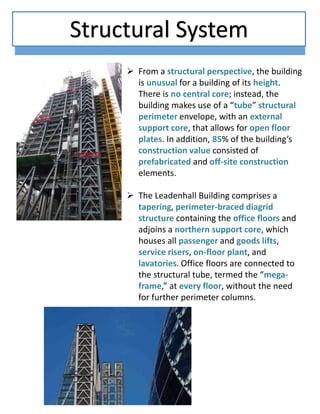

The Leadenhall Building, also known as the Cheese Grater, is a 224-meter tall office tower located in London, constructed between 2011 and 2014. The building features a unique structural design with an external support core, allowing for open floor plates and prefabricated construction, and prioritizes sustainability through its triple-glazed façade and energy-efficient systems. It incorporates innovative fire protection and mechanical systems while achieving significant construction waste diversion and local employment goals.