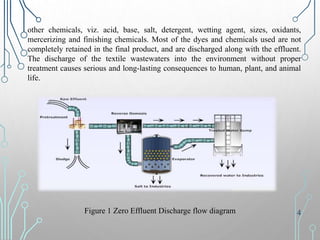

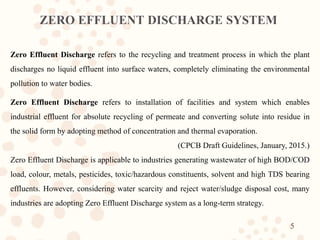

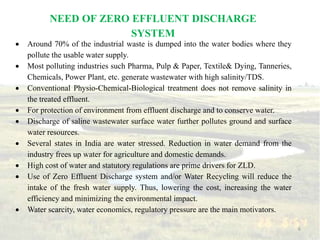

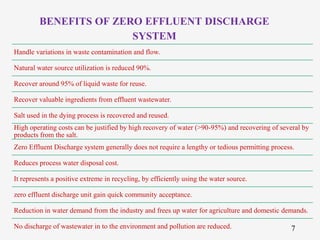

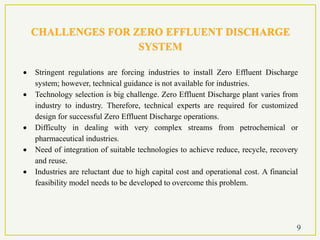

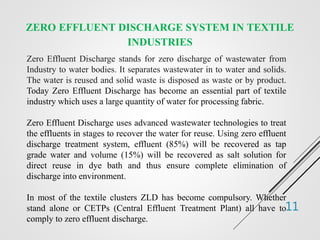

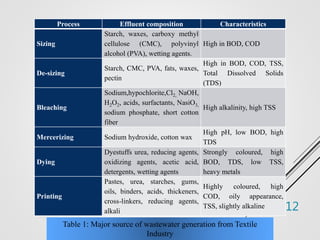

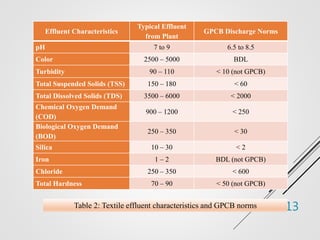

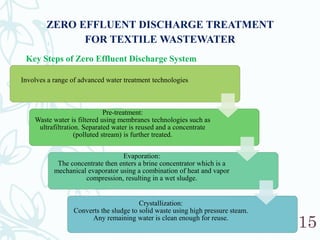

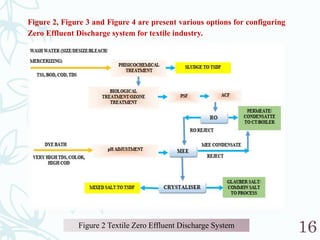

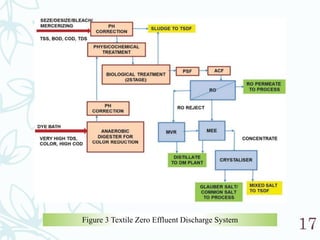

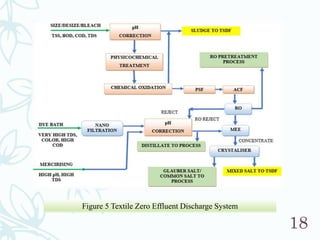

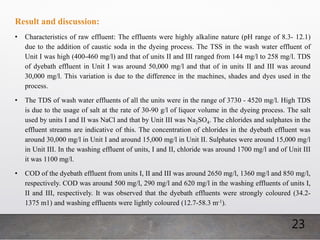

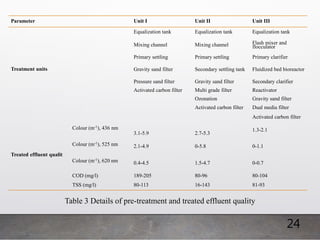

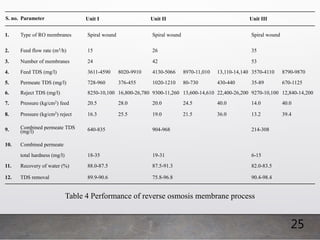

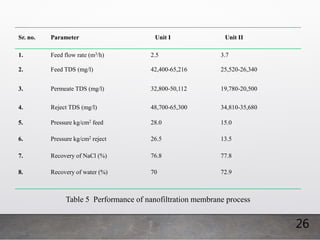

The document discusses zero effluent discharge systems. It provides an introduction and overview of zero effluent discharge, including the need for such systems, their benefits, drivers and challenges. It then discusses specific applications for zero effluent discharge in industries like textiles. The document focuses on zero effluent discharge treatment of textile wastewater, outlining the key treatment steps and environmental challenges.