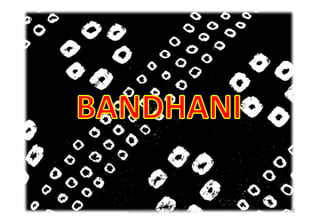

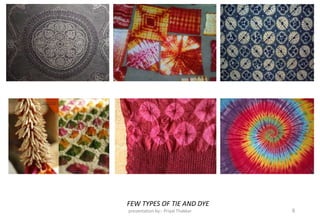

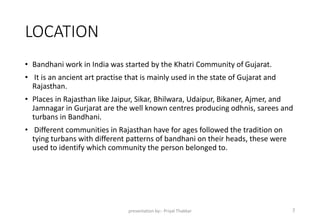

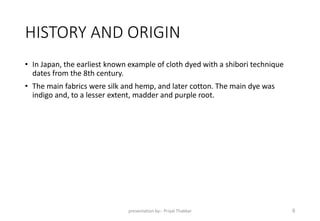

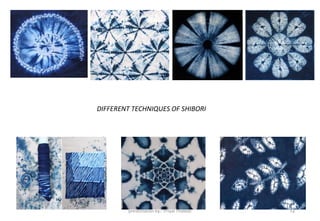

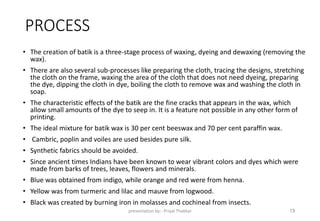

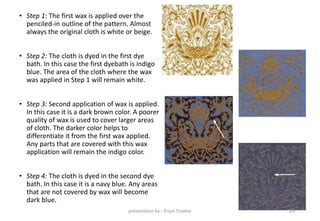

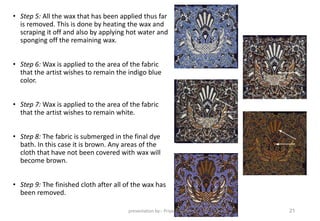

The document discusses the traditional dyeing techniques of bandhani, shibori, and batik, detailing their historical origins, processes, and regional significance in India and beyond. Bandhani, performed mainly by the Khatri community in Gujarat and Rajasthan, involves intricate knotting and dyeing to create various patterns. Shibori and batik are also described, focusing on their unique methods and cultural meanings across different locales, including Japan and Indonesia.