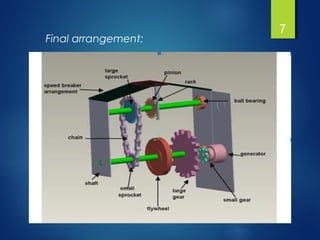

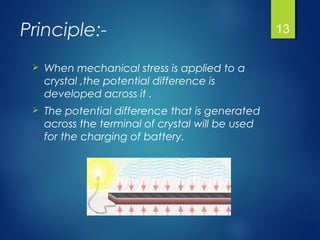

The document discusses methods for generating electricity using vehicle weight, aiming to alleviate the electricity crisis in India. Two key methods are explored: the rack-pinion mechanism and piezoelectric materials, both offering economic advantages and high efficiency. The paper concludes that these innovations could reduce dependency on traditional power sources and meet increasing energy demands.