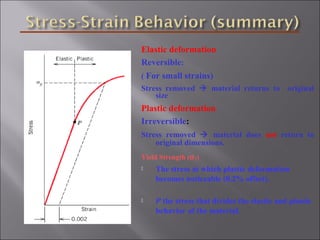

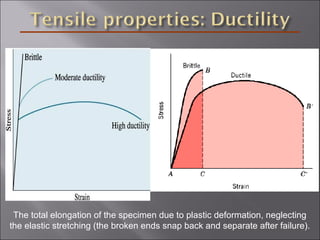

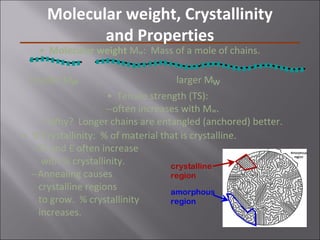

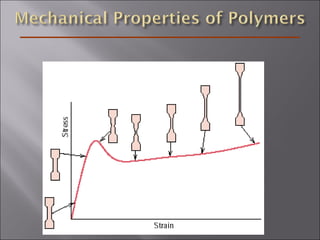

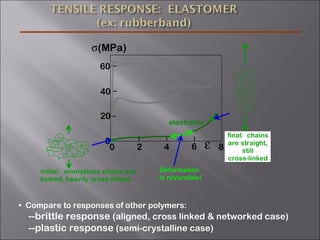

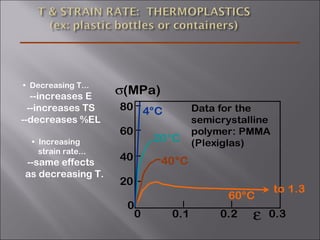

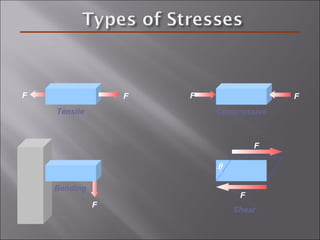

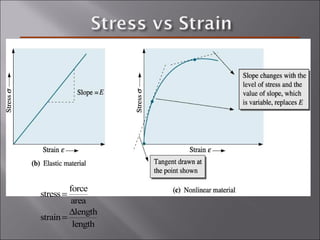

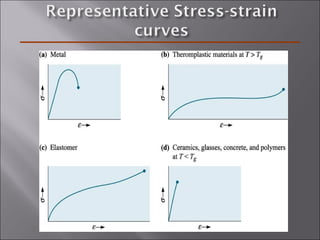

- Stress and strain are size-independent measures of load and displacement, respectively. Elastic behavior shows a linear stress-strain relation. Plastic behavior occurs when tensile stress reaches the yield strength (σy).

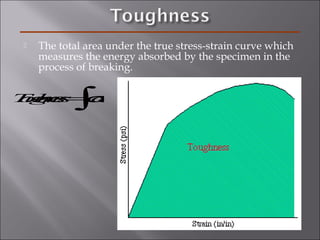

- The elastic modulus (E or G) and yield strength characterize mechanical properties. Materials with larger E resist deformation better. Toughness is the energy to break a material.

