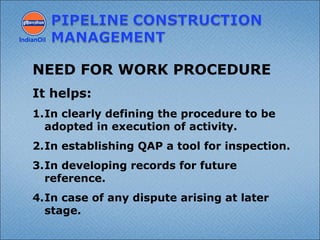

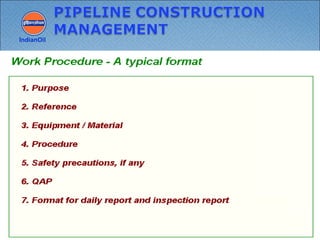

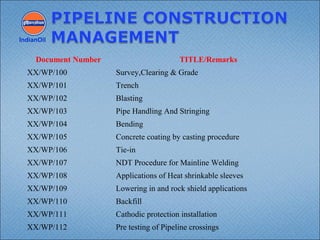

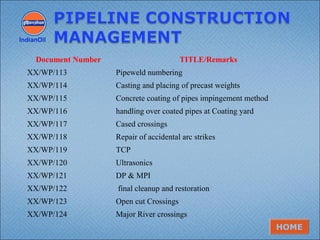

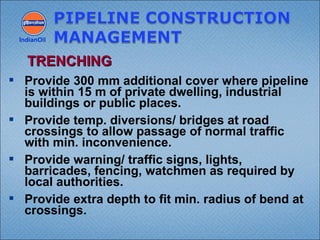

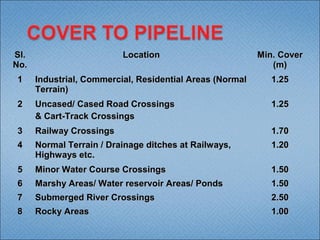

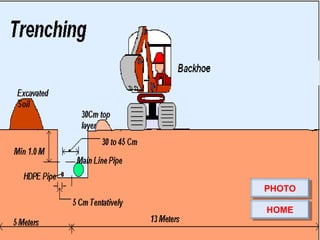

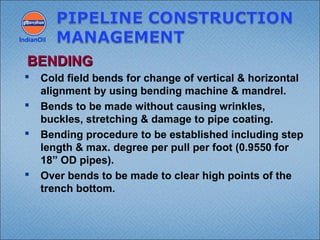

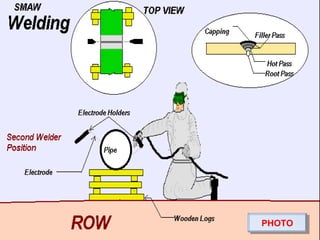

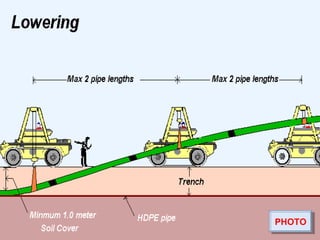

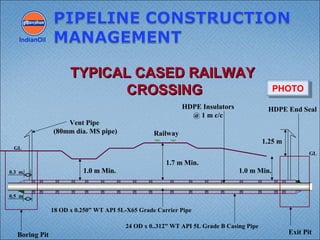

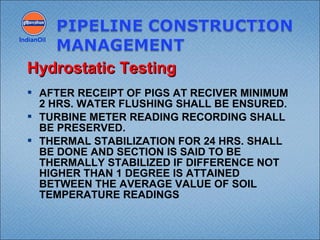

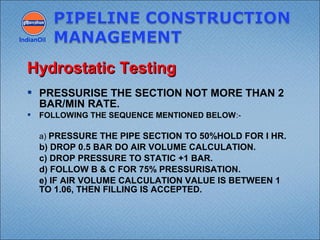

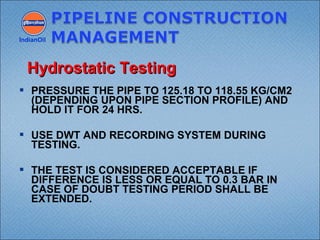

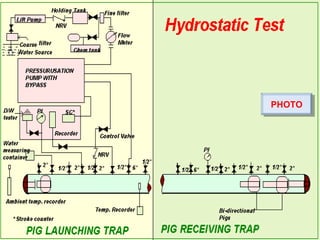

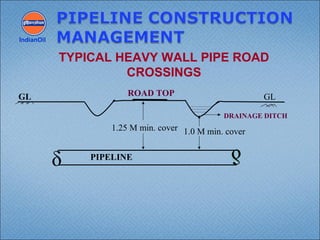

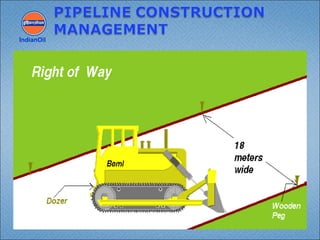

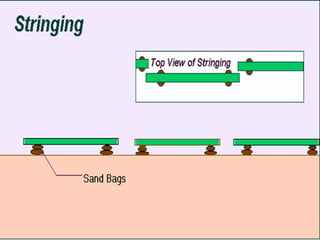

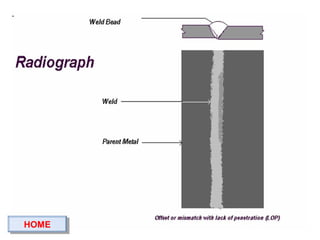

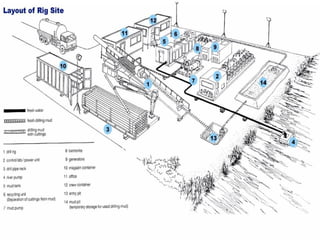

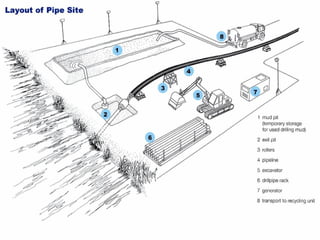

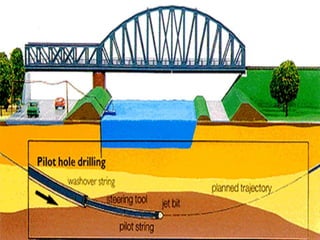

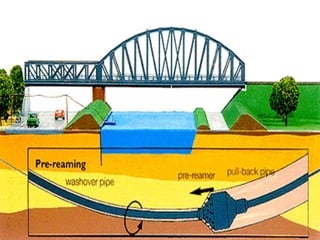

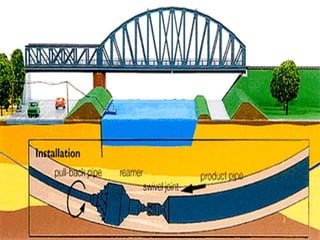

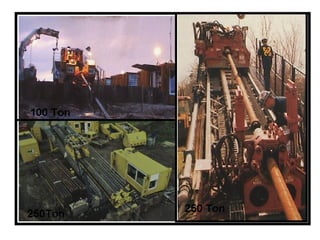

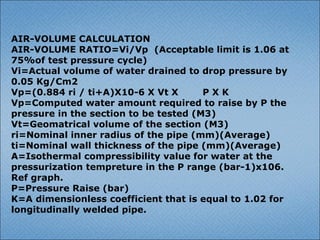

The document describes the procedures for pipeline construction. It involves activities like right of way clearing, trenching, pipe handling, stringing, bending, welding, coating of joints, lowering the pipeline into the trench, backfilling, and hydrotesting. Standard codes and quality checks are specified for each activity to ensure the pipeline is constructed safely and properly.