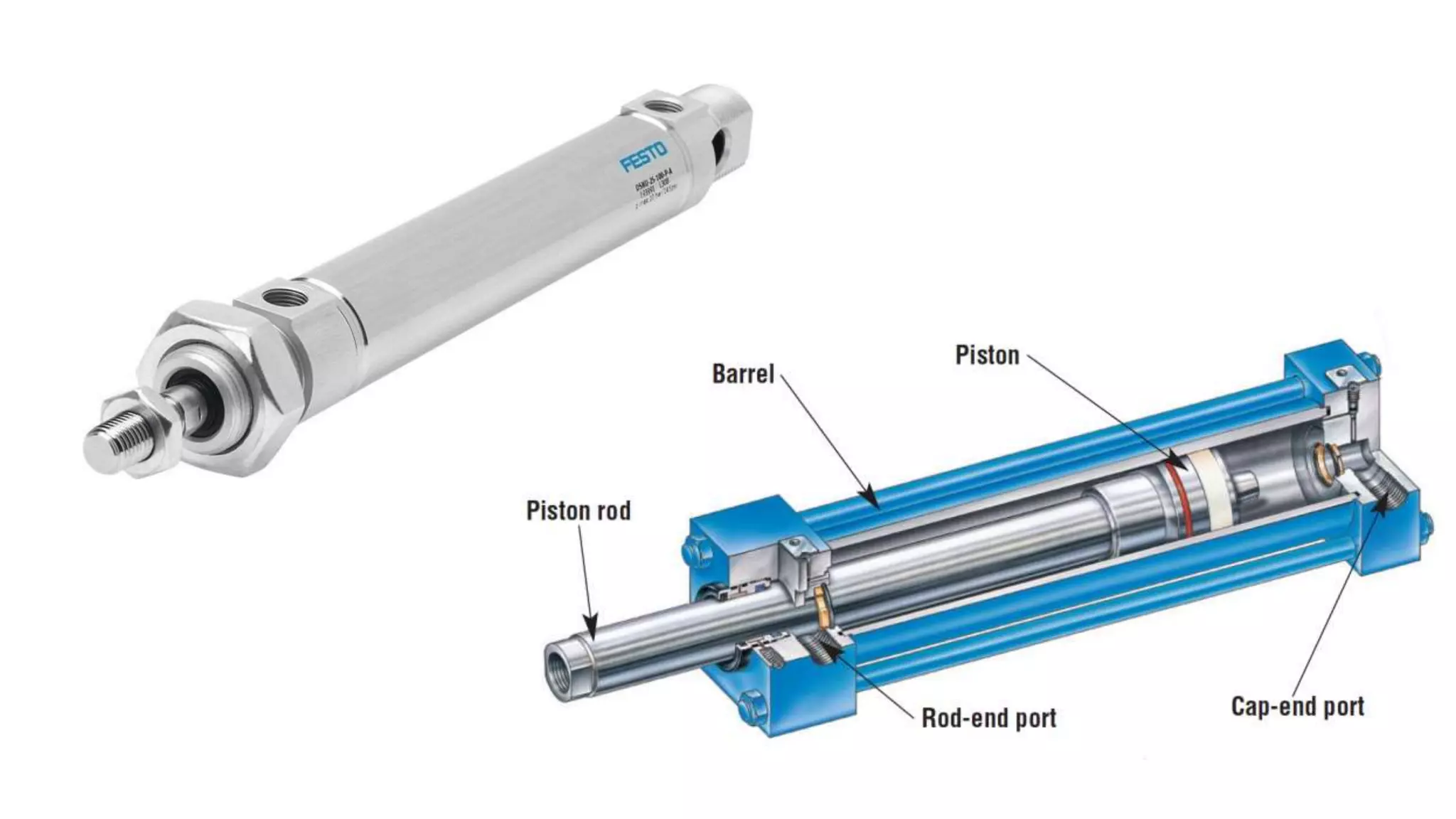

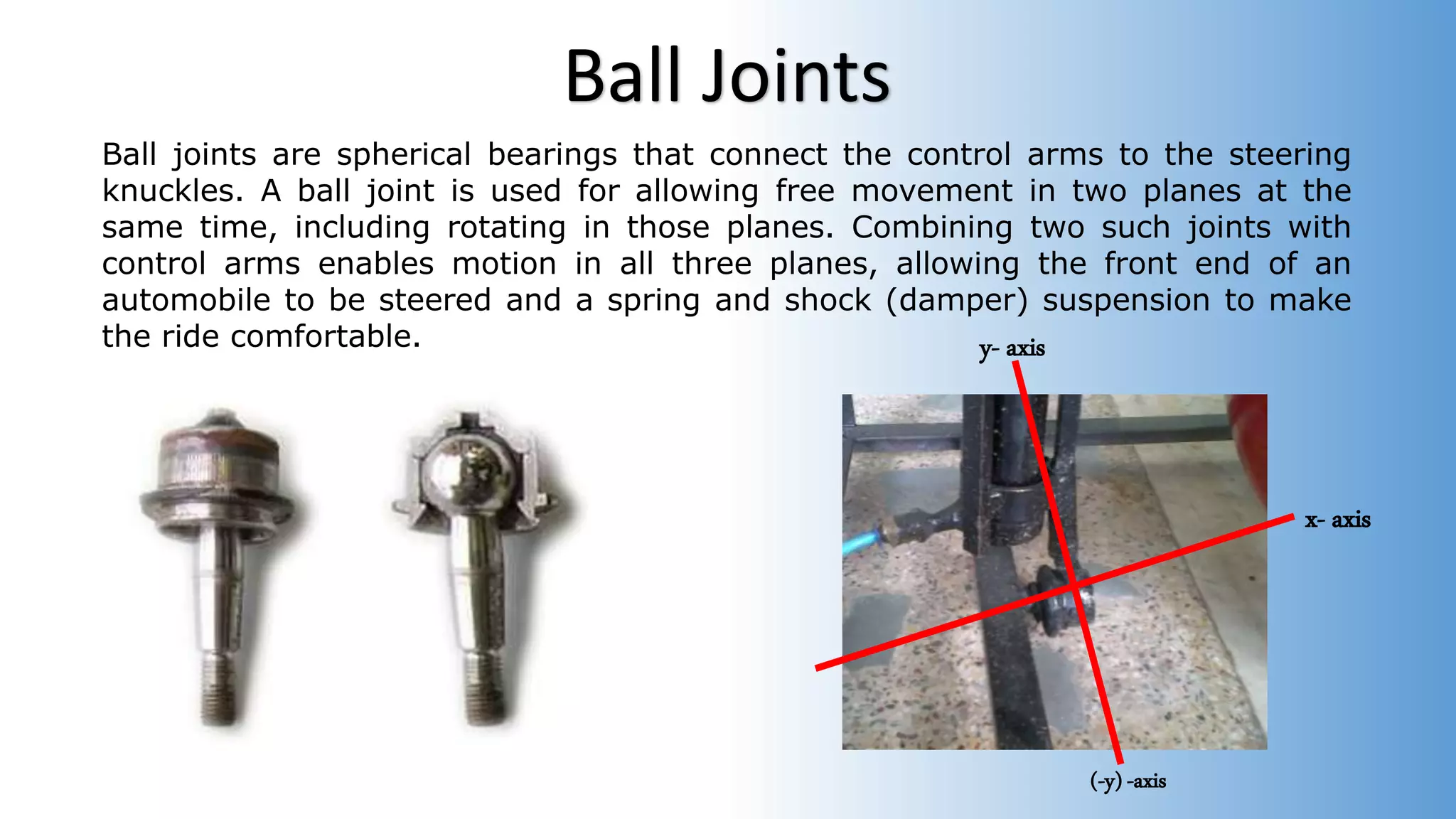

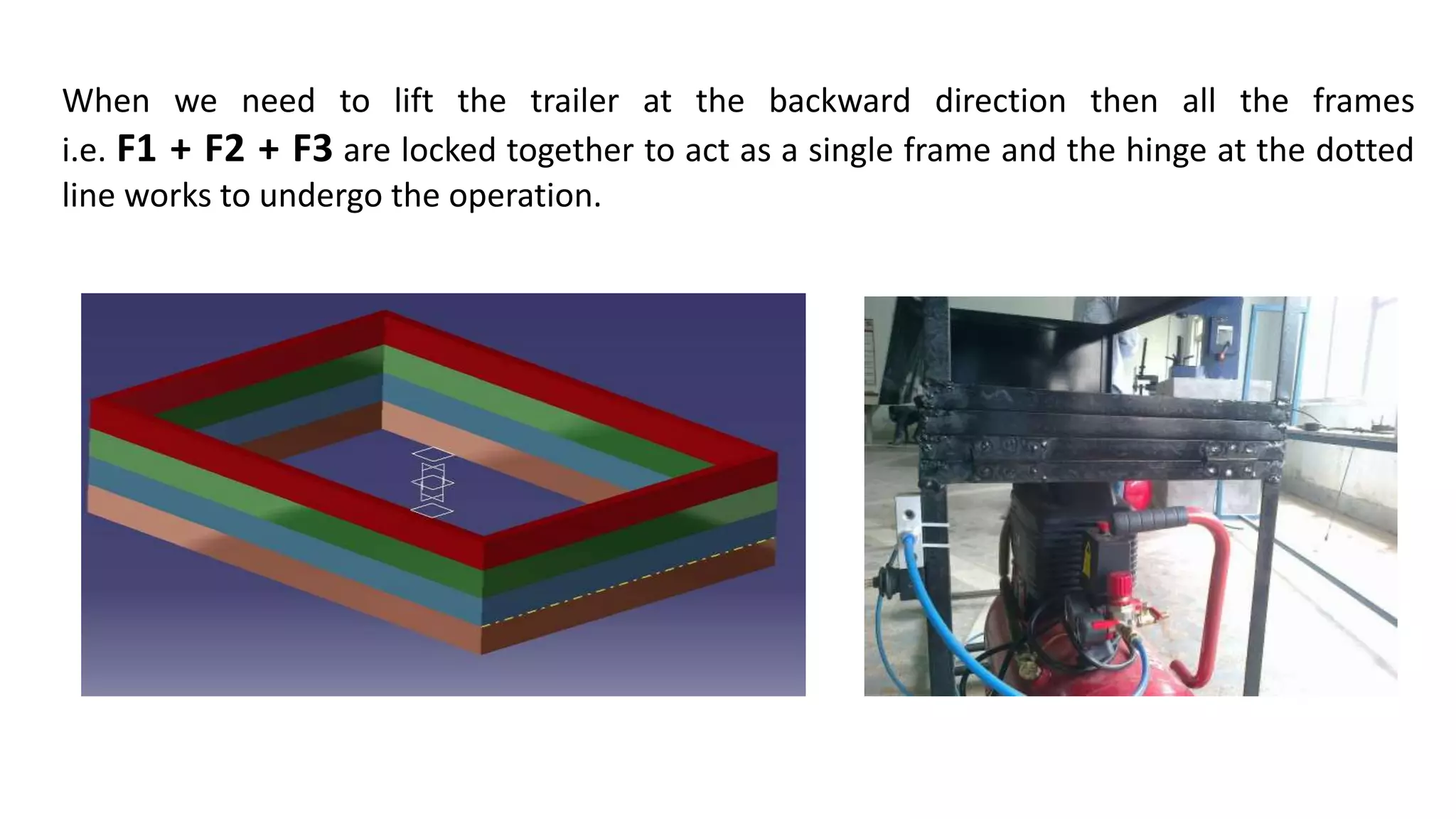

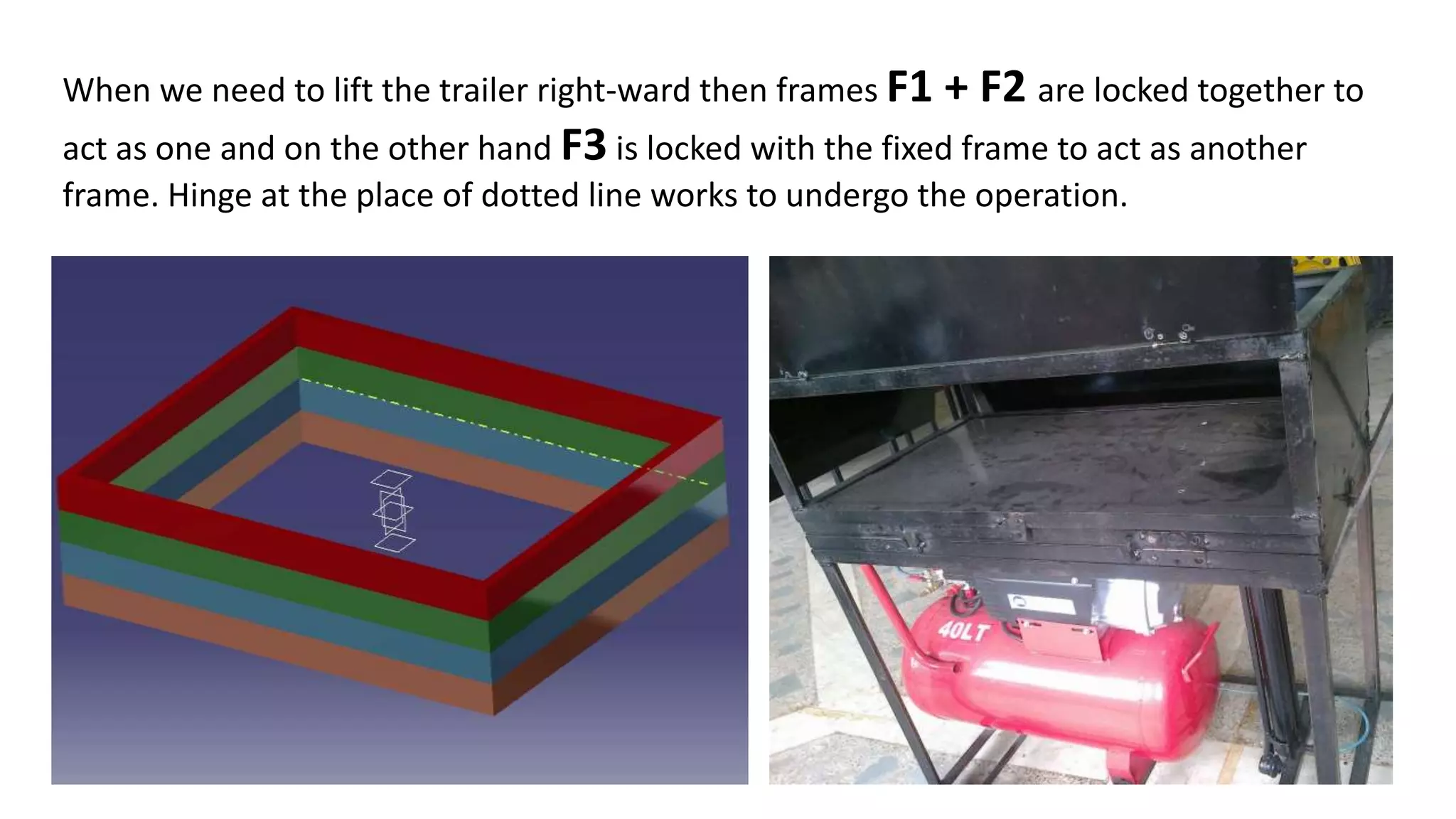

This document describes a 3-axis pneumatic trailer lifting system. The system uses pneumatically operated cylinders and control valves installed on a vehicle to lift the trailer in three directions - backwards, left, and right - for unloading goods in emergencies. It works by using compressed air and pneumatic cylinders to lift four interconnected frames that the trailer rests on, with the direction of lift determined by which frames are locked together. Key components include the base structure, air compressor, control valve, pneumatic cylinders, and trailer.