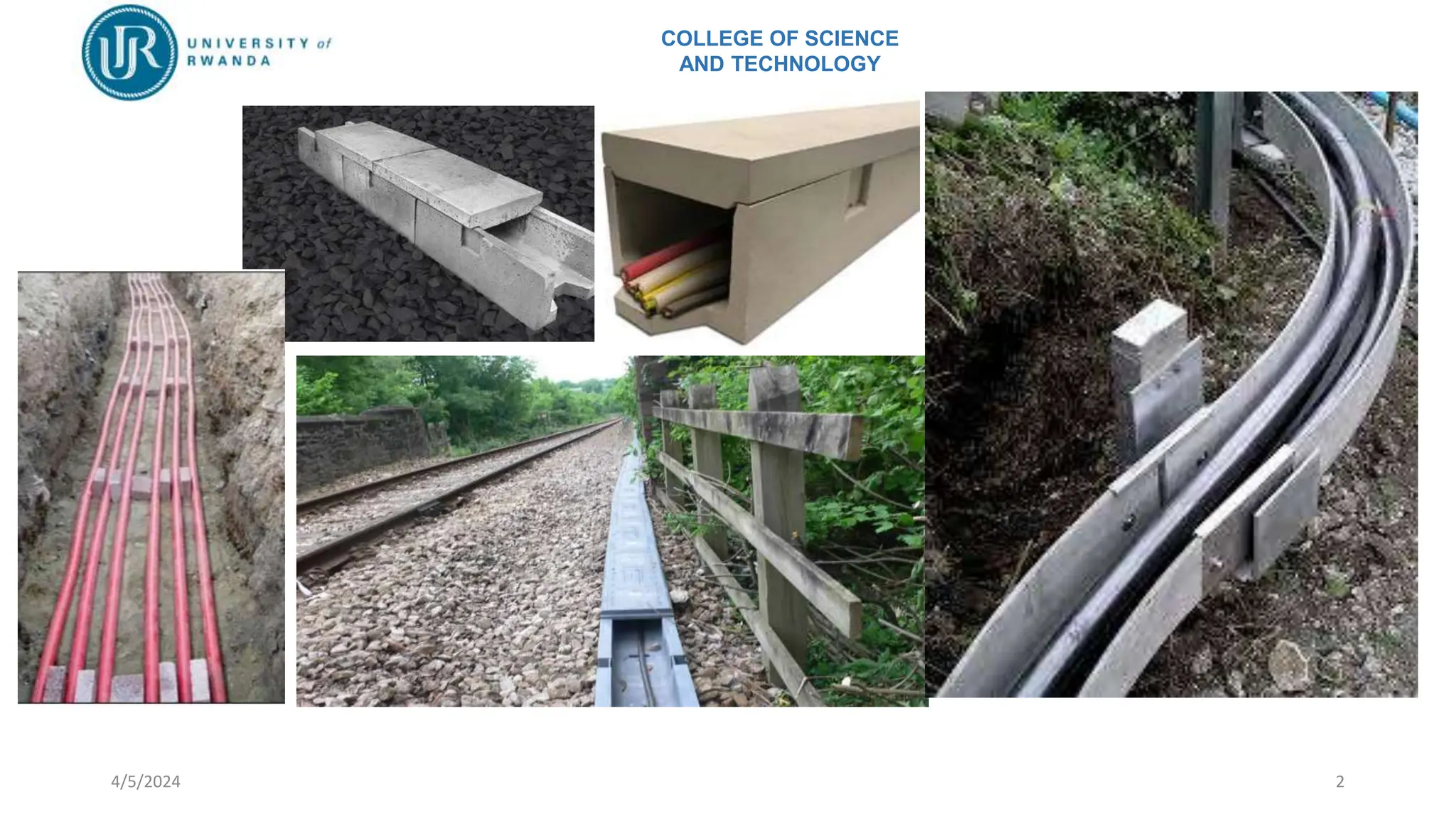

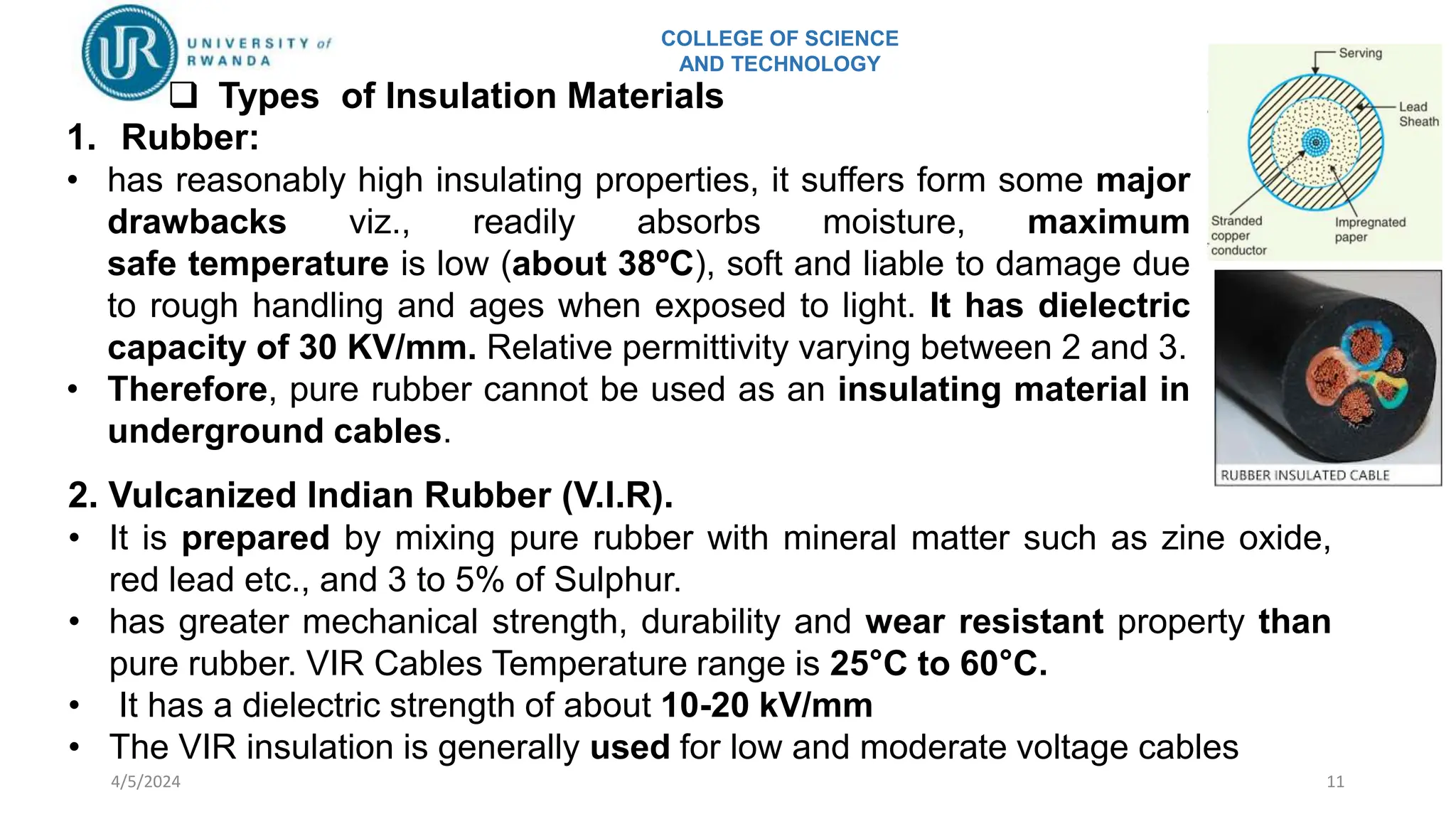

The document discusses the principles and applications of underground transmission lines and cables, including their construction, types, and requirements. It elaborates on the various insulating materials, cable classifications based on voltage and core configurations, as well as installation methods. The information emphasizes the significance of selecting appropriate cables for different electrical systems and environmental conditions, particularly in urban areas where overhead lines are impractical.

![COLLEGE OF SCIENCE

AND TECHNOLOGY

4/5/2024 48

These electrostatic fields give rise to core-core capacitances Cc and conductor-

earth capacitances Ce as shown in Fig. (ii).

The three Cc are delta connected whereas the three Ce are star connected, the

sheath forming the star point [See Fig. (iii)].](https://image.slidesharecdn.com/undergroundofelectricalpowersystem-240405131324-54d5a857/75/underground-of-electrical-power-system-pptx-48-2048.jpg)

![COLLEGE OF SCIENCE

AND TECHNOLOGY

4/5/2024 49

They lay of a belted cable makes it reasonable to assume equality of each Cc and

each Ce. The three delta connected capacitances Cc [See Fig. (i)] can be

converted into equivalent star connected capacitances as shown in Fig. (ii). It can

be easily shown that equivalent star capacitance Ceq is equal to three times the

delta capacitance Cc i.e. Ceq = 3Cc.](https://image.slidesharecdn.com/undergroundofelectricalpowersystem-240405131324-54d5a857/75/underground-of-electrical-power-system-pptx-49-2048.jpg)

![COLLEGE OF SCIENCE

AND TECHNOLOGY

4/5/2024 50

The system of capacitances shown in Fig. (iii)

reduces to the equivalent circuit shown in

Fig. (i). Therefore, the whole cable is

equivalent to three star-connected

capacitors each of capacitance [See Fig. (ii)]](https://image.slidesharecdn.com/undergroundofelectricalpowersystem-240405131324-54d5a857/75/underground-of-electrical-power-system-pptx-50-2048.jpg)