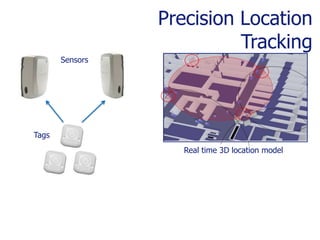

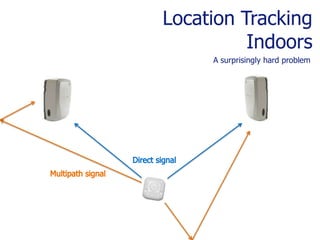

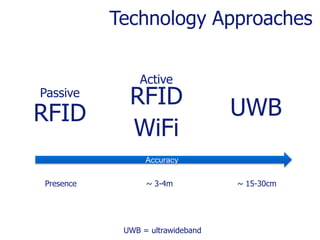

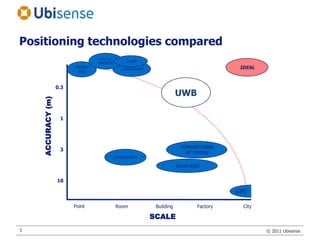

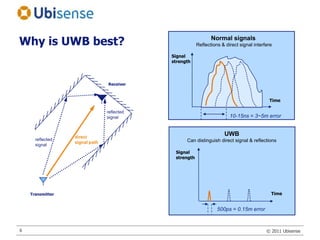

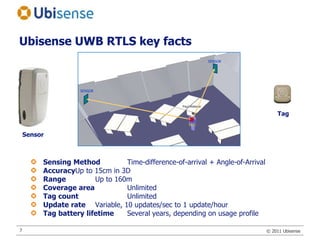

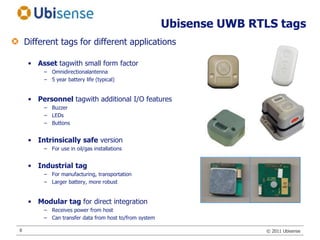

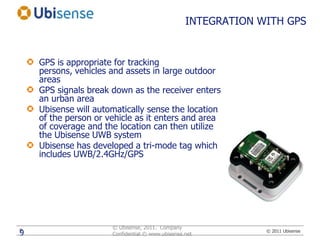

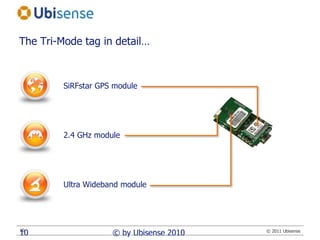

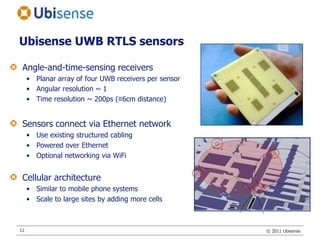

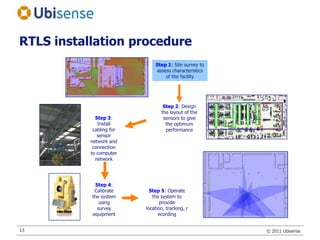

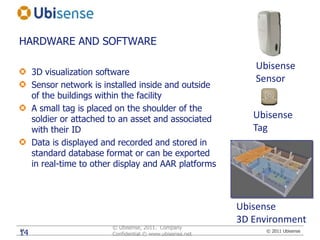

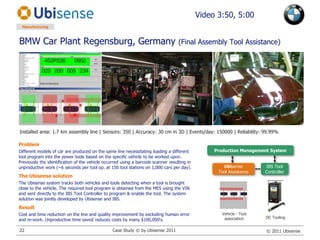

This document summarizes an indoor real-time location system (RTLS) using ultrawideband (UWB) technology. It can track tags with 15cm accuracy. The system uses sensors to detect time-of-arrival of UWB signals from tags to determine precise 3D locations. Example applications discussed include tracking assets in manufacturing plants and ports with accuracy better than WiFi and RFID. The system has also been used to track soldiers in military training exercises, track vehicles and tools at BMW, and monitor dairy cows on farms.