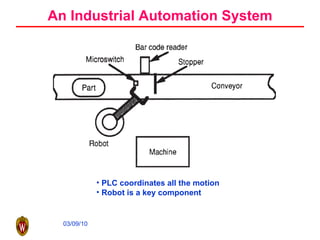

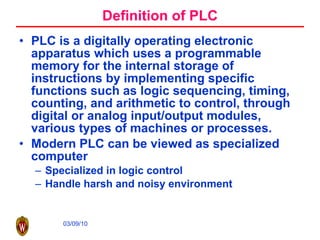

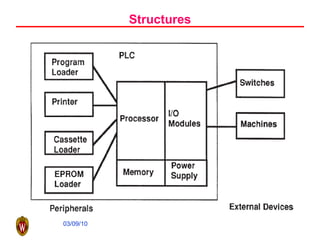

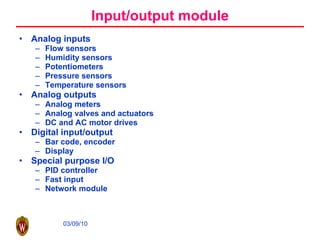

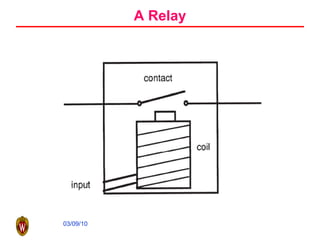

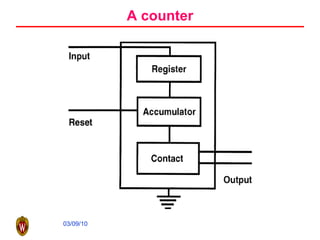

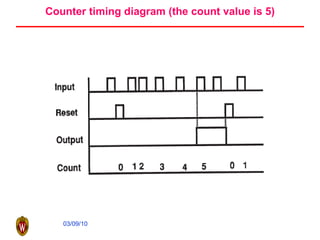

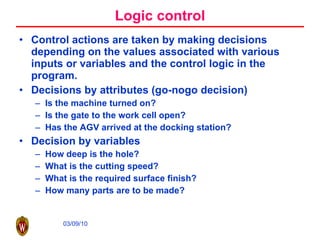

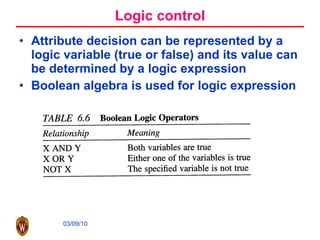

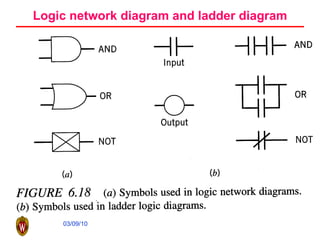

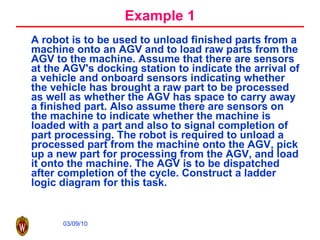

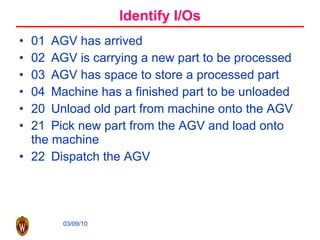

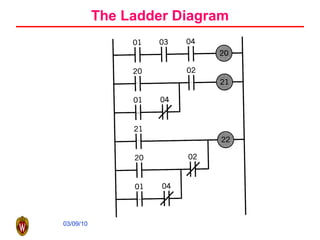

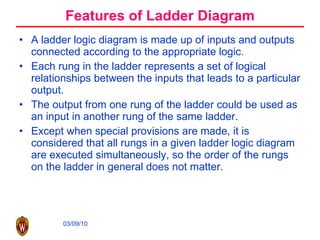

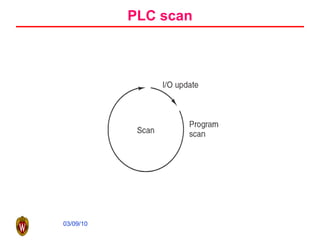

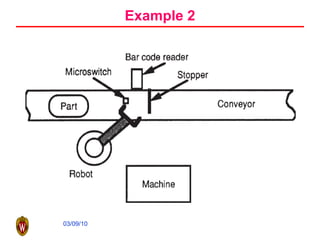

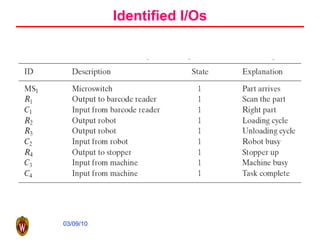

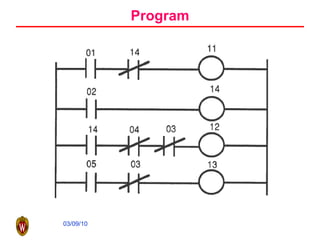

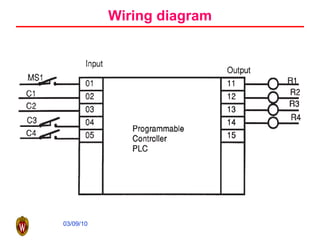

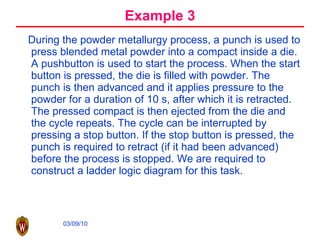

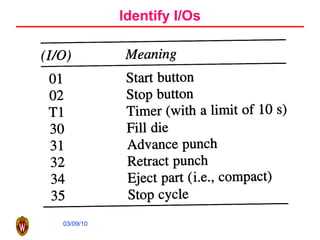

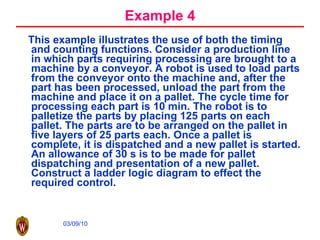

