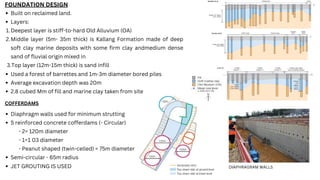

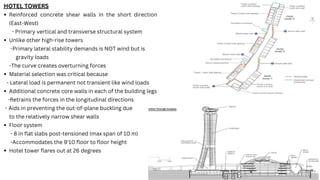

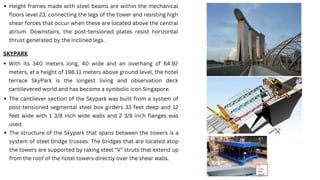

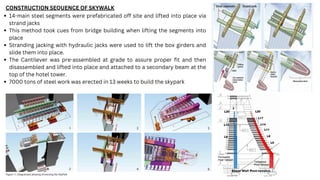

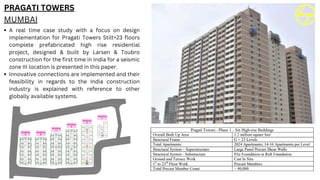

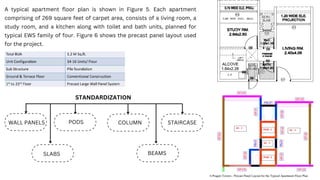

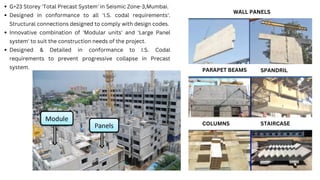

The Marina Bay Sands hotel in Singapore, completed in June 2010, features three towers, 57 stories high, and a distinctive sky park designed by Safdie Architects. The structural design incorporates reinforced concrete shear walls, post-tensioned slabs, and a unique cantilevered sky park, showcasing advanced engineering techniques. Additionally, Pragati Towers in Mumbai demonstrates the application of innovative precast construction methods for high-rise residential buildings in a seismic zone.