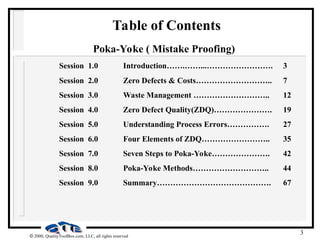

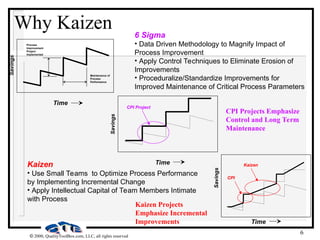

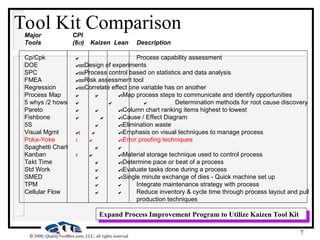

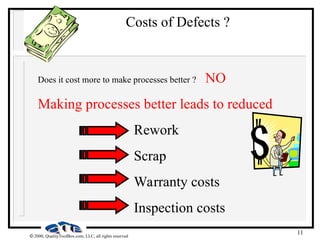

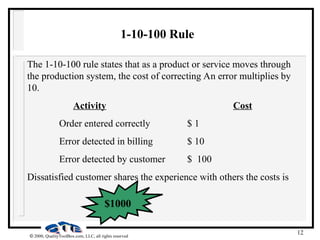

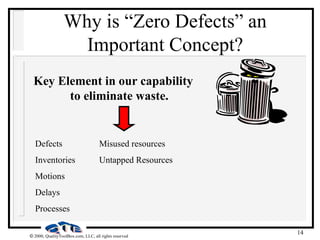

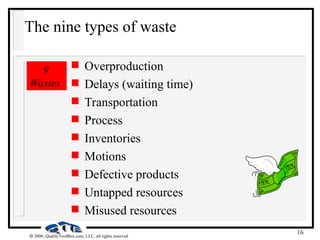

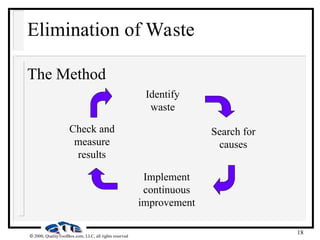

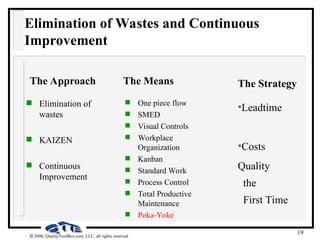

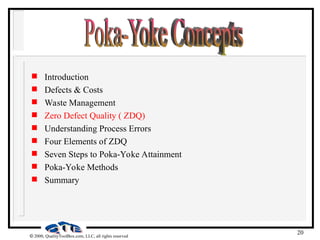

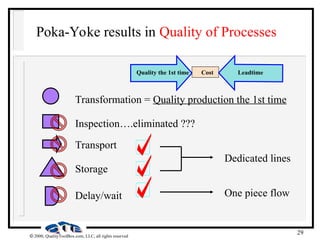

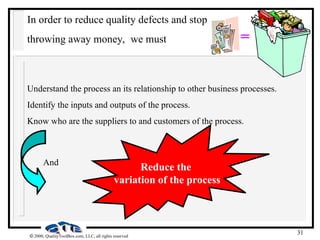

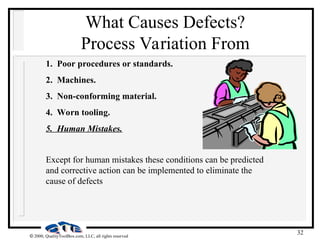

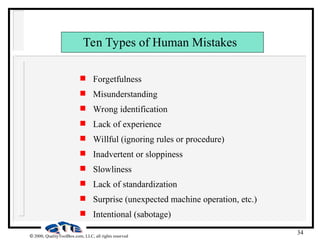

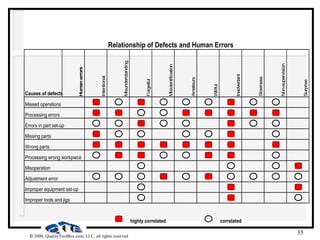

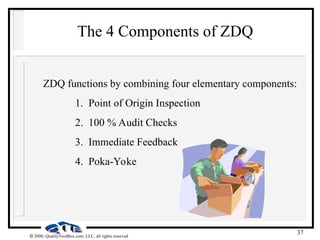

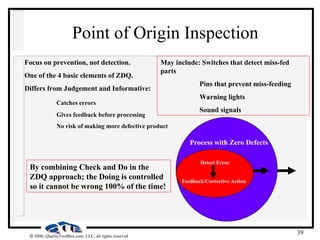

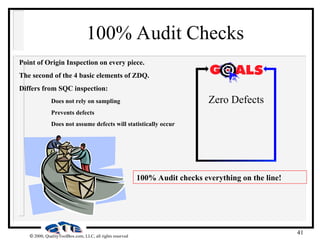

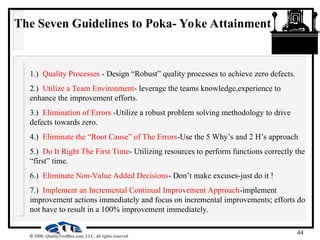

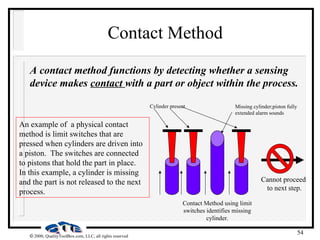

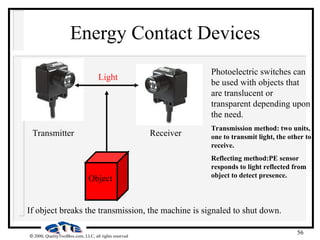

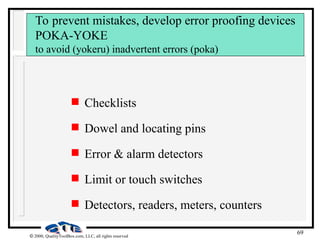

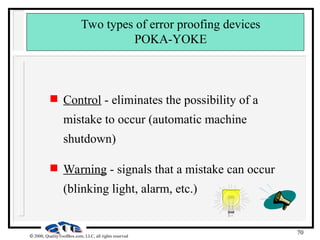

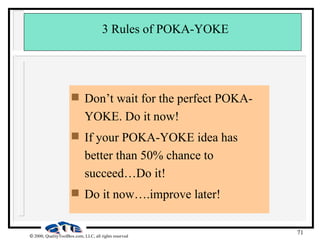

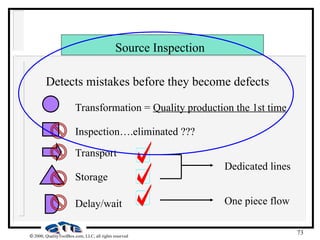

The document outlines a training module focused on achieving performance excellence through the concept of zero defects and waste management in manufacturing processes. It introduces key concepts such as mistake-proofing (poka-yoke) and continuous improvement methodologies like kaizen and six sigma, emphasizing the need for a disciplined approach in eliminating defects and enhancing quality. Various tools and strategies are discussed, including the importance of understanding process variations and the implementation of effective inspection techniques to prevent defects before they occur.