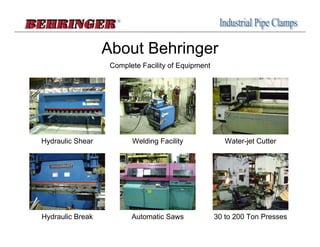

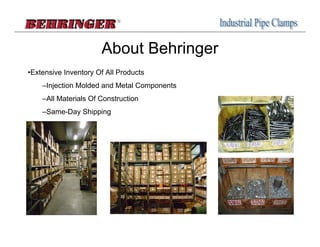

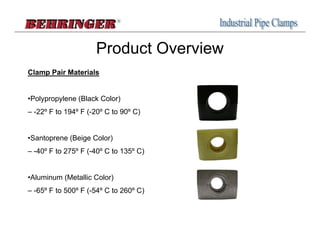

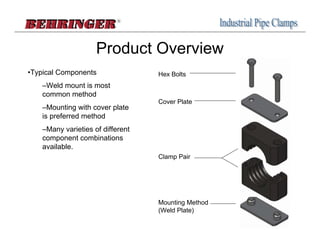

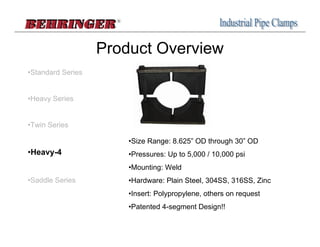

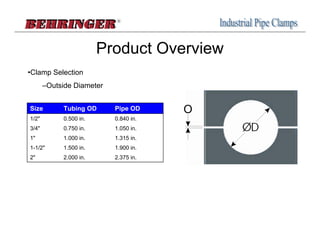

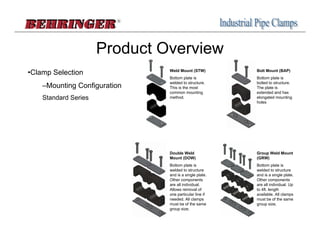

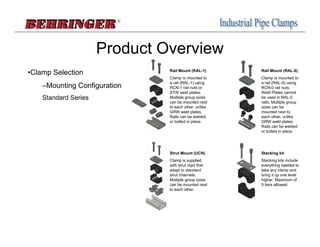

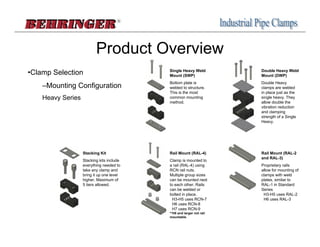

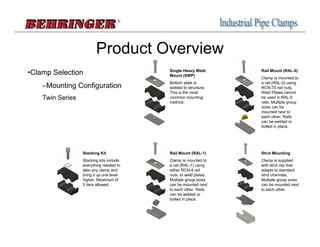

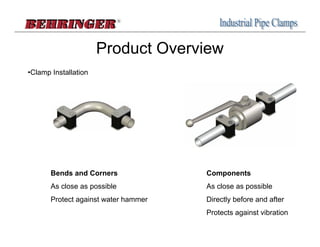

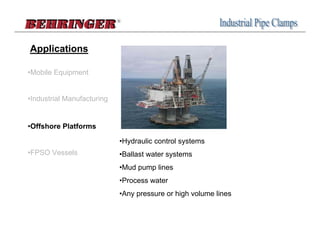

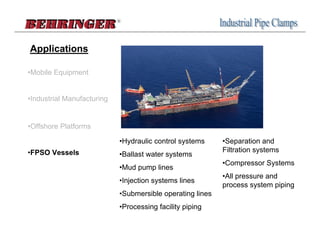

Behringer specializes in manufacturing pipe clamps and tube supports for industrial applications, with a facility located in Branchville, NJ. Their products feature a range of materials and modular insert designs, offering various mounting configurations and size options for effective vibration reduction and noise dampening. Applications span diverse industries including mobile equipment, industrial manufacturing, offshore platforms, and hydraulic control systems.