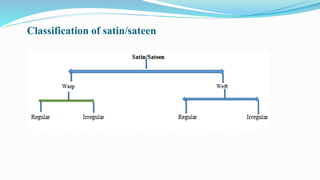

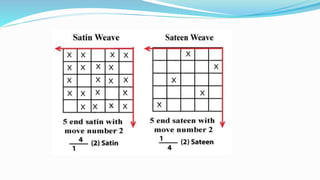

This document summarizes the key features of satin and sateen weaves. Satin weave produces a smooth, lustrous fabric surface when made with filament yarns like silk or nylon, while sateen weave uses short-staple yarns like cotton. Satin weave has a loose structure with only one warp or weft yarn interlacing at a time and long floats that cover interlacing points, producing no visible twill lines. Satin weave can be classified as warp satin if warp floats are prominent or weft satin/sateen if weft floats are prominent. The distance between interlacing points is called the move number or