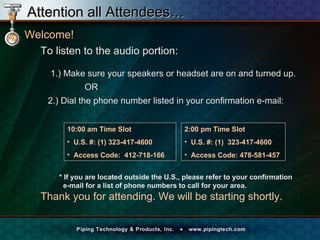

The document serves as an informational guide for attendees of a webinar hosted by Piping Technology & Products, Inc. on the design, application, and installation of pipe clamps. It provides details about the event, including time slots, phone numbers for audio participation, and a list of products offered by the company, such as pipe supports and expansion joints. Additionally, it highlights various types of clamps and their specifications, materials, and applications in the industry.

![PT&P Webinar: Customized Pipe Clamps Please send any additional questions or inquiries to [email_address] Thank You for Attending…](https://image.slidesharecdn.com/pipe-clamps11-18-10webinar-110429084748-phpapp01/85/Pipe-Clamps-Webinar-52-320.jpg)