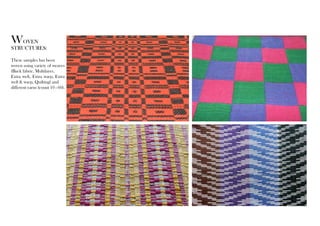

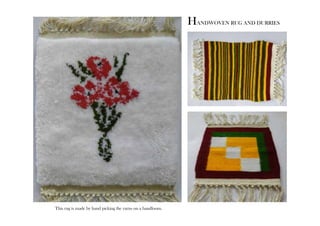

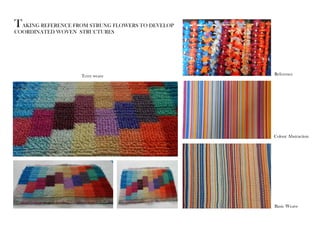

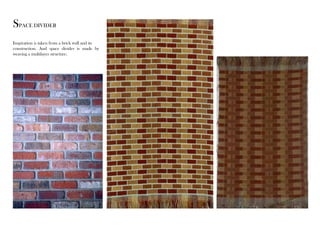

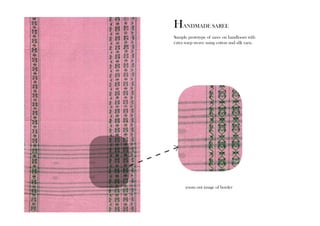

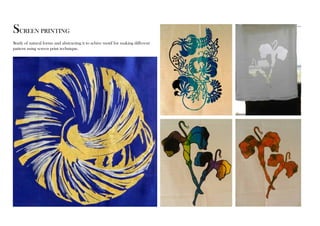

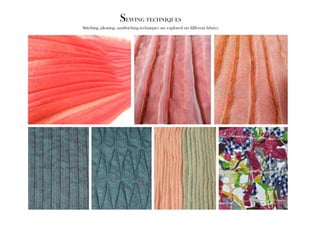

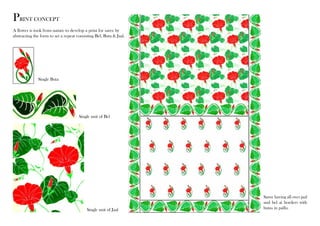

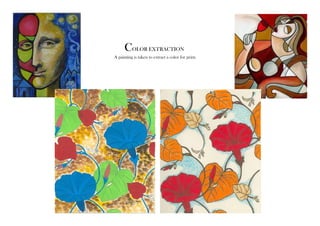

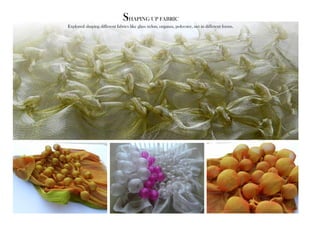

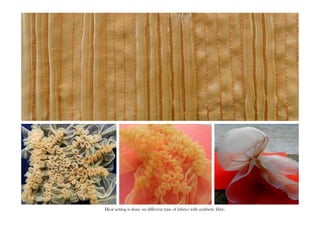

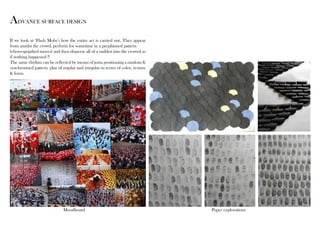

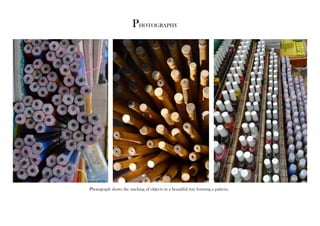

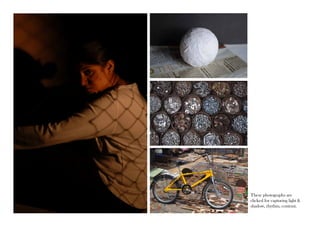

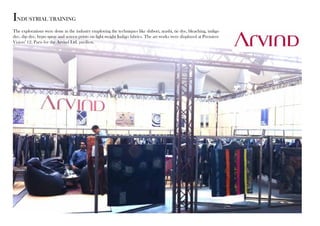

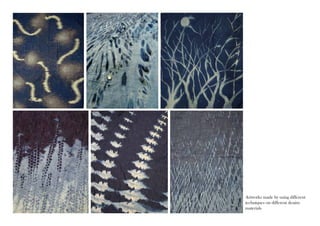

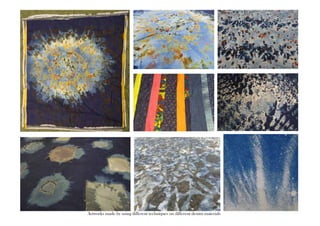

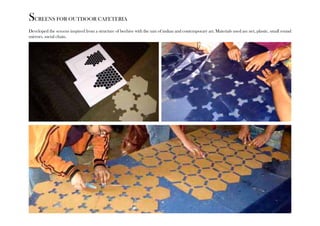

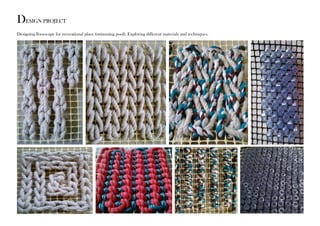

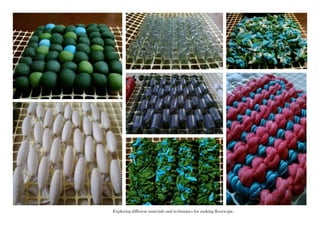

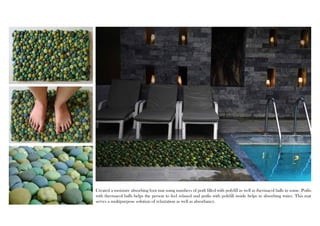

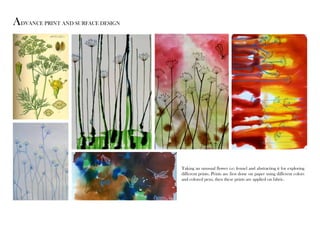

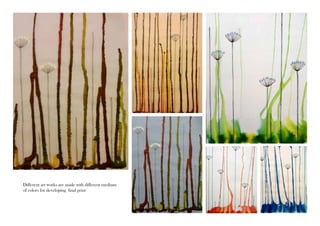

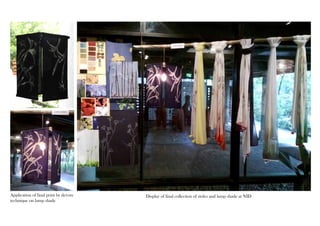

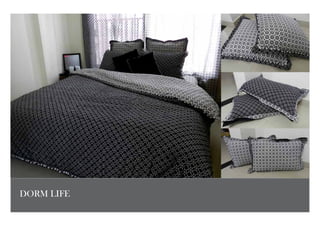

This document contains the resume of Monika Bairwa, who has studied textile design at the National Institute of Design in Ahmedabad. It outlines her education in textile weaving and design, as well as her skills and experience in areas such as weaving, printing, embroidery, and garment design. It also provides examples of her past projects developing printed textiles, constructed textiles, and bedding collections for her diploma project.