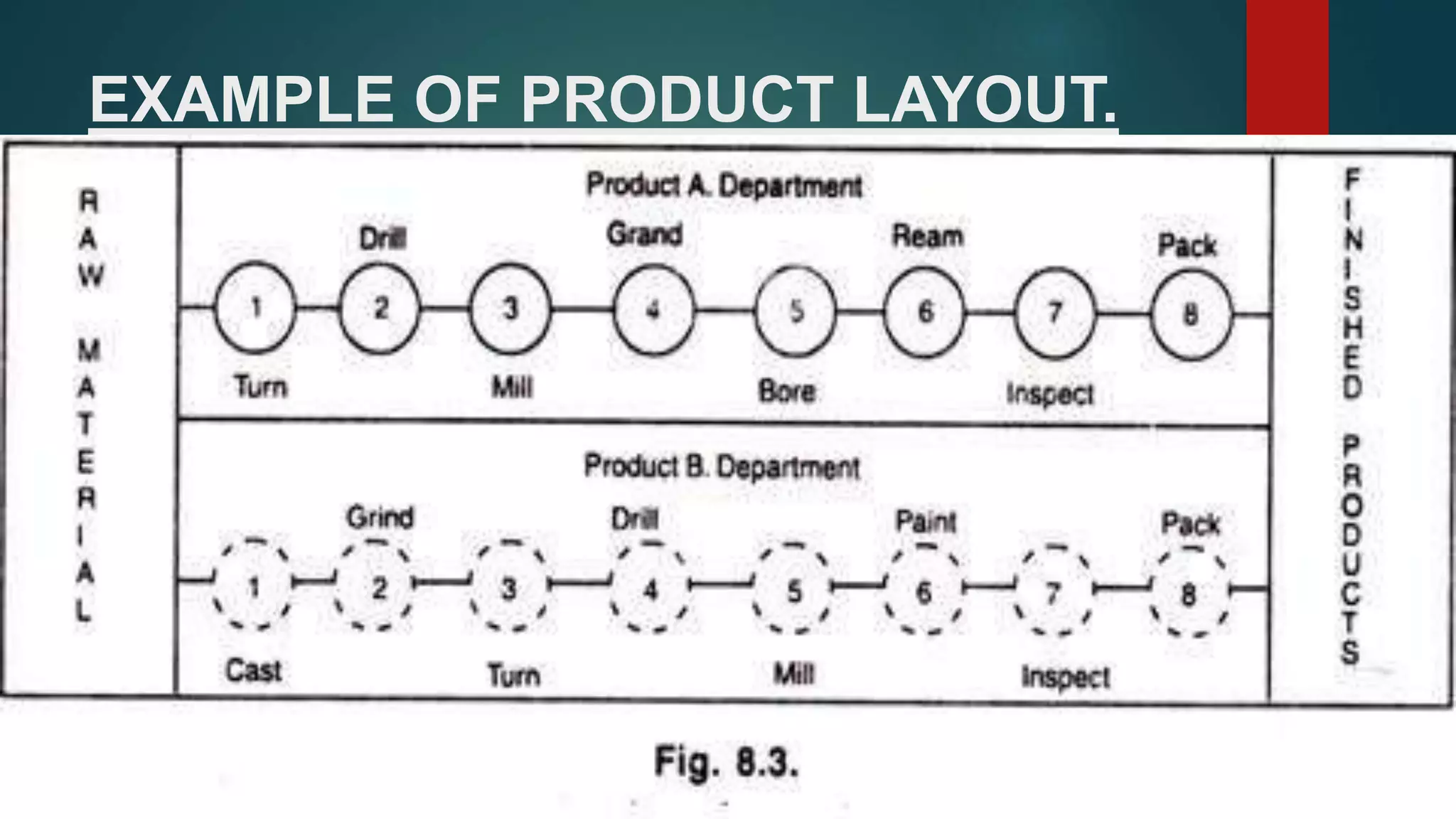

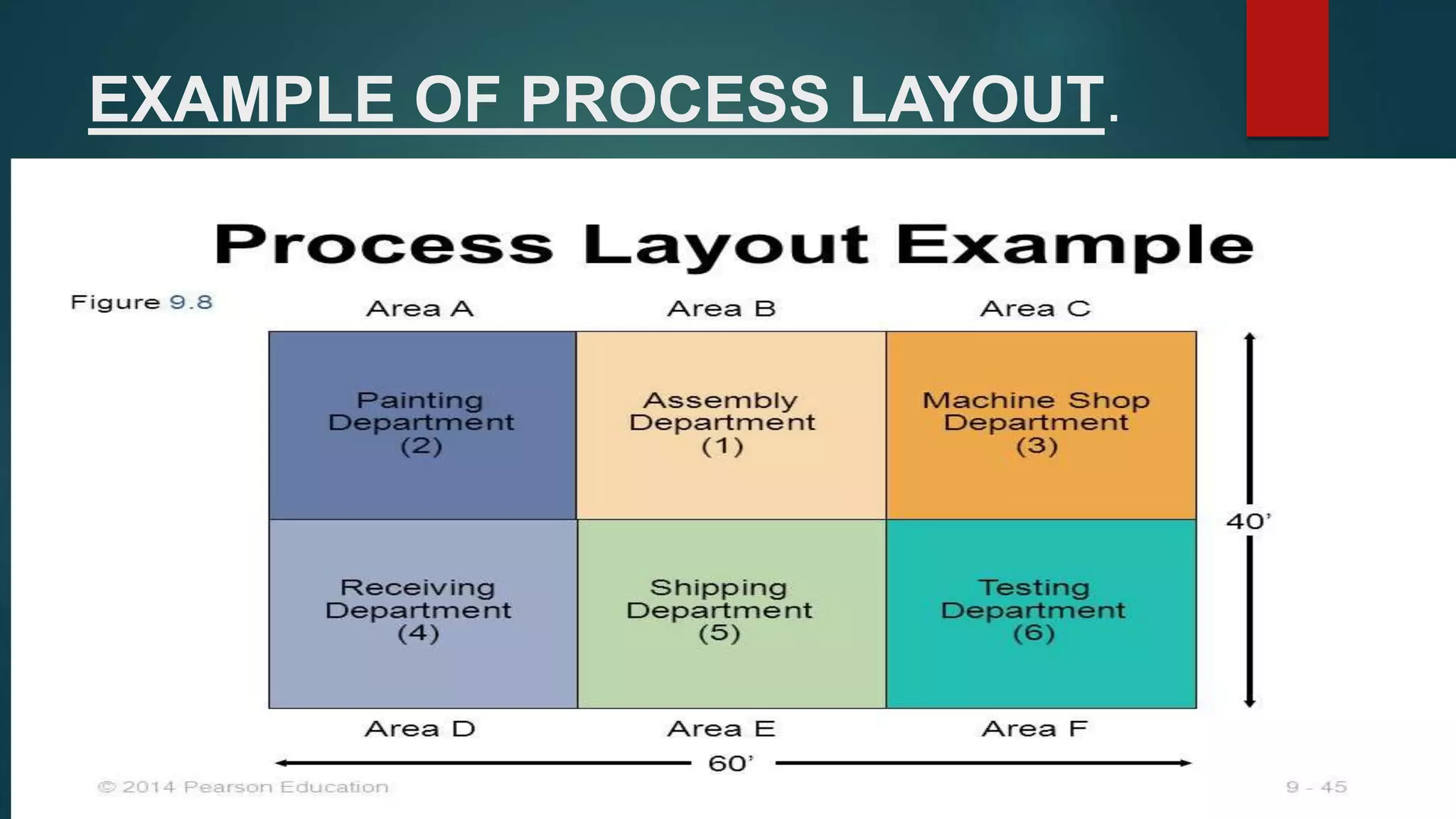

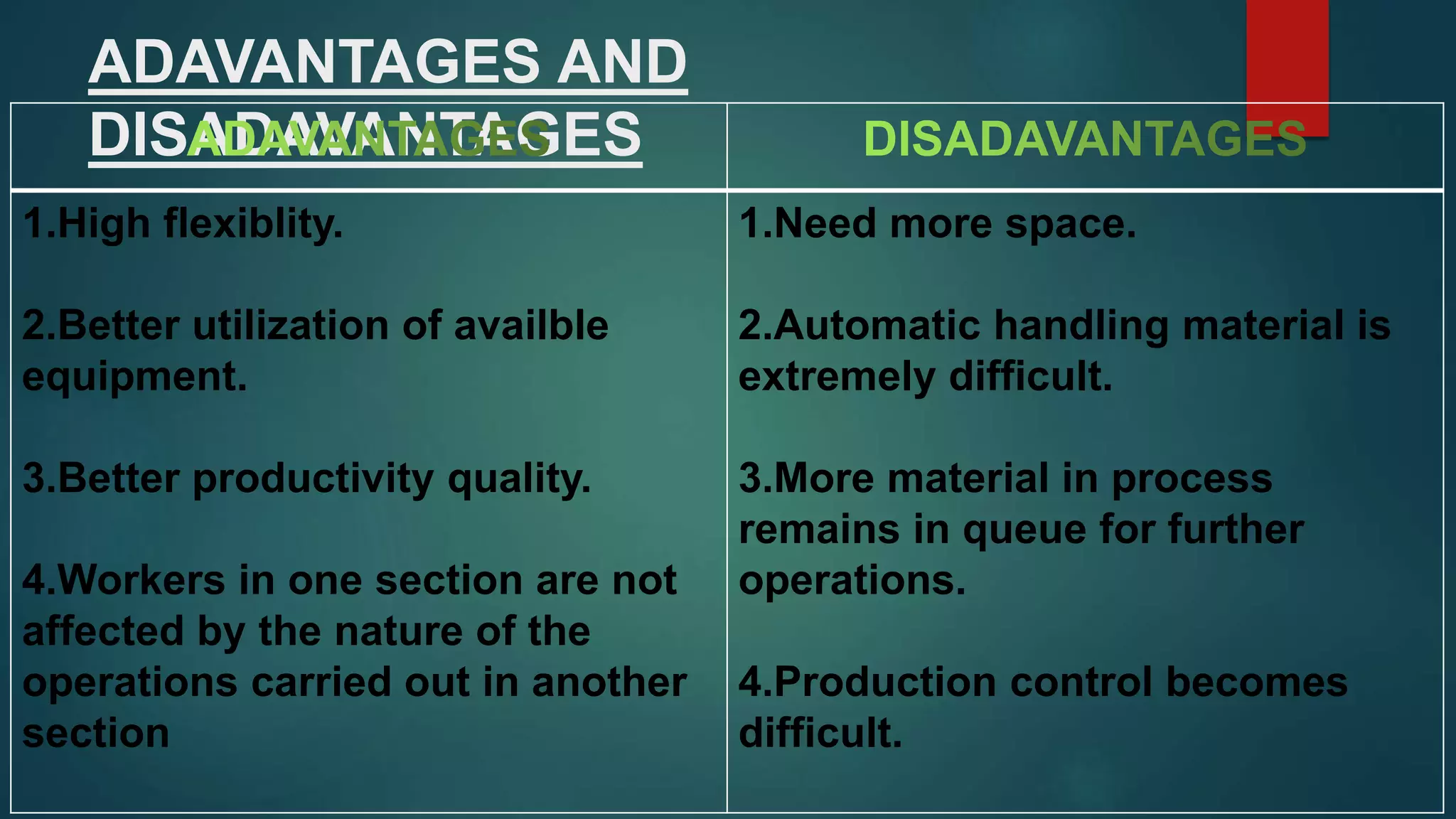

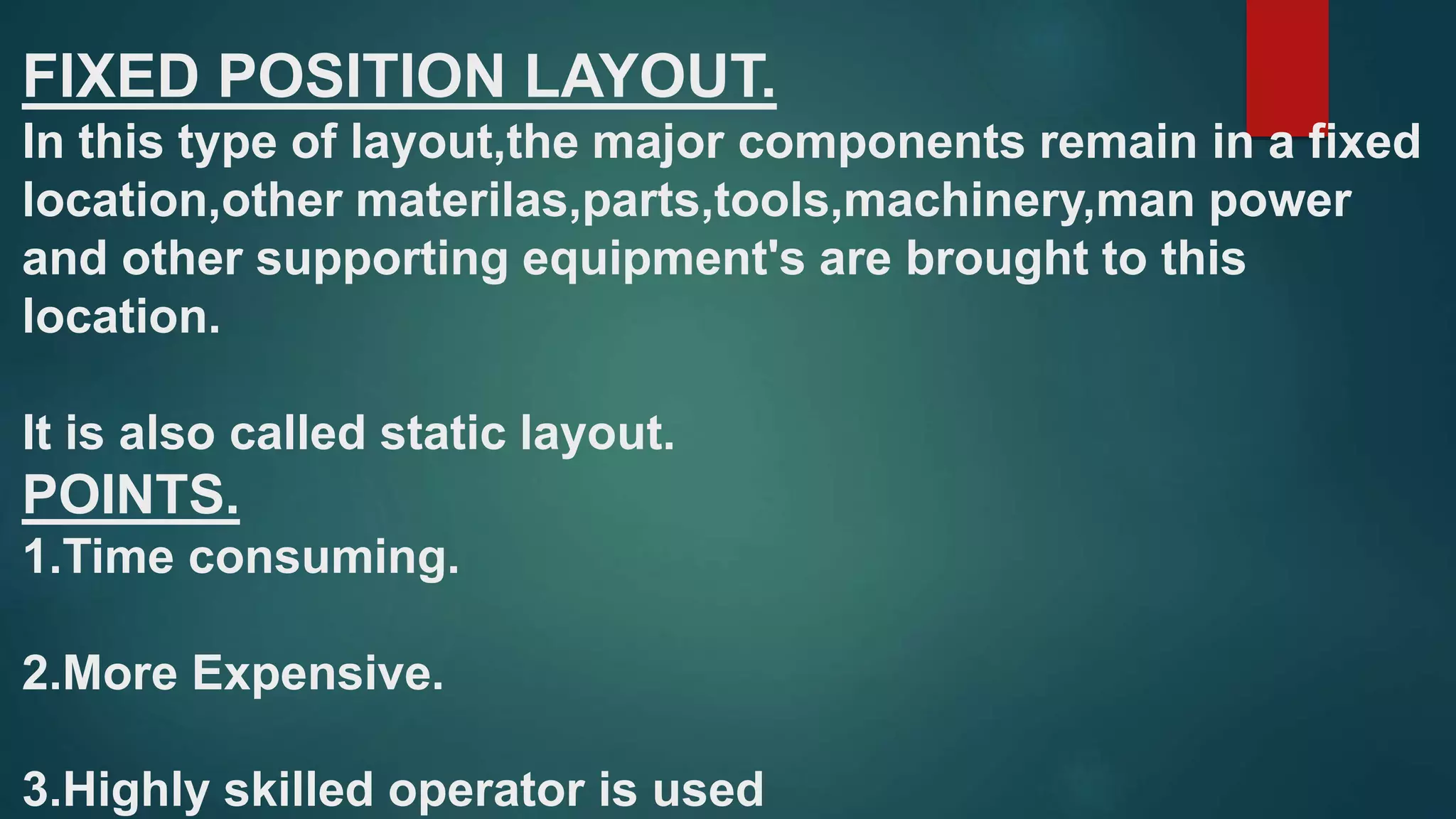