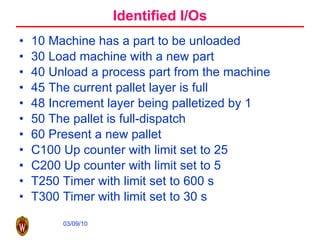

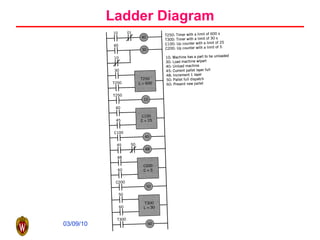

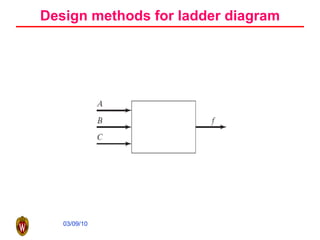

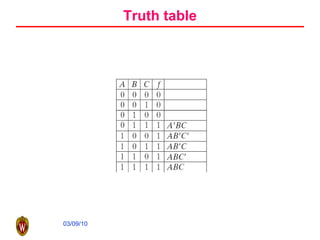

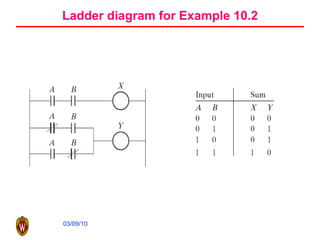

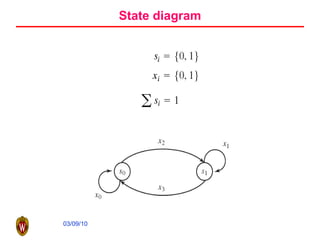

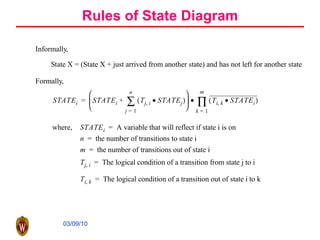

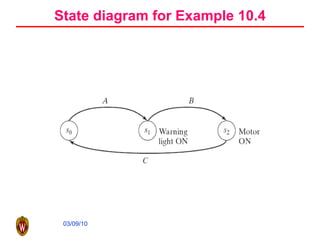

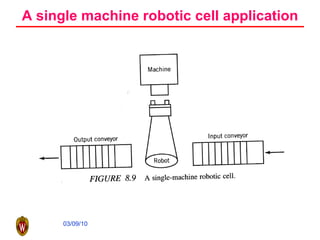

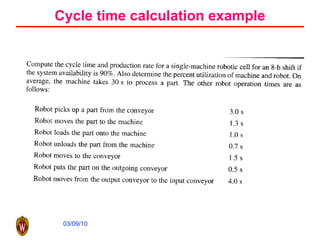

The document discusses programmable logic controllers (PLCs) and industrial robots. It defines PLCs as digitally operating electronic devices that use programmable memory to implement logic functions to control machines and processes. PLCs have input/output modules, memory, and peripherals. The document also discusses ladder logic diagrams used to program PLCs to control sequences like having a robot unload parts from one machine and load parts into another machine.