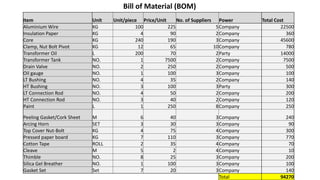

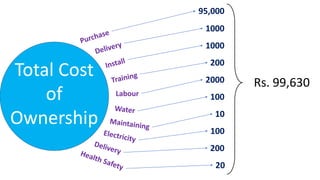

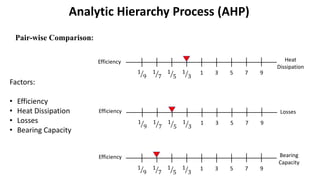

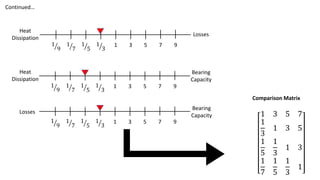

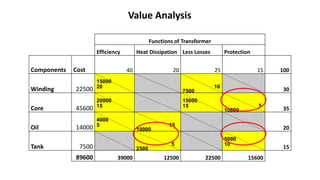

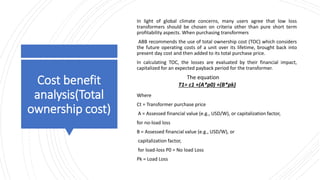

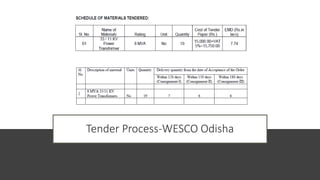

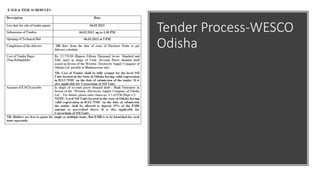

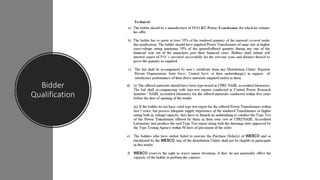

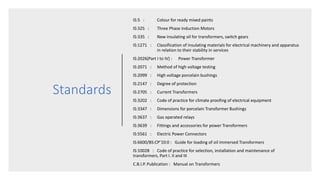

The document provides a detailed procurement plan for transformer components, including a bill of materials and cost analysis. It emphasizes the importance of low-loss transformers for reducing operating costs and environmental impact. Additionally, it outlines the tender process and relevant standards for supplier qualifications and materials.