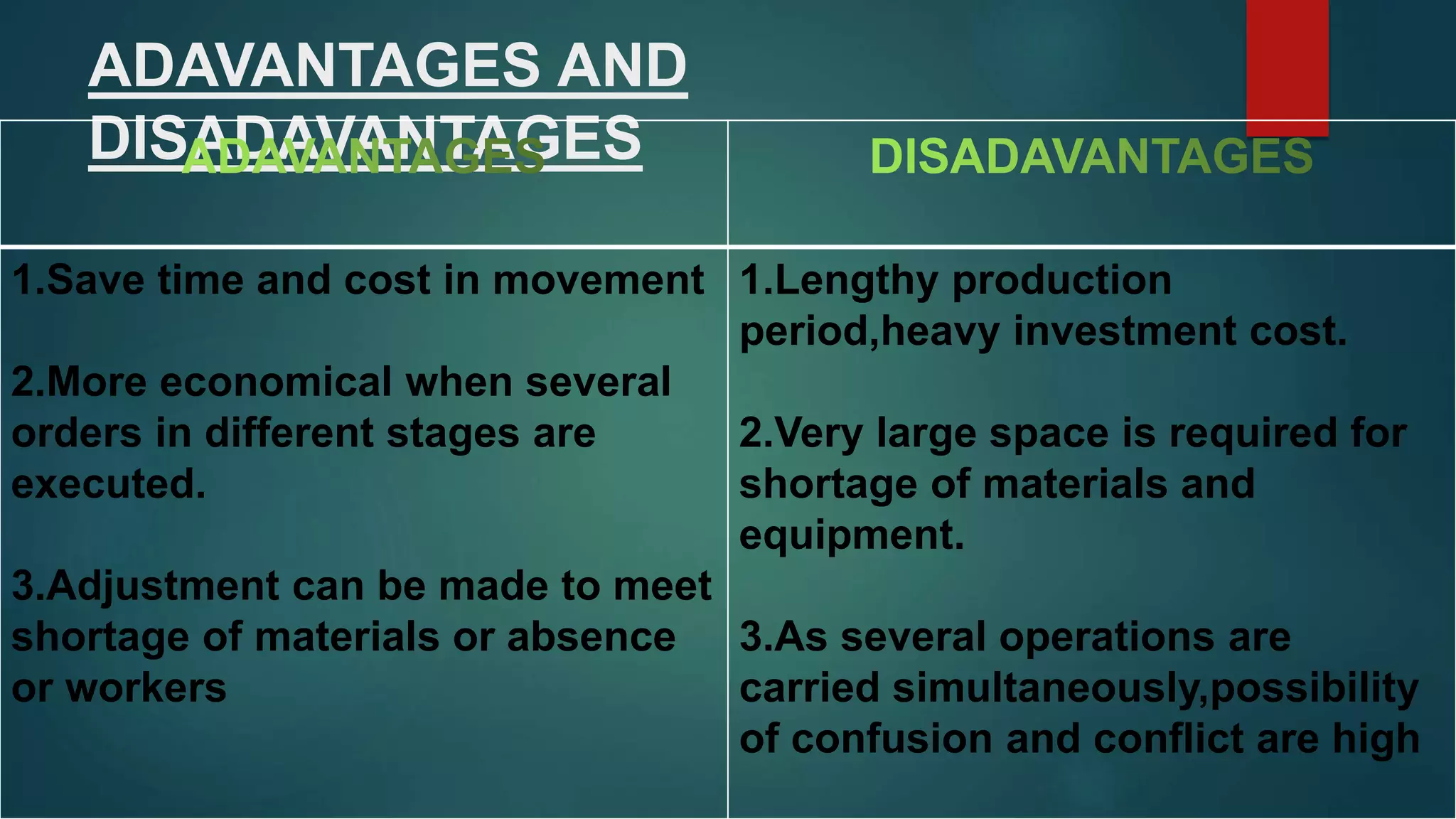

This document discusses four main types of plant layouts: product layout, process layout, fixed layout, and combined or group layout. It provides definitions and examples of each layout type along with their advantages and disadvantages. A product layout arranges equipment by the sequence of operations for a product. A process layout groups similar machines together regardless of the product sequence. A fixed layout keeps major components stationary while bringing other materials and tools to them. A combined layout uses elements of the other layouts to provide flexibility for industry requirements.