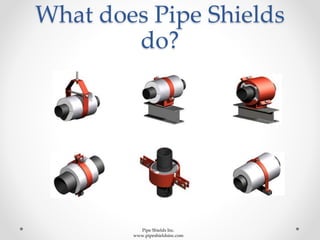

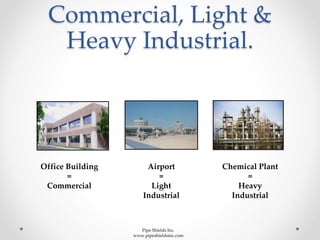

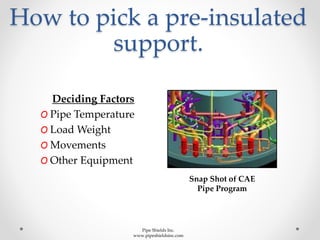

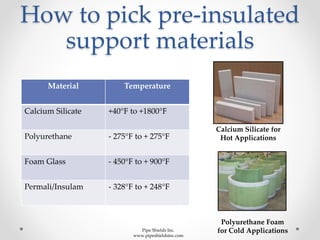

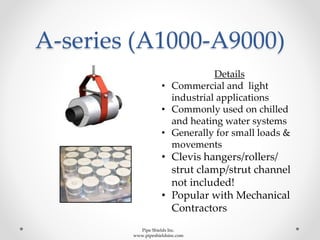

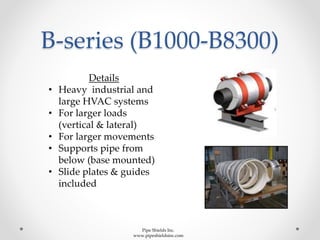

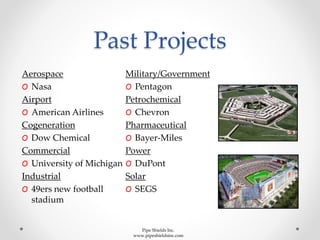

Pipe Shields Inc., led by General Manager Albert Dizon, specializes in engineered products including pre-insulated pipe supports aimed at various industrial applications. Established in 1975, the company boasts over 40 years of experience, certification in ISO 9001-2008, and a diverse product line designed to be energy-efficient and cost-effective. Key benefits of their products include reduced installation costs, low maintenance needs, and innovative designs catered to a range of industrial settings.