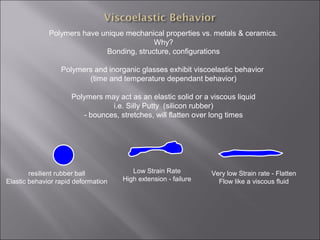

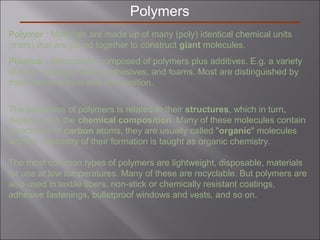

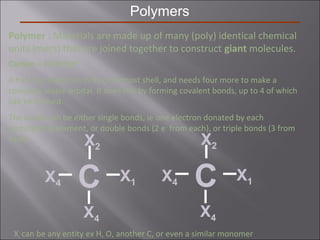

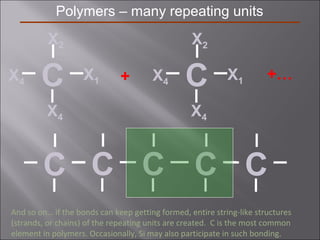

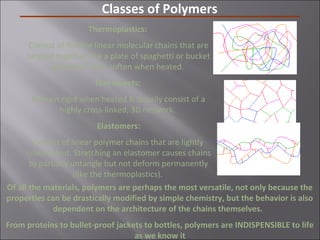

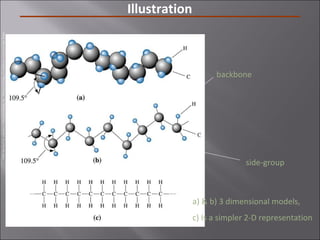

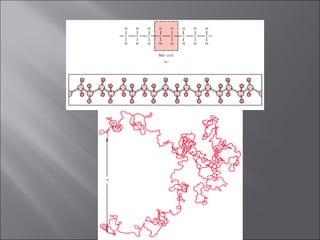

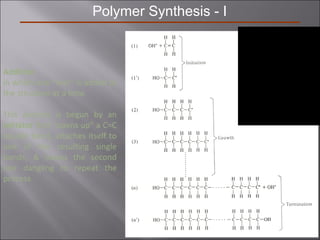

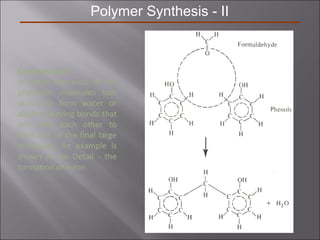

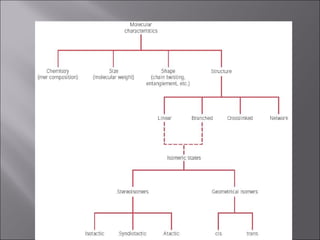

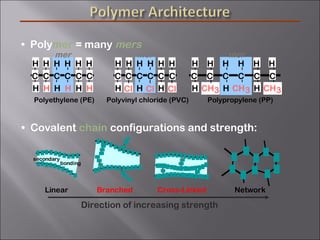

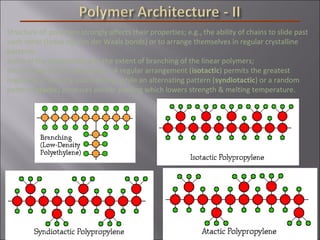

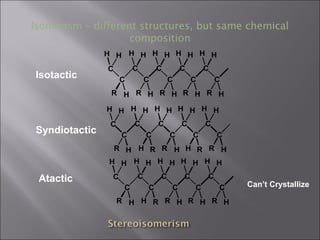

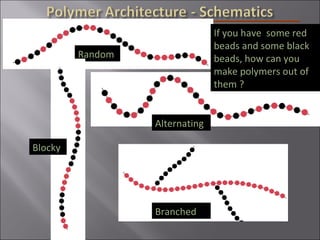

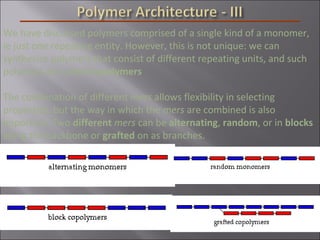

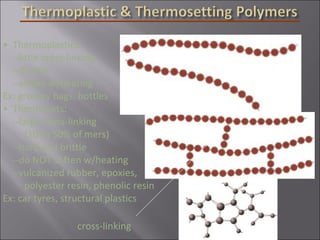

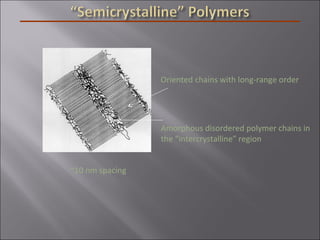

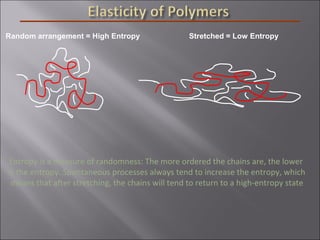

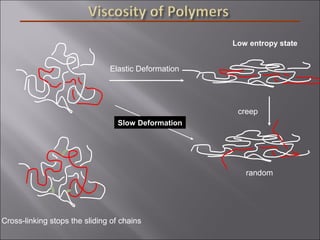

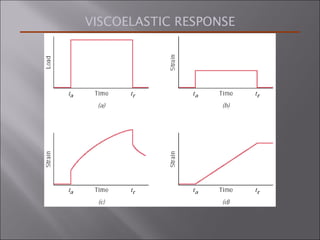

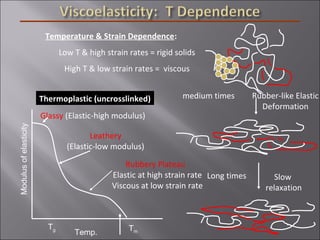

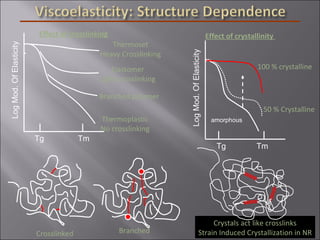

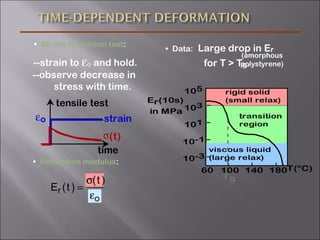

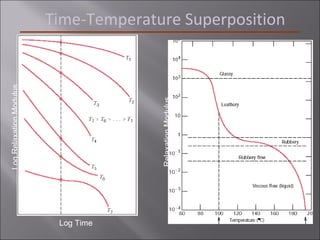

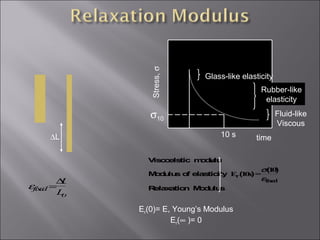

- Polymers have unique time- and temperature-dependent viscoelastic behavior compared to metals and ceramics. Their properties depend on bonding, structure, and chain configurations.

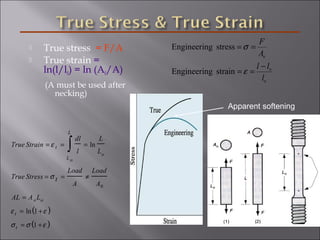

![ The slope of the stress-strain

curve in the elastic region.

Hooke’s law: E = σ/ε

A measure of the stiffness of

the material.

Larger the value of E, the

more resistant a material is to

deformation.

Note: ET = Eo – bTe-To/T

where Eo and b are empirical

constants, T and To are

temperatures

Units:

E: [GPa] or [psi]

ε : dimensionless](https://image.slidesharecdn.com/polymerproperties-170310073755/85/Polymer-properties-5-320.jpg)